Double-diaphragm pressure stabilizer

A technology of voltage stabilizer and diaphragm, applied in the direction of safety valve, engine element, balance valve, etc., can solve the problems of voltage stabilizer failure, valve stem jam, increase unbalanced force of valve core, etc., to achieve stable voltage High precision, sensitive action and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] First of all, it needs to be explained that the orientation words such as up, down, left, right, front, and back described in the present invention are only described according to the accompanying drawings, so as to be easy to understand, and are not intended to limit the technical solution and scope of protection of the present invention. .

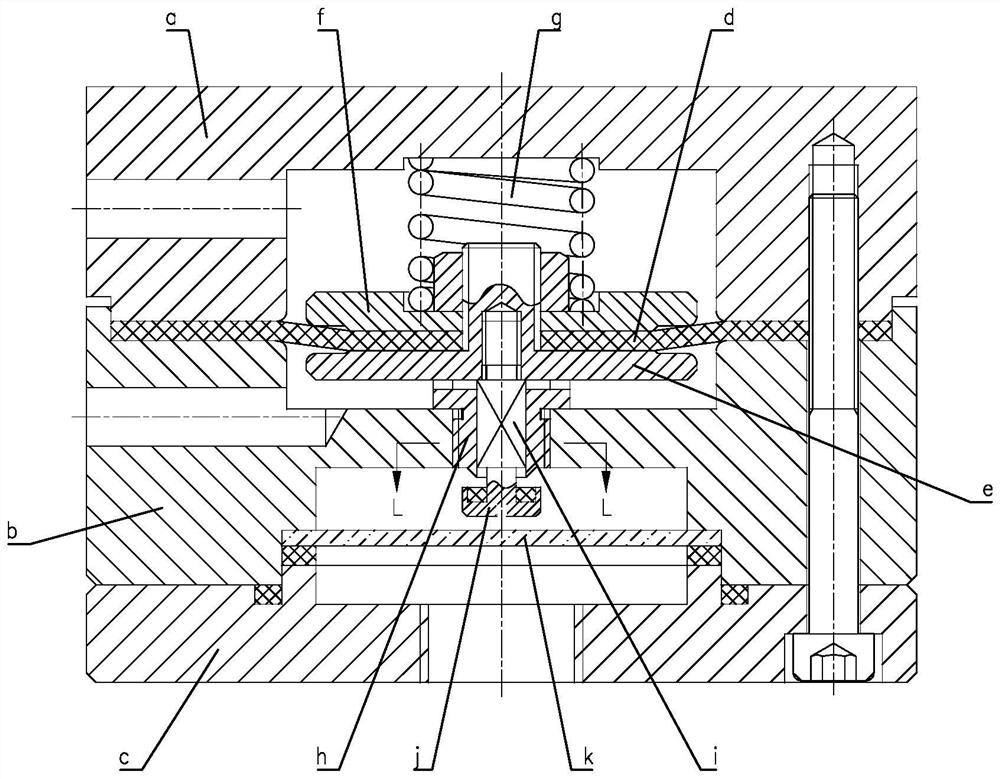

