Medium pulp for large power thick film circuit and preparation thereof

A technology of dielectric paste and thick film circuit, applied in conductive materials dispersed in non-conductive inorganic materials, etc., can solve problems such as inapplicability, and achieve the effects of high breakdown strength, excellent thixotropy, and high insulation resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

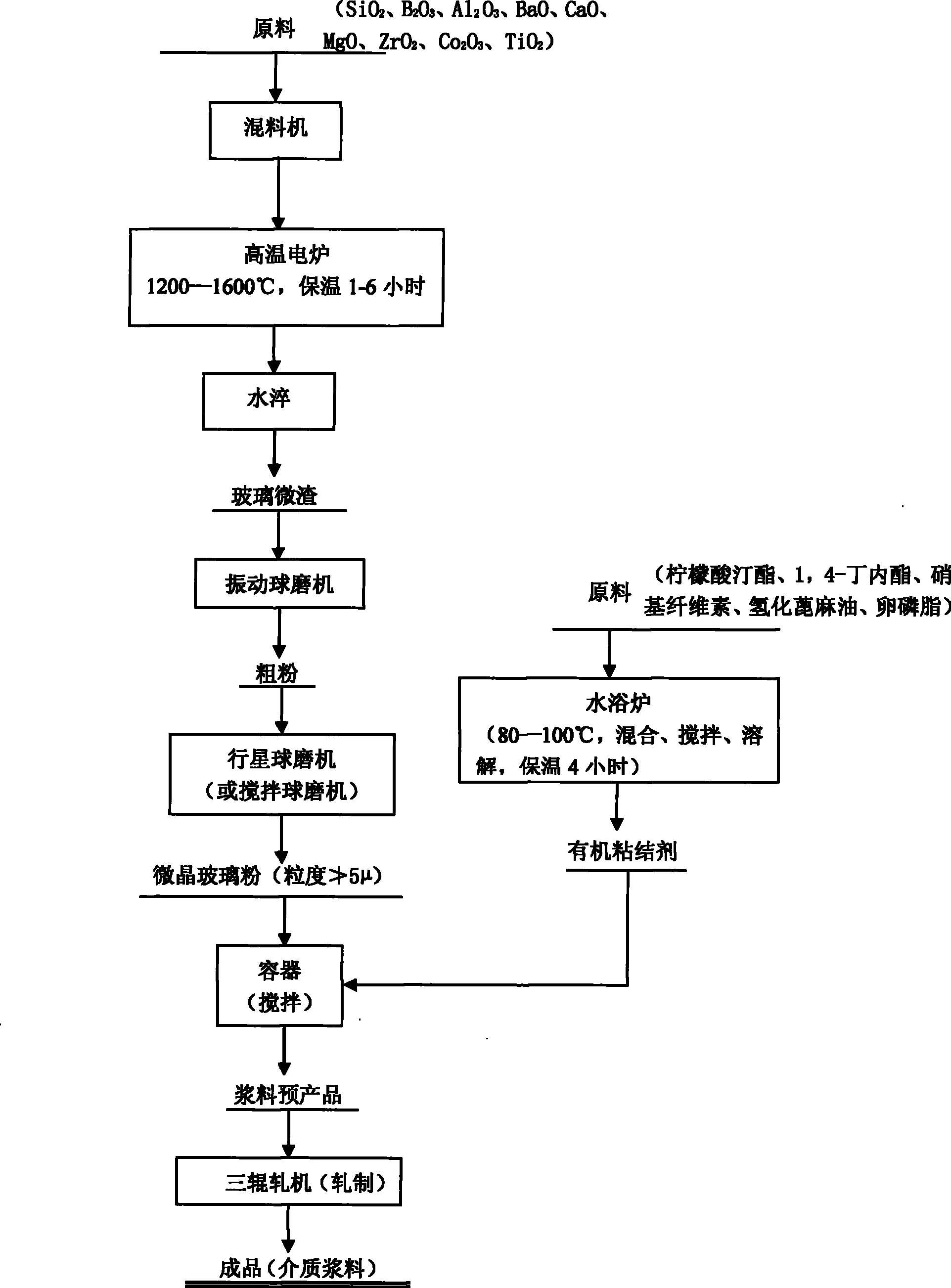

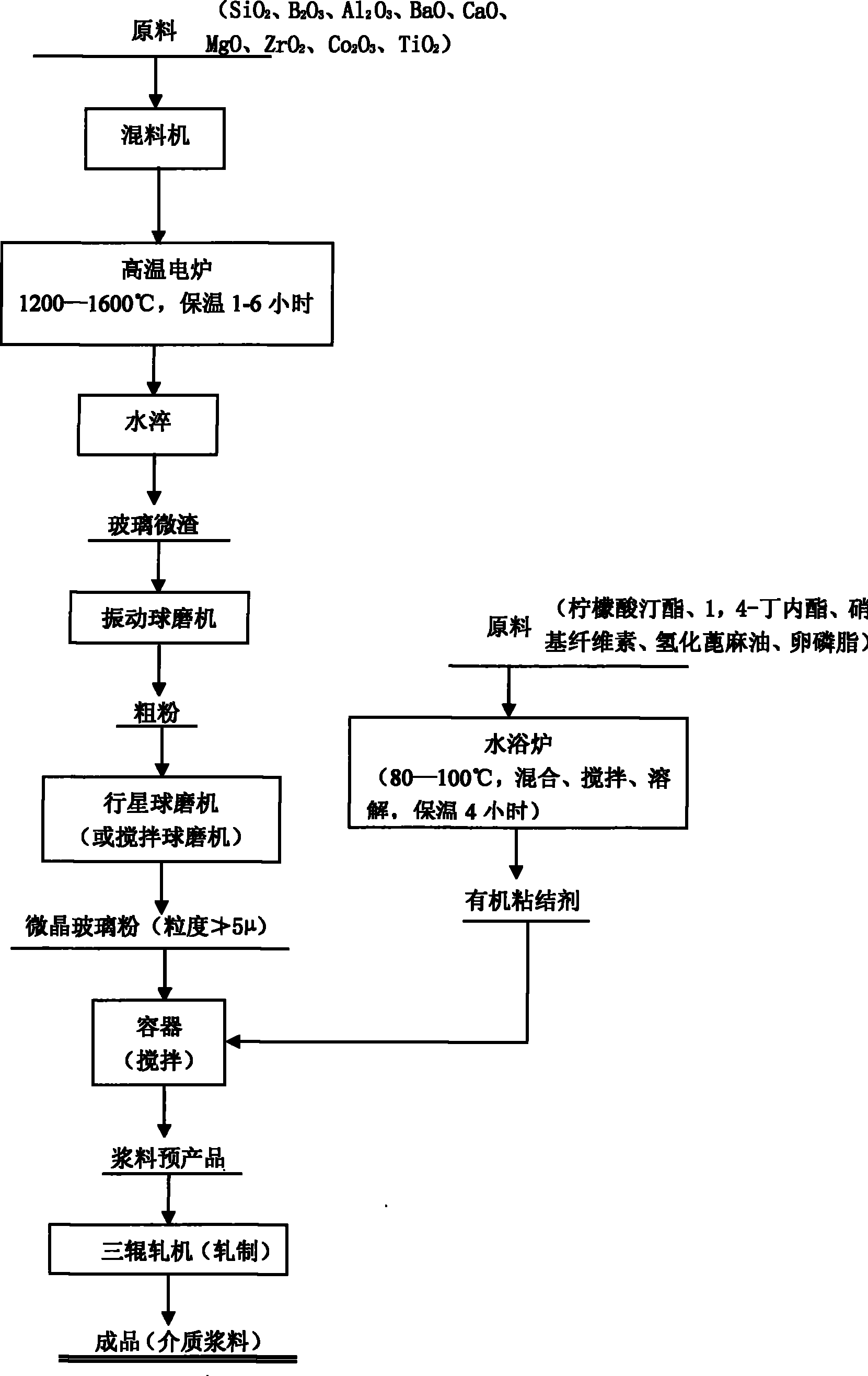

[0020] The preparation method of the dielectric paste for high-power thick film circuit of the present invention is characterized in that the following steps:

[0021] (1) To prepare glass-ceramic powder, mix the components of the glass-ceramic powder in a mixer according to the above-mentioned proportion range, and then put them into a high-temperature furnace for smelting. The melting temperature is 1200-1600° C., and the holding time is 1-6 hours. water quenching to obtain glass micro-slag, and place the glass micro-slag in a ball mill to grind to obtain glass-ceramic powder with a particle size not greater than 5 microns;

[0022] (2) To prepare an organic binder, mix and dissolve the components of the organic binder in a water bath furnace at a temperature of 80-100° C. to form an organic binder and control its viscosity to 200-300mPa s;

[0023] (3) Put the prepared glass-ceramic powder and organic binder in the container according to the above-mentioned ratio range, st...

example 1

