Voltage stabilizing method and device for single phase DC-to-AC converter

A technology of single-phase inverter and voltage stabilization control, which is applied in control/regulation systems, instruments, and irreversible DC power input to AC power output, etc. The effect and other issues, to achieve the effect of high voltage regulation accuracy and fast dynamic response speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

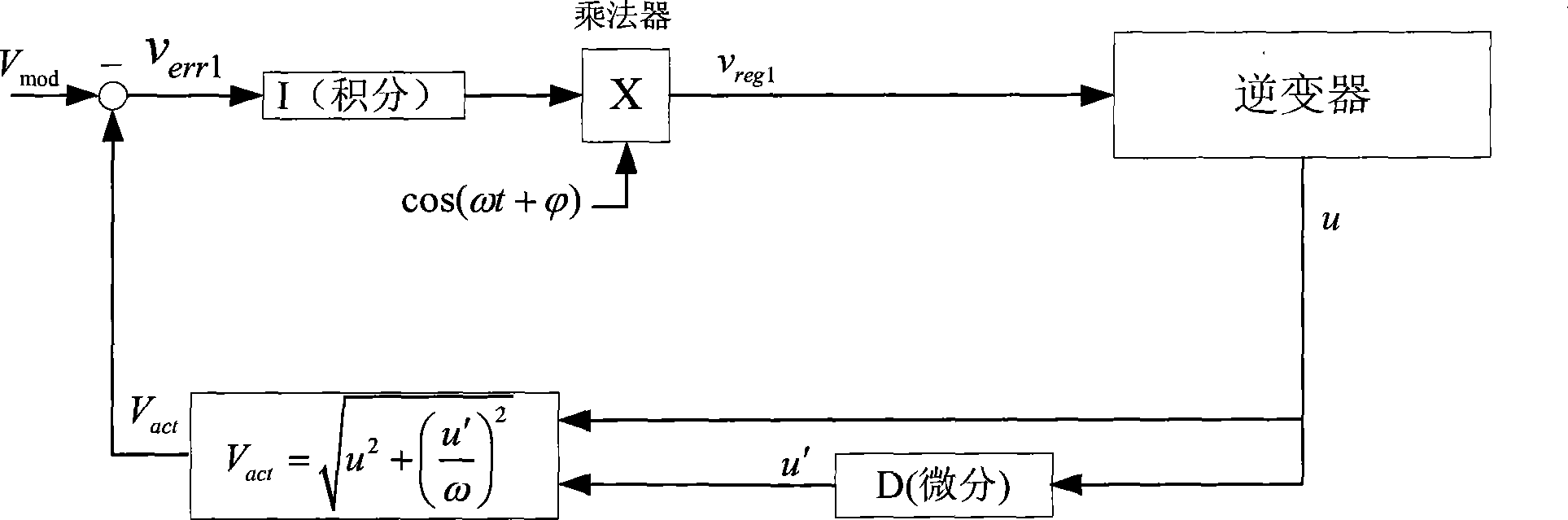

[0031] Such as image 3 As shown, a single-phase inverter voltage stabilization control method includes the following steps:

[0032] Step 1: Obtain the actual output voltage modulus of the single-phase inverter. The specific operation is as follows: collect the instantaneous value u of the output voltage of the single-phase inverter, obtain the output voltage change rate u′ of the single-phase inverter, according to V act = u 2 + ( u ′ ω ) 2 Get the actual output voltage modulus of the single-phase inverter, where V act is the actual output voltage modulus of the single-phase inverter, u is the instantaneous value of the output voltage of the single-phase inverter, u' is the rate of c...

