Backlight module

A backlight module and backplane technology, applied in optics, nonlinear optics, lighting devices, etc., can solve the problems of reduced production capacity, complex rework, etc., and achieve the effects of reduced production costs, large contact area, and good commonality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The technical features of the backlight module of the present invention will be described in detail below with reference to the accompanying drawings.

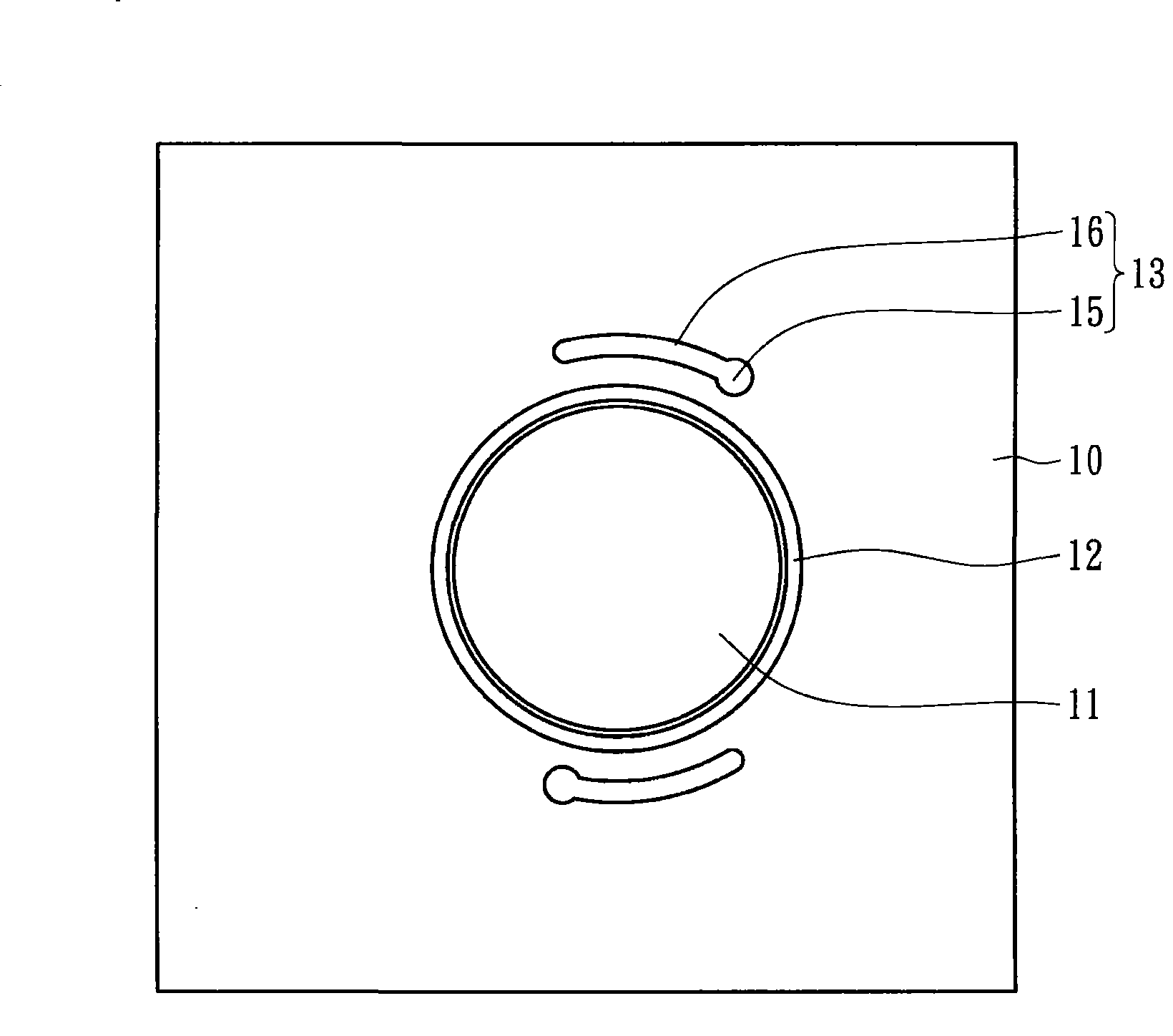

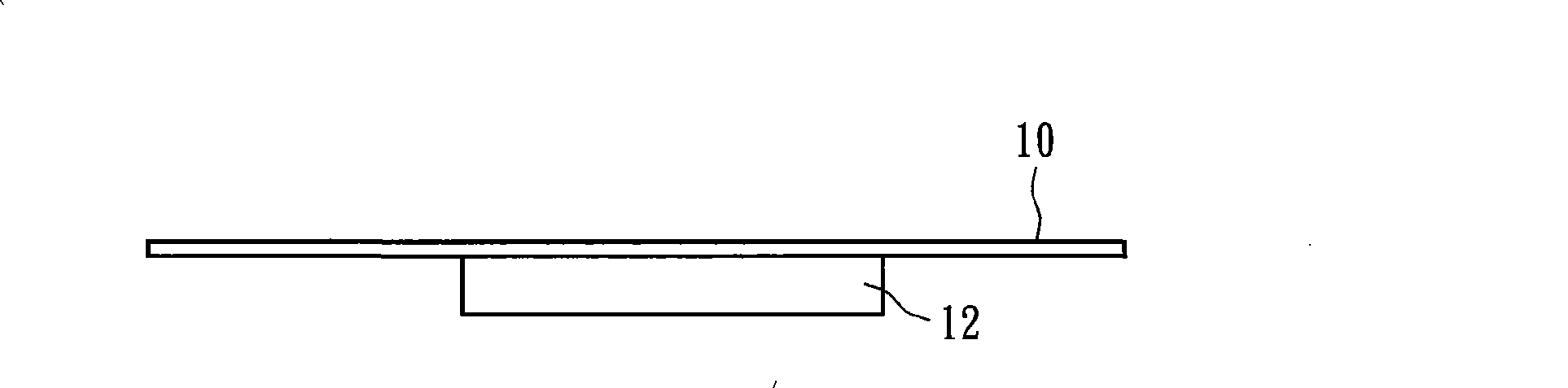

[0040] Figure 1A and 1B It is a top view and a side view of a backplane in a backlight module according to an embodiment of the present invention. The back plate 10 