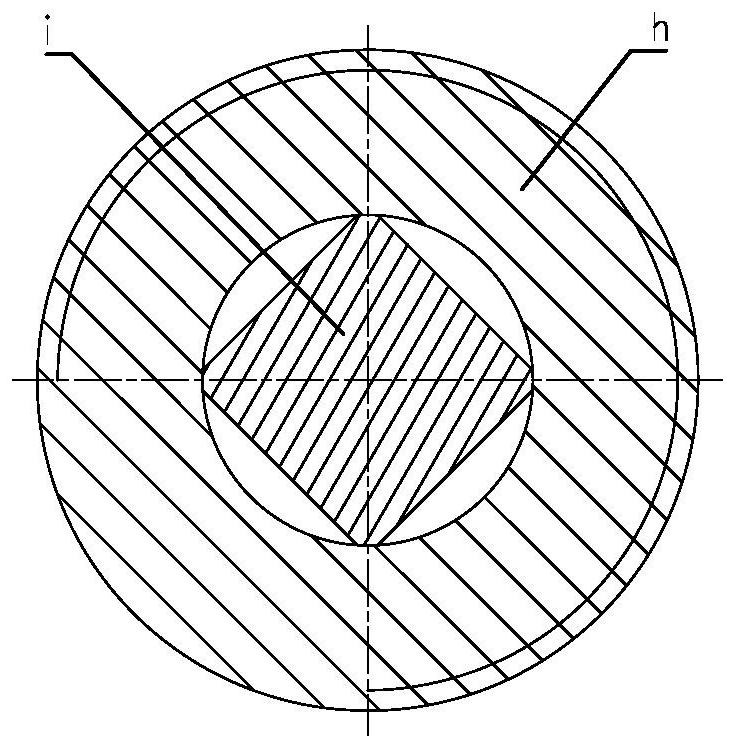

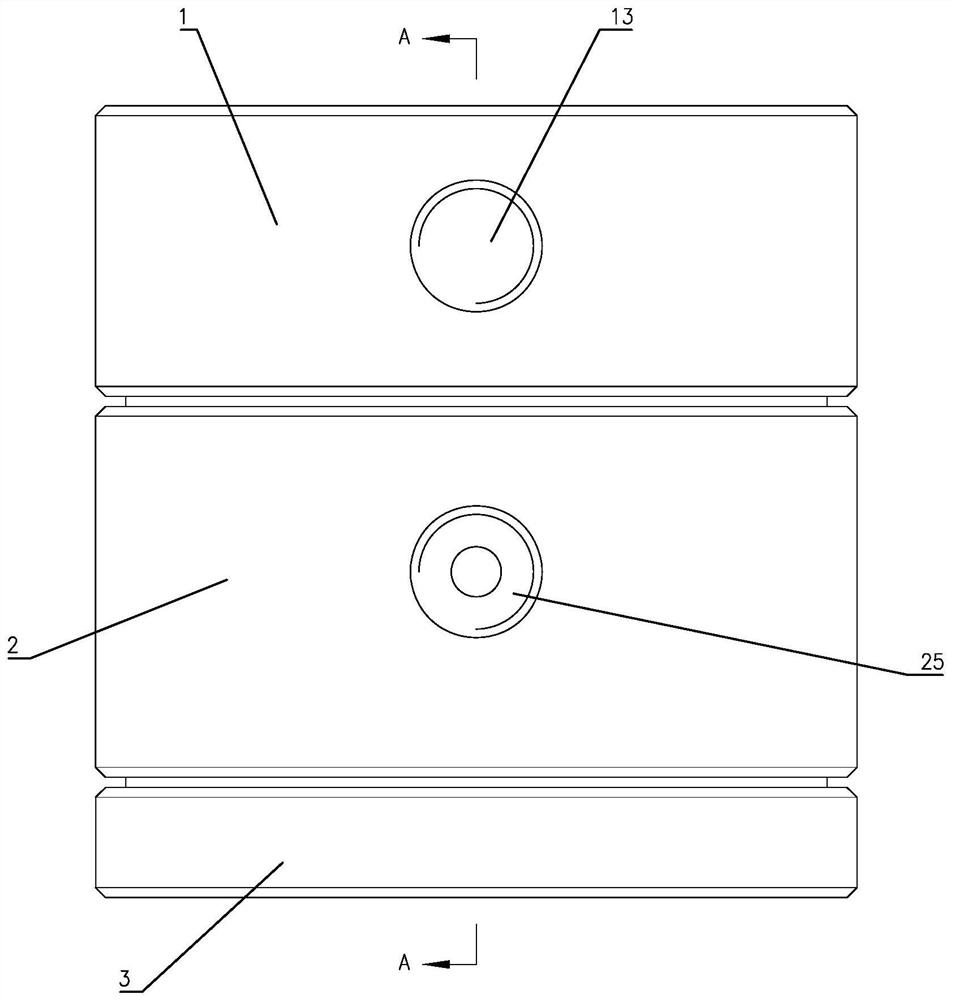

[0023] Such as Figure 3 to Figure 7 Shown is a specific embodiment of a double-diaphragm regulator of the present invention, including an upper cover 1 , a valve body 2 and a lower cover 3 arranged in sequence from top to bottom. The upper cover 1 is provided with a first groove 11 and a first receiving groove 12 from bottom to top, and a first air inlet 13 communicating with the first receiving groove 12 is arranged on the left side of the upper cover 1 . The valve body 2 is provided with a second groove 21 and a third groove 22 correspondingly on the upper and lower sides. A valve port 24 is provided, a second air inlet 25 co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com