Rotor engine

A rotary engine and rotor technology, applied in engine components, combustion engines, machines/engines, etc., can solve problems such as short engine life, high engine fuel consumption, radial seals and cylinder liner inner wall wear, etc. The effect of sufficient combustion and low combustion frequency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

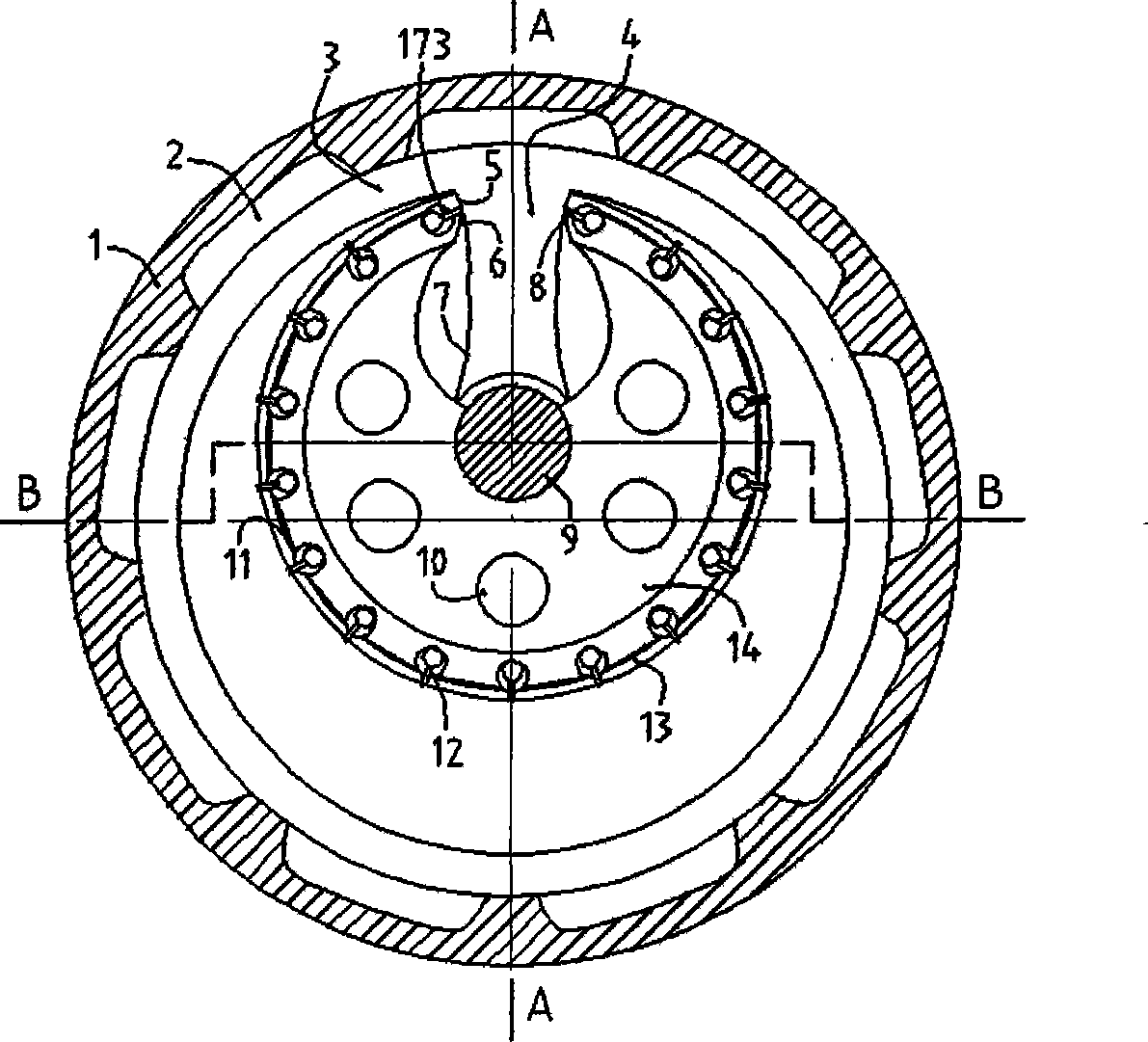

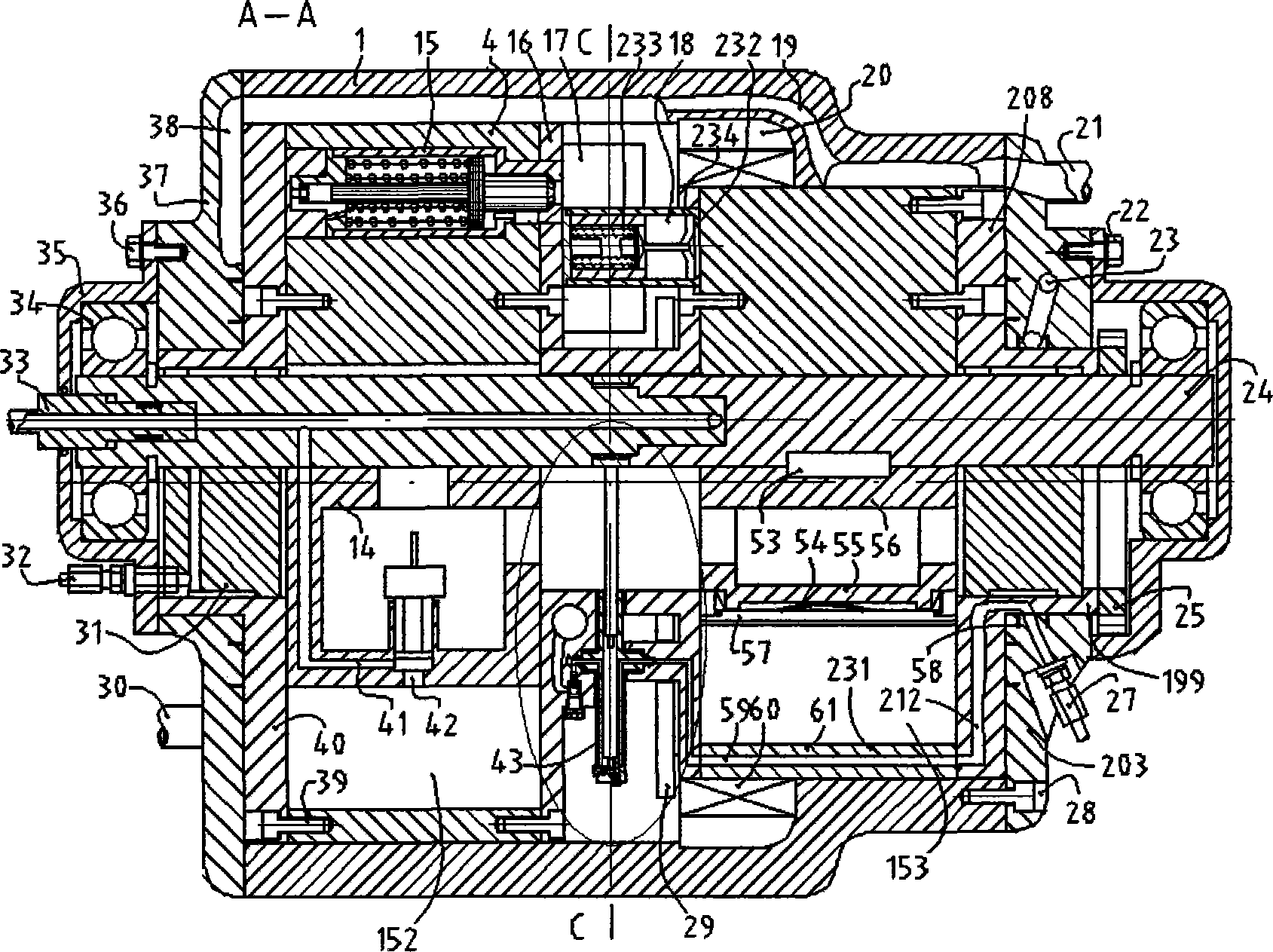

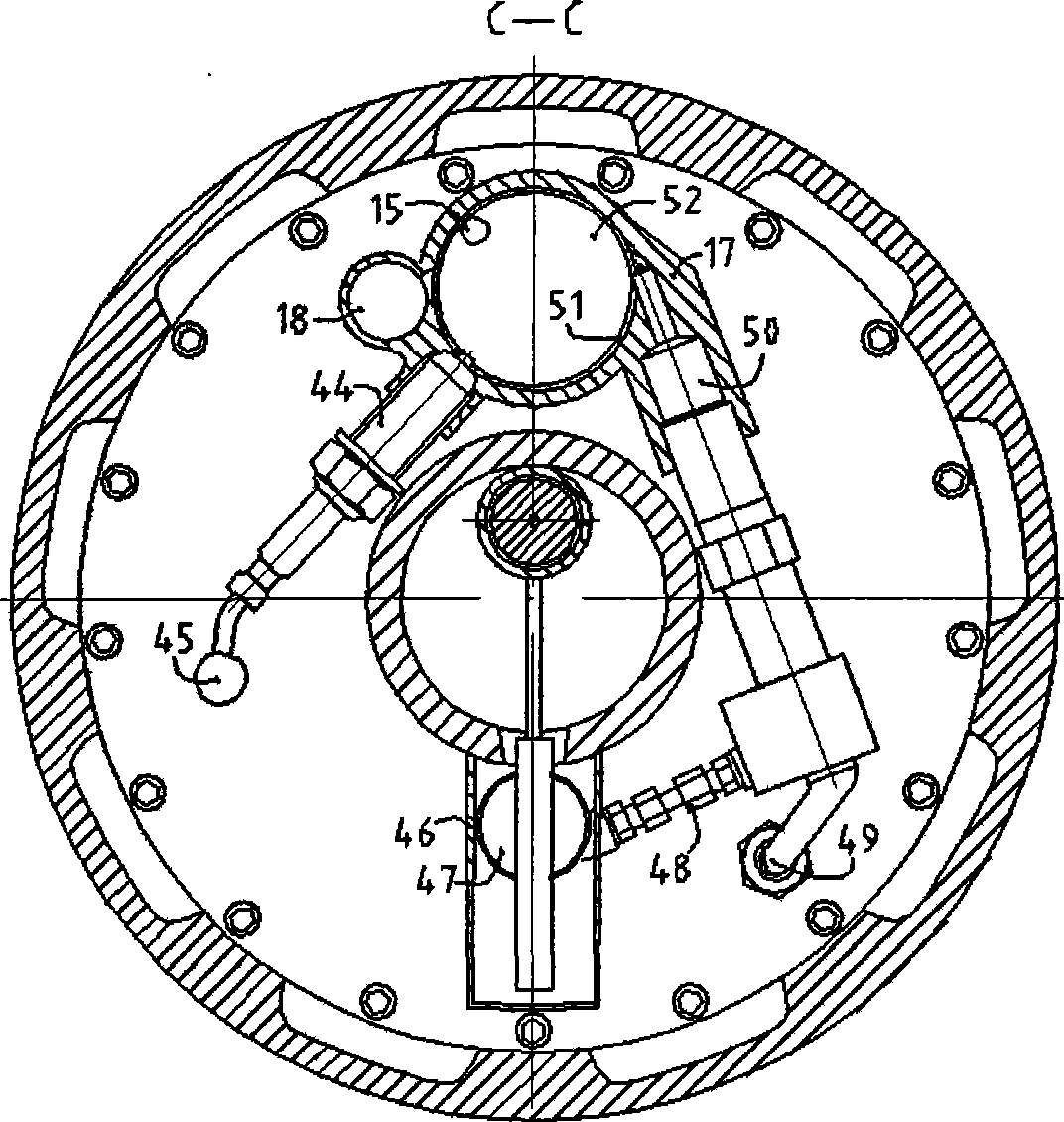

[0041] Such asfigure 1 , 2 , 3, and 4, the rotary engine is composed of a body mechanism, a combustion mechanism, and a compression mechanism:

[0042] The structure of the body mechanism of the described rotor engine is the same as that of the compression mechanism, consisting of a housing 1, a cylinder liner 3, a rotary vane 4, a rotor 14, a seal 12, a main shaft 9, an eccentric shaft 199, a bearing 31, a cylinder liner end cover 40, The casing end cover 37 is composed of the main shaft and the rotor and the key 53 are fixedly matched, the rotor is arranged eccentrically in the cylinder liner, the radial seal 12 is provided on the outer surface of the rotor, and the axial seal 11 is provided on both ends of the rotor . The rear end of the radial sealing sheet is provided with a spring bar 54, and the rear end of the axial sealing sheet is also provided with a spring bar, and these two seals are in contact with each other through the sealing dome; The seals are basically th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com