[0026] Preparation of glass-ceramic powder, composition and weight ratio of glass-ceramic powder: SiO 2 7 copies, B 2 o 3 3 copies, Al 2 o 3 4 parts, 35 parts of BaO, 5 parts of CaO, 4 parts of MgO, ZrO 2 3 copies, Co 2 o 3 3 parts, TiO 2 1 part; the above composition is placed in a high-temperature electric furnace, the melting temperature is 1350°C, and the temperature is kept for 3 hours. After water quenching, it is coarsely ground with a vibrating ball mill to obtain a coarse powder, and then finely ground with a planetary ball mill or a stirring ball mill to obtain a maximum particle size of no more than 5 micron glass-ceramic powder for use;

[0027] Preparation and dissolution process of organic binder, composition and weight ratio of organic binder: 94 parts of tributyl citrate, 0.3 parts of 1,4-butyrolactone, 5 parts of nitrocellulose, 0.3 parts of hydrogenated castor oil 1 part, 0.4 part of lecithin, the dissolution process is to mix, stir and dissolve...

example 2

[0034] Weight ratio of glass-ceramics: SiO 2 20 copies, B 2 o 3 7 copies, Al 2 o 3 8 parts, 55 parts of BaO, 9 parts of CaO, 7 parts of MgO, ZrO 2 6 copies, Co 2 o 3 5 parts, TiO 2 2 parts; organic binder weight ratio and dissolution process: 89 parts of tributyl citrate, 5 parts of 1,4-butyrolactone, 4 parts of nitrocellulose, 1 part of hydrogenated castor oil, 1 part of lecithin, The dissolution process is to mix, stir and dissolve each composition of the above-mentioned organic binder in a water-bath furnace at a temperature of 90° C., and keep the temperature for 4 hours.

[0035] The weight ratio of glass-ceramic powder and organic binder in the slurry mixing process is 70 parts: 30 parts, and the solid content of the medium slurry of output is 70%, and all the other are the same as example 1

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com