Multifunctional simulation training apparatus for welding

A welding simulation and training device technology, which is applied to the simulation device, simulator, transportation and packaging of space navigation conditions, to achieve the effect of reducing training costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

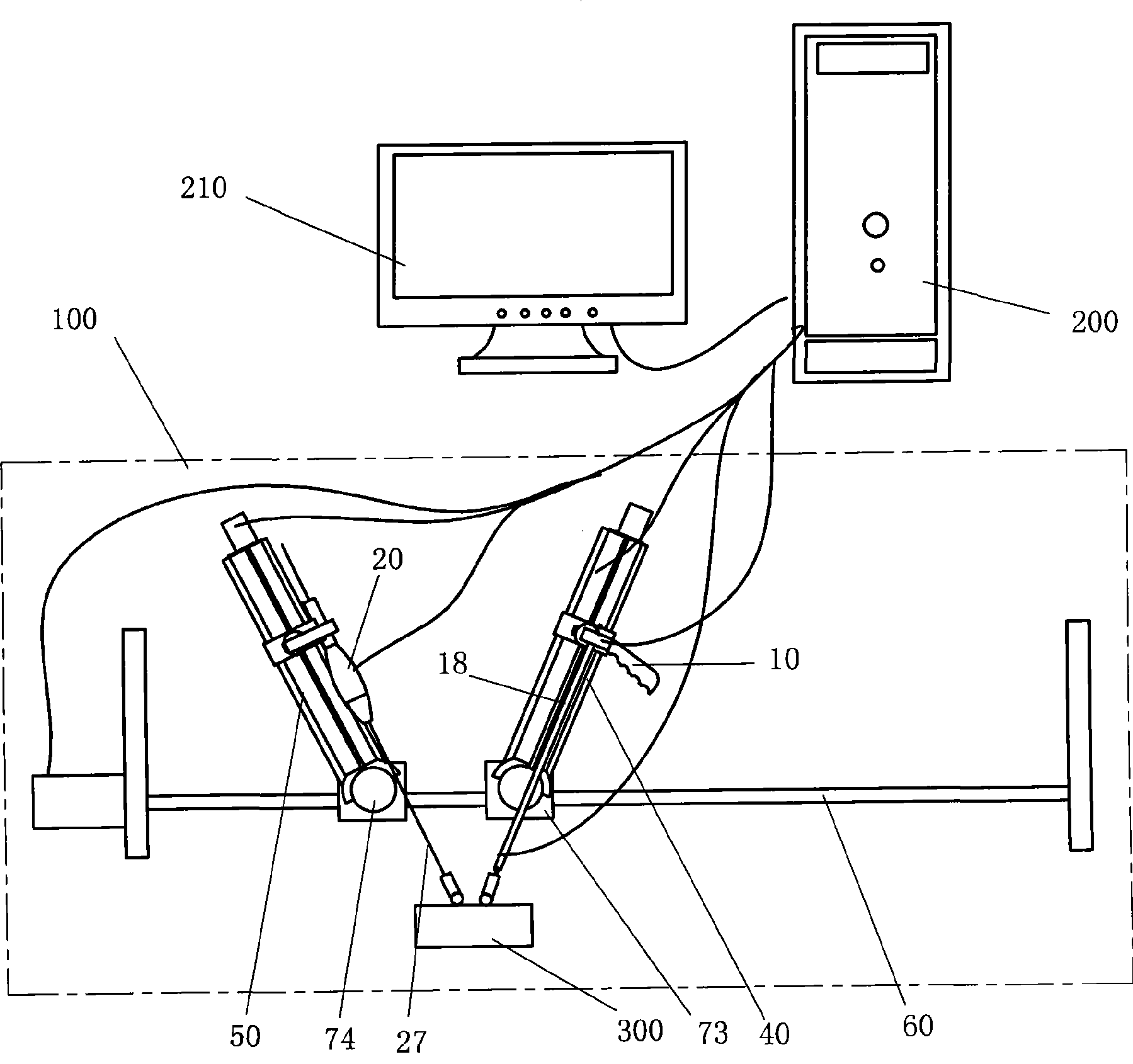

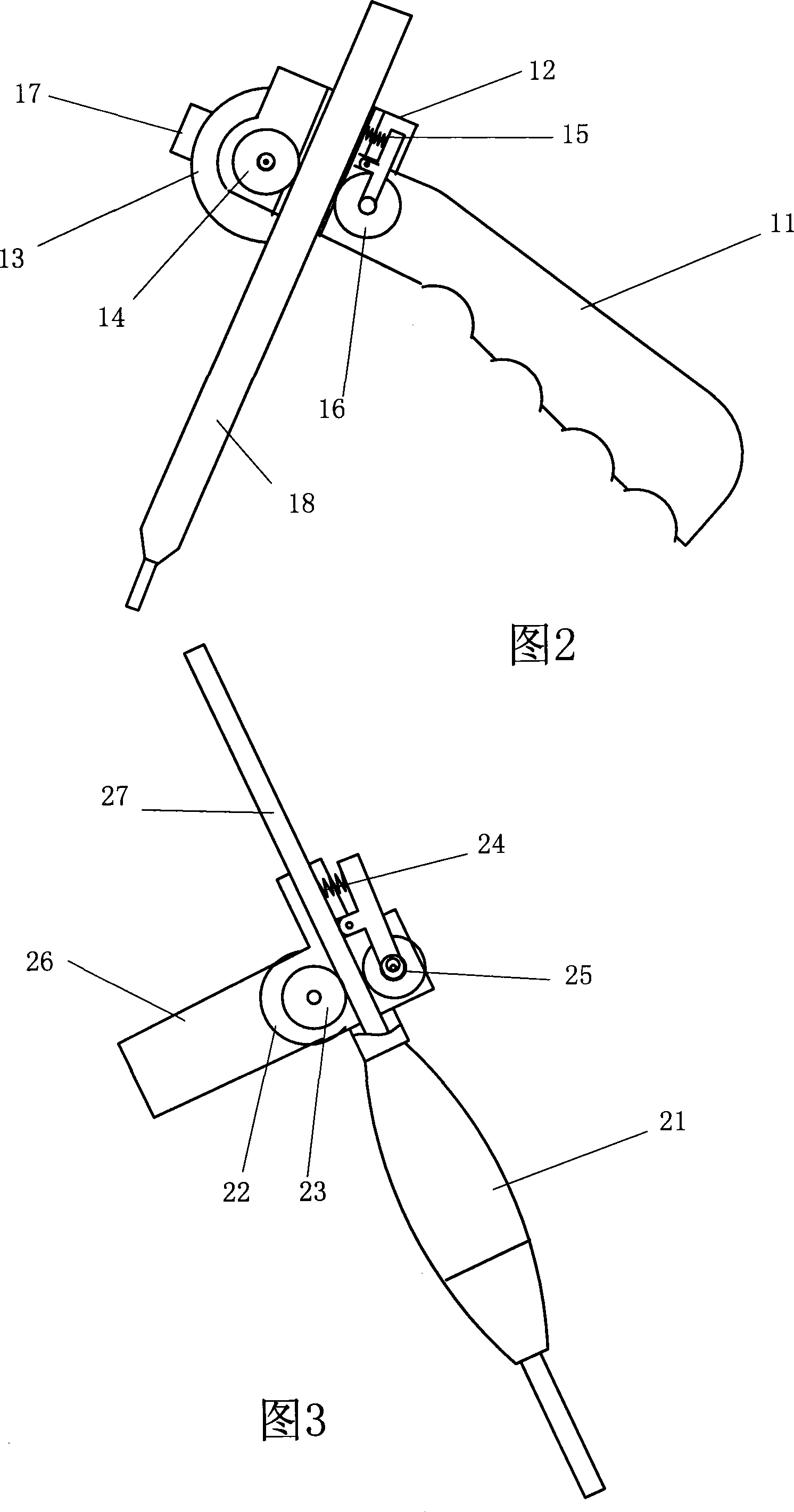

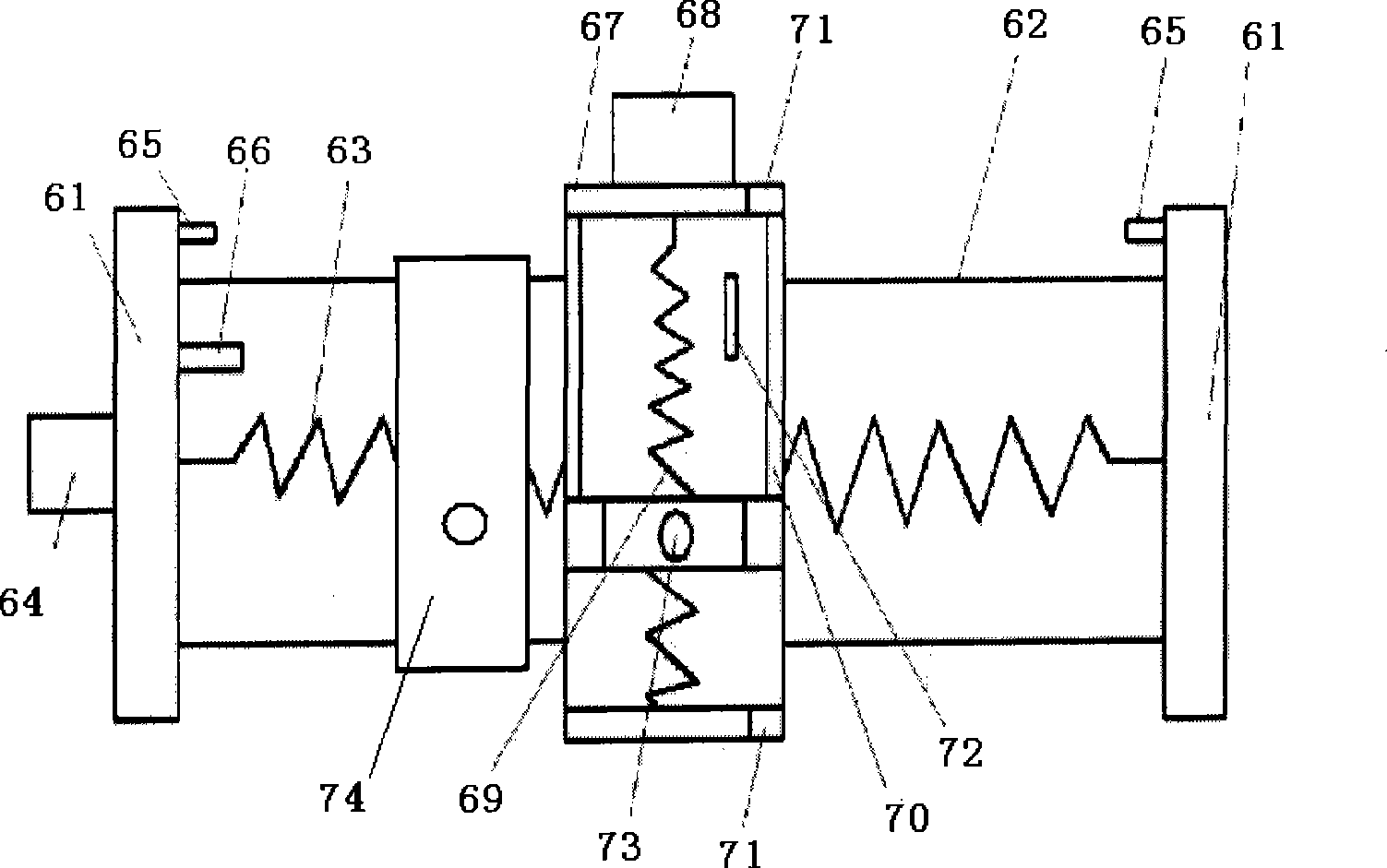

[0046] The invention provides a multifunctional welding simulation training device, the structure of which is as follows: figure 1 As shown, it includes a welding simulator 100 composed of a welding torch handle 10 and a welding wire handle 20, a motion device for driving the welding torch handle 10 and a welding wire handle 20, and a motion trajectory arc length detector 300. The welding torch handle 10 is provided with a simulation The welding rod melting feeding device 11, the welding wire handle 20 is provided with a simulated welding wire melting device 21, a computer controller 200 controls the operation of the welding simulator 100, and accepts the signal of the motion trajectory arc length detector 300, a The display 210 is connected to the computer controller 200, wherein the computer controller 200 stores drivers of welding simulators under various welding methods, different welding positions, and different welding specification parameters; the display 210 displays th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com