includes a hole 11 , and the hole 11 can be formed by stamping, so that a peripheral edge of the hole 11 protrudes downward to form an extension ring 12 . The two openings 13 are arranged corresponding to each other with respect to the hole 11 . In further words, each opening 13 includes an opening 15 and a slot 16 connected to the opening 15 , and the slot 16 extends along the circular arc periphery of the hole 11 .

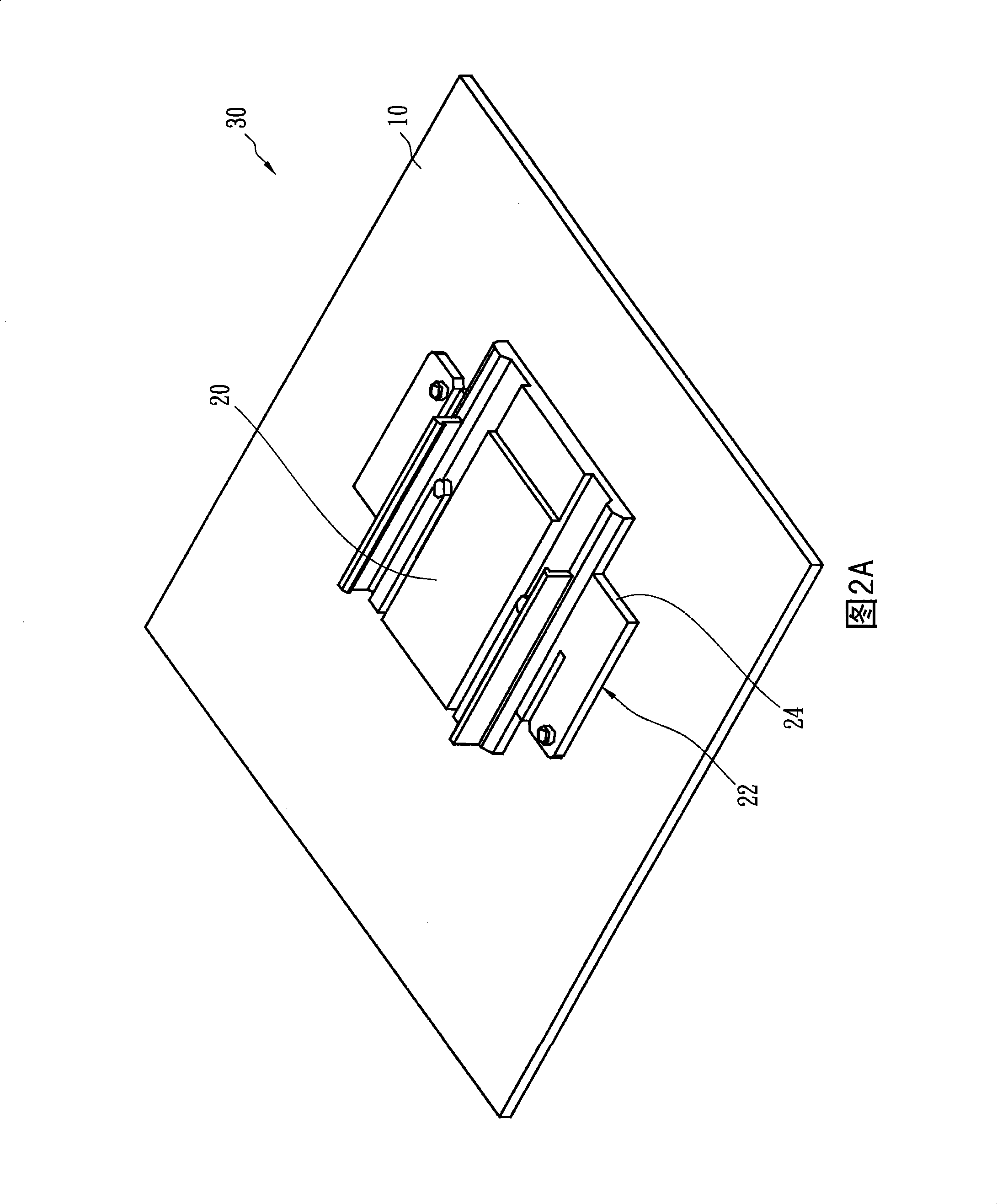

[0041] Figure 2A and 2B It is a three-dimensional schematic diagram of a backlight module including a lamp holder body and a backplane according to an embodiment of the present invention. Figure 2A and Figure 2B The top and bottom p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com