specific Embodiment approach 2

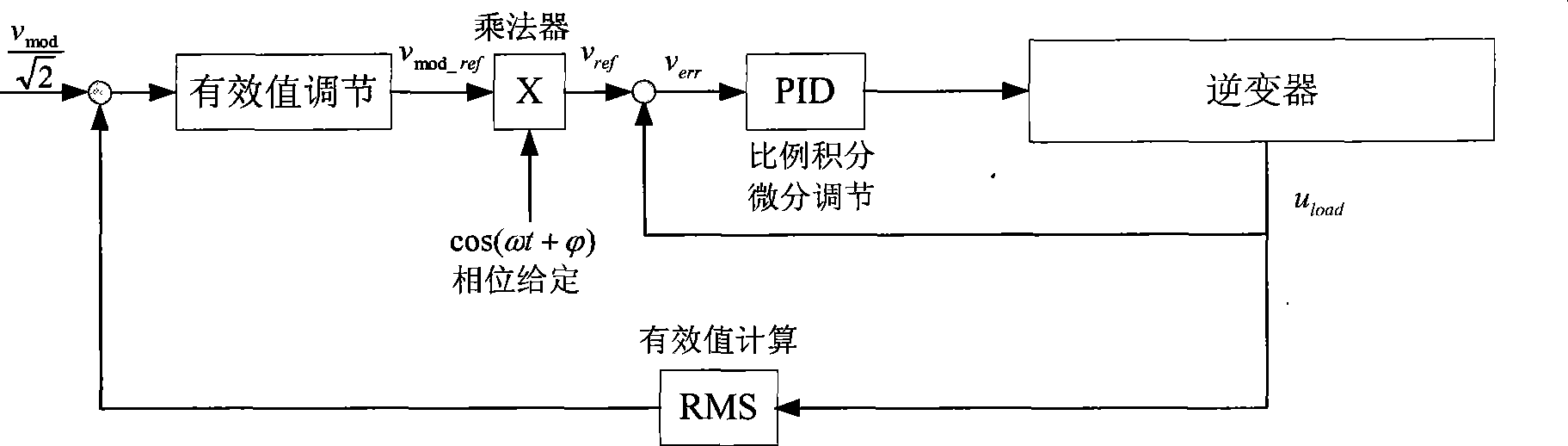

[0047] Such as Figure 6 As shown, the difference between this specific embodiment and the first specific embodiment is that the voltage instantaneous value adjustment is added. This embodiment also includes the following steps:

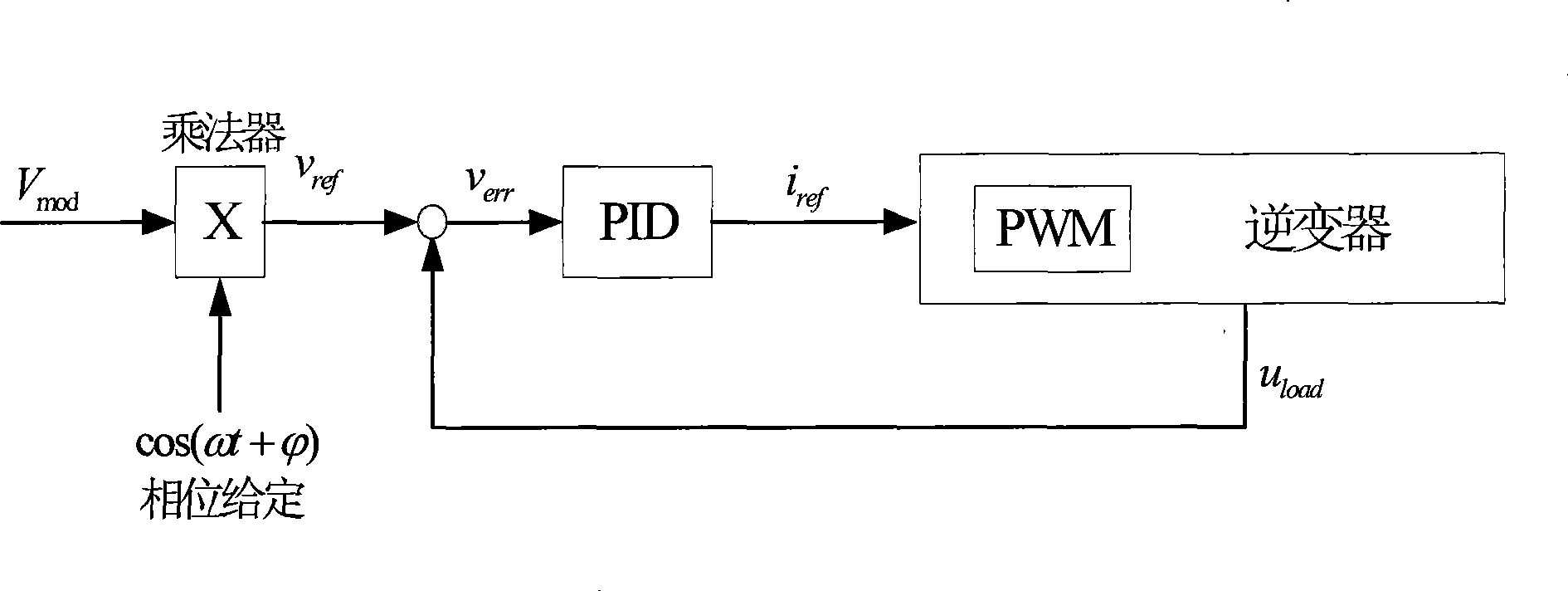

[0048] Step 4: Obtain the instantaneous value of the given voltage of the single-phase inverter. The multiplier moduloes the voltage to a given V mod The cosine value cos(ωt+ ) multiplied to obtain the instantaneous value of the given voltage v ref .

[0049] Step 5: Obtain an error of the instantaneous voltage according to the instantaneous value of the output voltage of the single-phase inverter and the instantaneous value of the given voltage. Use a subtractor to convert the instantaneous value of the given voltage v ref Subtract the actual instantaneous voltage u to get the error v of the instantaneous voltage err2 .

[0050] Step 6: According to the error of the instantaneous voltage v err2 is adjusted to obtain a second adjustment amo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com