Oar-changing bearing test methods for wind power generator

A technology for wind turbines and pitch bearings, which is applied in the direction of mechanical bearing testing, etc., can solve the problems of affecting the speed of bearing improvement, the cycle and cost of installation and commissioning, and the use performance affecting the safe use of wind power generation equipment, etc., to ensure the qualified efficiency, and the effect of ensuring safe use performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

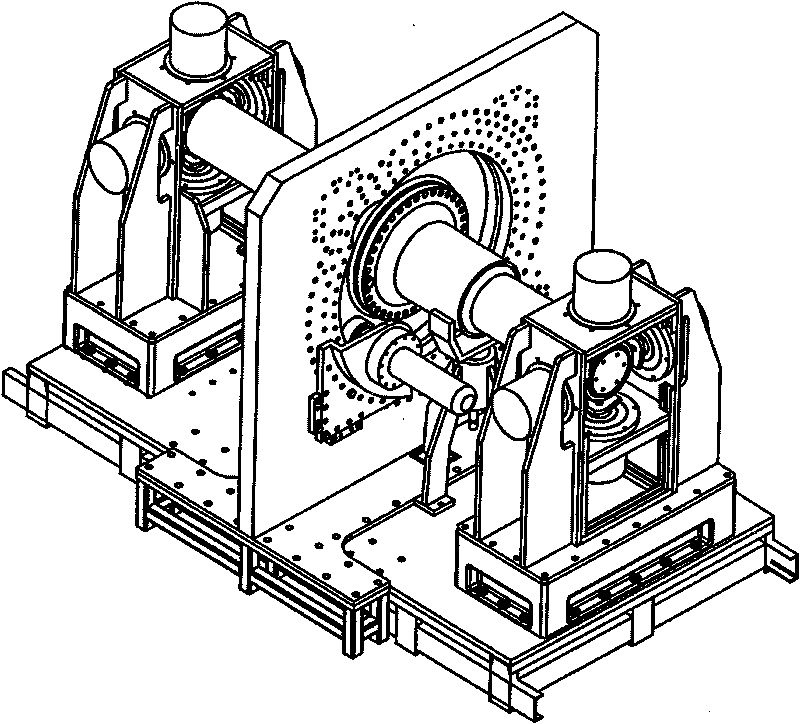

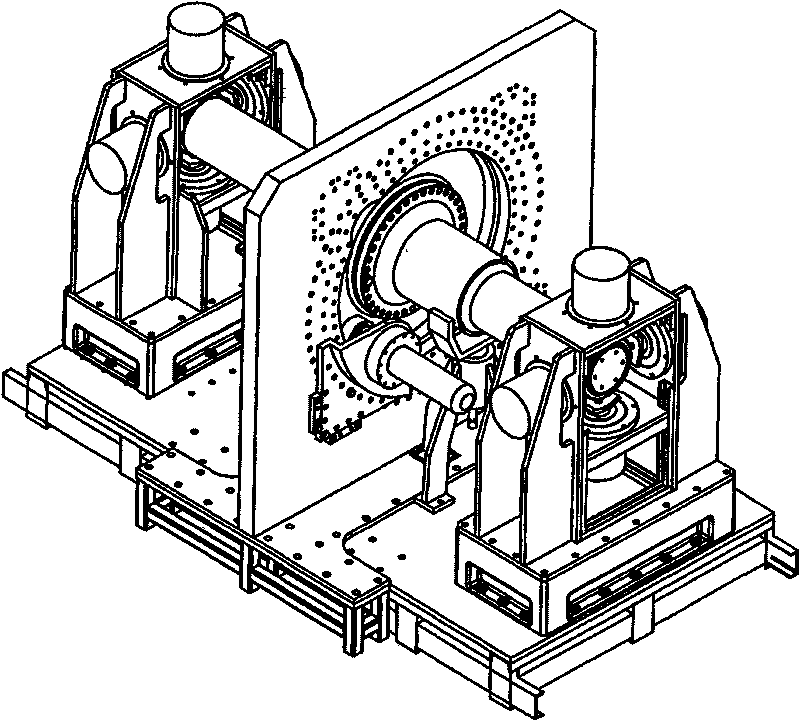

[0027] Such as figure 1 As shown, the test bearing is installed on the wind turbine pitch bearing test machine according to the actual working conditions; the test is divided into three parts:

[0028] The first part: dynamic loading test;

[0029] The second part: static load loading test;

[0030] The third part: dynamic and static load staggered test;

[0031] (1) Dynamic load loading test:

[0032] (1) Carry out 25%, 50%, 75%, 100% dynamic load loading tests, and keep them for 30 minutes respectively, and check whether the connections are loose;

[0033] (2) Carry out running tests under the conditions of 25%, 50%, 75%, and 100% dynamic loads, respectively run for 3 minutes, and run at a speed of 1.5r / min;

[0034] (3) Carry out running tests under the conditions of 25%, 50%, 75%, and 100% dynamic loads, respectively run for 10 minutes, and run at a speed of 1.5r / min;

[0035] (4) Carry out running tests under the conditions of 25%, 50%, 75%, and 100% dynamic loads, r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com