Composite multifunctional slipper mechanism

A multi-functional, slider technology, applied to mechanical equipment, engine components, valve details, etc., can solve problems such as inability to perform overflow and overflow ejection, single function of mold slider, and only core pulling and demoulding.

Inactive Publication Date: 2010-12-01

NINGBO SUNNY MOLD

View PDF6 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The purpose of the present invention is to solve the problem that the function of the mold slider in the injection molding equipment is single, and it can only complete the function of core pulling and demoulding, but cannot perform overflow and overflow ejection. The overflow mechanism and the overflow ejection mechanism are set inside, which not only has the core-pulling and demoulding function of the slider, but also has the composite multifunctional slider mechanism with the overflow function and the overflow ejection function during gas-assisted molding, which solves the problem of gas The flashing process in the auxiliary molding can set different flashing positions, which expands the freedom of product design, increases the utilization rate and function of the mold structure, and solves the problem of flashing in different directions at the same time

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

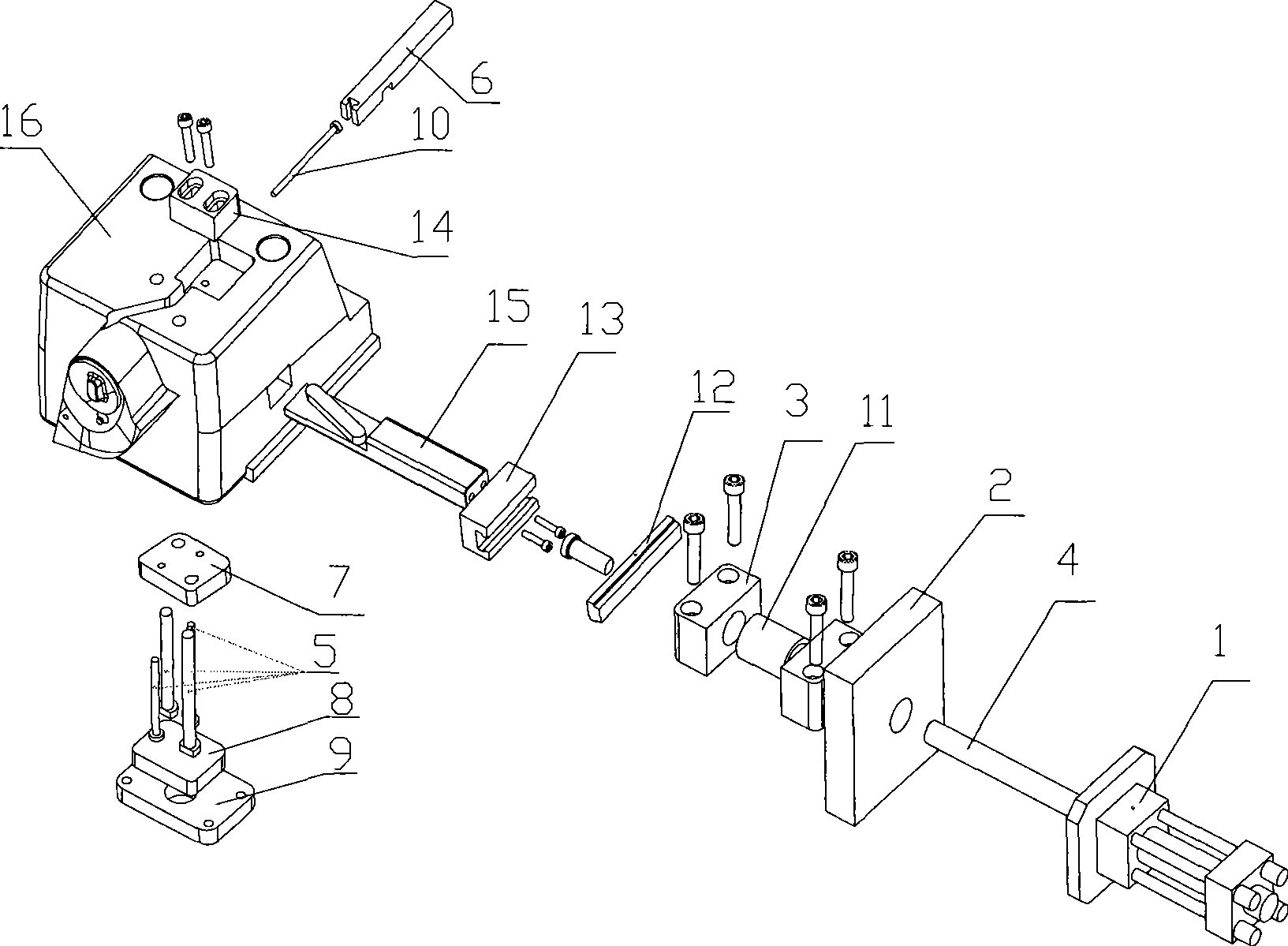

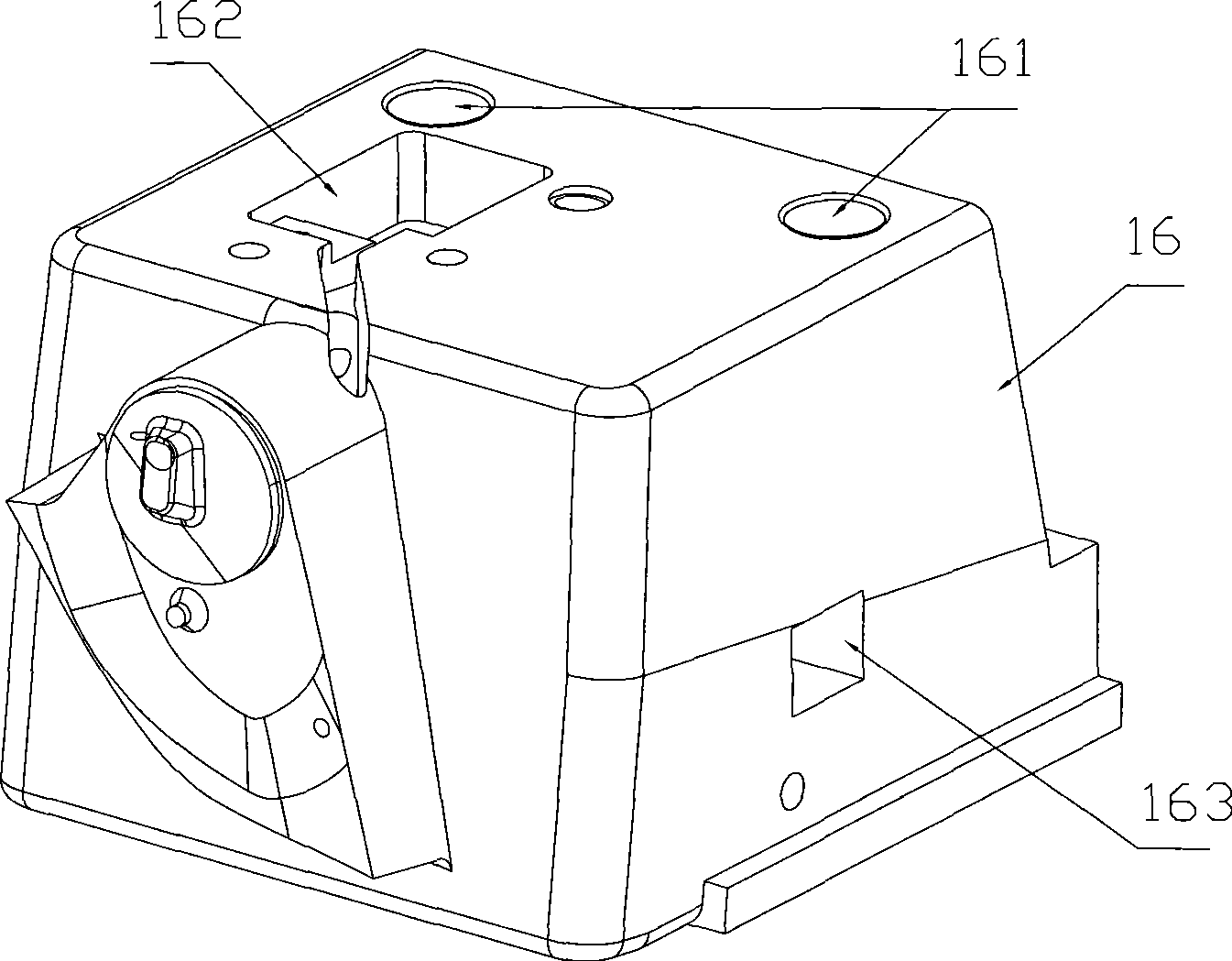

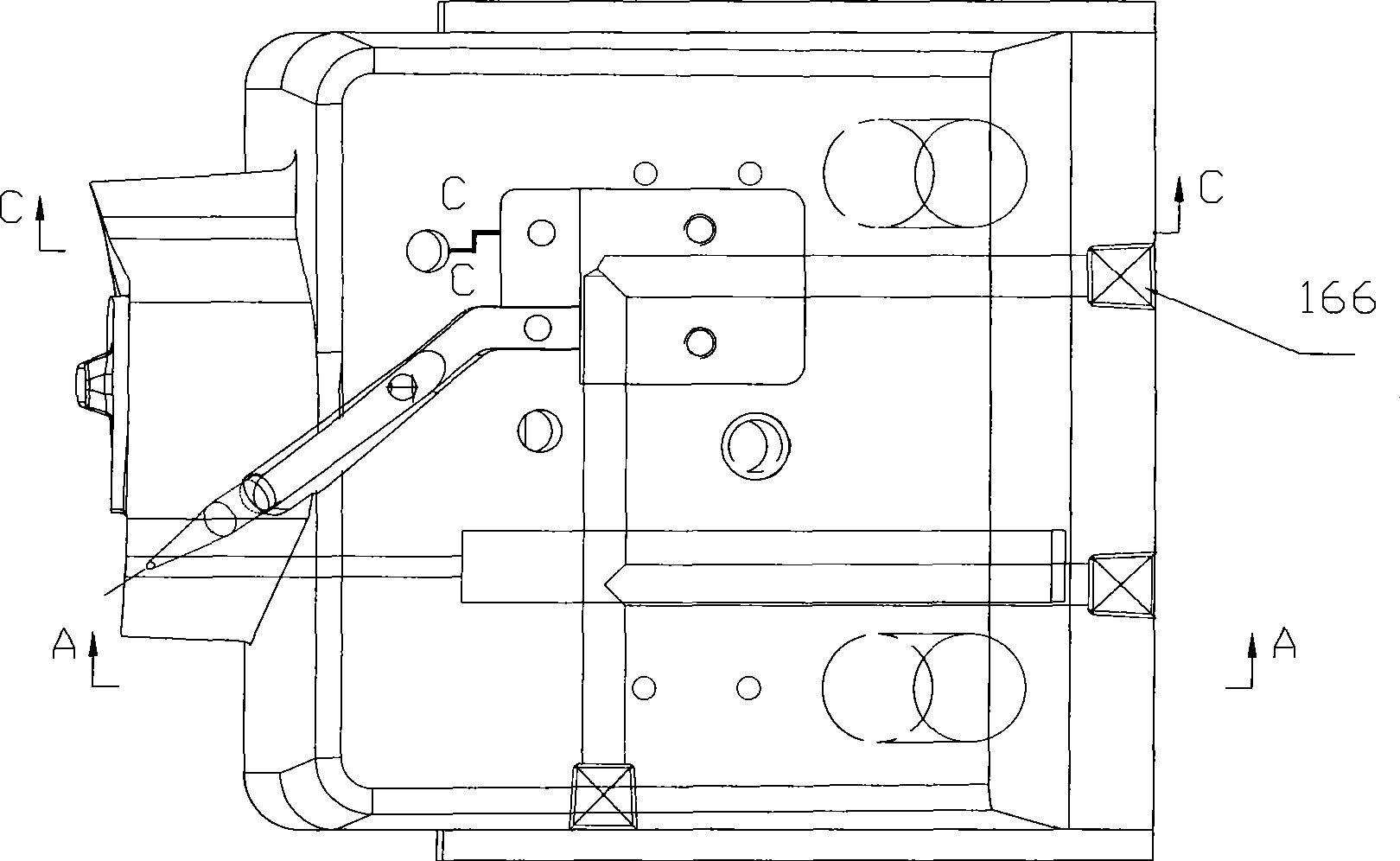

The invention relates to a composite structure with the function of a sliding block of an injection equipment mold, in particular to a composite multi-function slider mechanism, which is provided with a flash mechanism and a flash ejection mechanism in the sliding block and has both the flash function and the flash ejection function in gas-assisted molding, simultaneously, the core-pulling and demoulding function of the sliding block. The slider mechanism comprises a mold body, a core plate and a sliding block body, on which the flash mechanism and the flash ejection mechanism are arranged; the flash mechanism comprises a flash valve and a hydraulic drive mechanism, the flash valve is installed in the sliding block body and the hydraulic drive mechanism is fixed on the core plate of the mold body; the auxiliary ejection rod in the flash ejection mechanism is arranged in the main ejection system of the mold. The composite structure solves the problem that different flash position points can be arranged in the flash procedure of gas-assisted molding, expands the freedom degree of product design, increases the utilization rate and functions of the mold structure and also solves the anisotropic flash problem.

Description

Composite Multifunctional Slider Mechanism technical field The invention relates to a compound structure with the function of a mold slide block of injection molding equipment, in particular to an overflow mechanism and an overflow ejection mechanism provided in the slide block, which not only has the core-pulling and demoulding function of the slide block, but also has a gas Composite multifunctional slider mechanism that assists flashing function and flashing ejection function during molding. Background technique In the mold of injection molding equipment, the function of the general slider in the mold structure is mainly to realize the undercut demoulding of the product after injection, and the driving force of its movement comes from machinery (such as inclined guide pillars, T-shaped guide blocks, etc.) or Hydraulic drive, the compound function of the relatively newly designed slider is mainly manifested in that the function of the slider is increased as the driving f...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): B29C45/26F16K31/122B29C45/17B29C45/33

Inventor 杨世洪

Owner NINGBO SUNNY MOLD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com