Screw rod follow-up supporting mechanism of lifting device

A supporting mechanism and lifting device technology, which is applied in the direction of lifting equipment safety devices, lifting devices, etc., can solve problems such as safety restrictions on heavy-duty jacking, and achieve the effects of avoiding heavy-load slipping, simple structure, and ensuring safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Below the present invention will be further described in conjunction with the embodiment in the accompanying drawing:

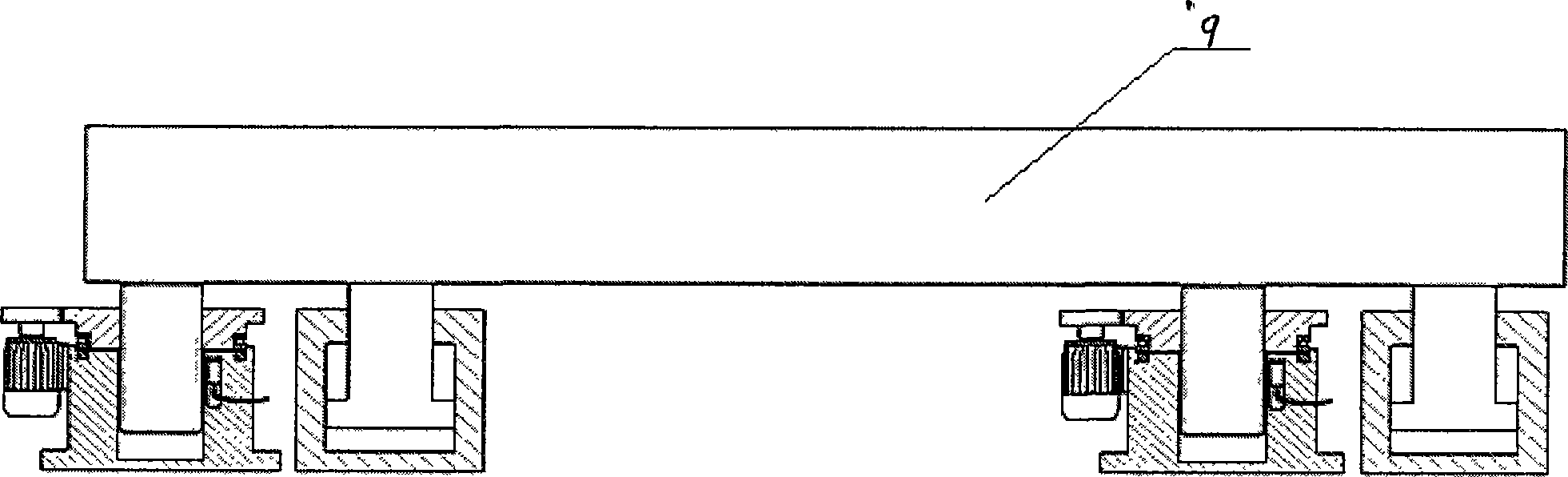

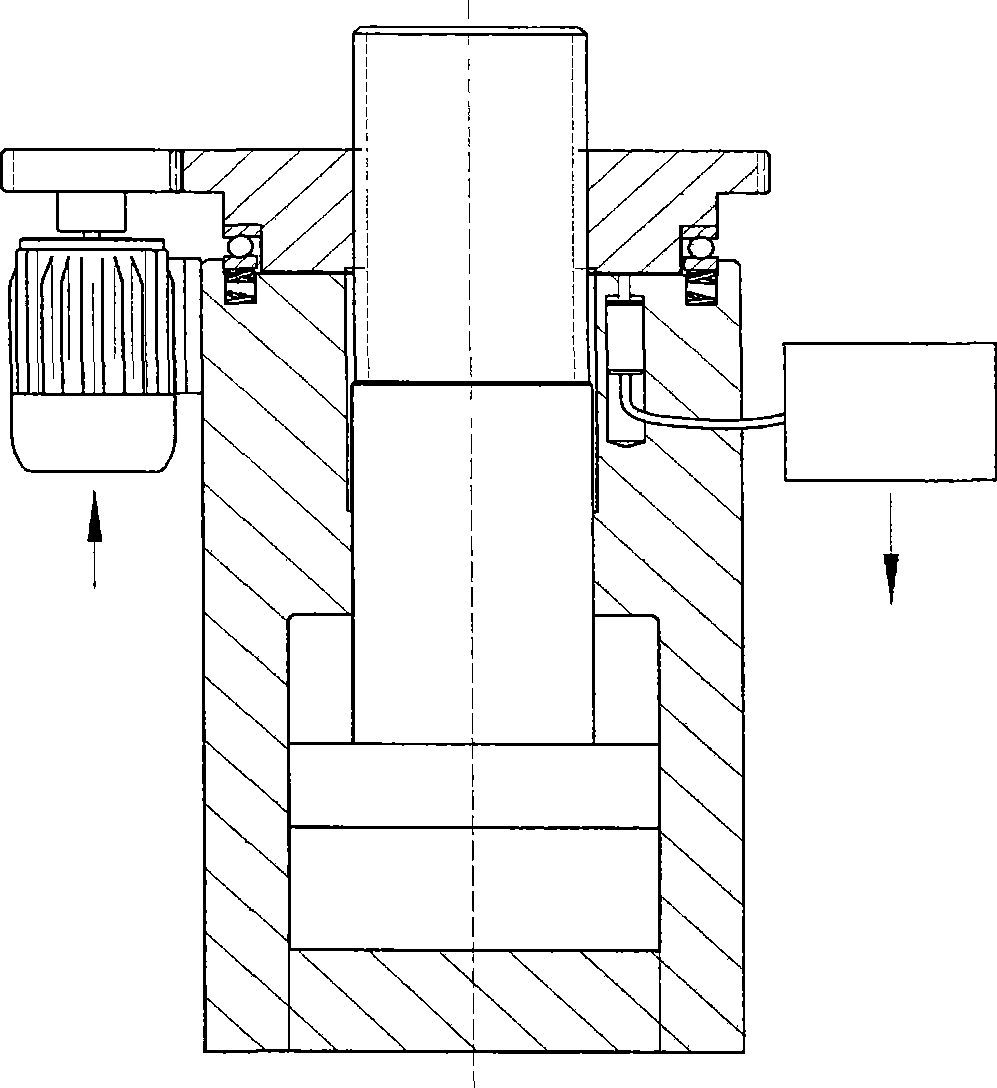

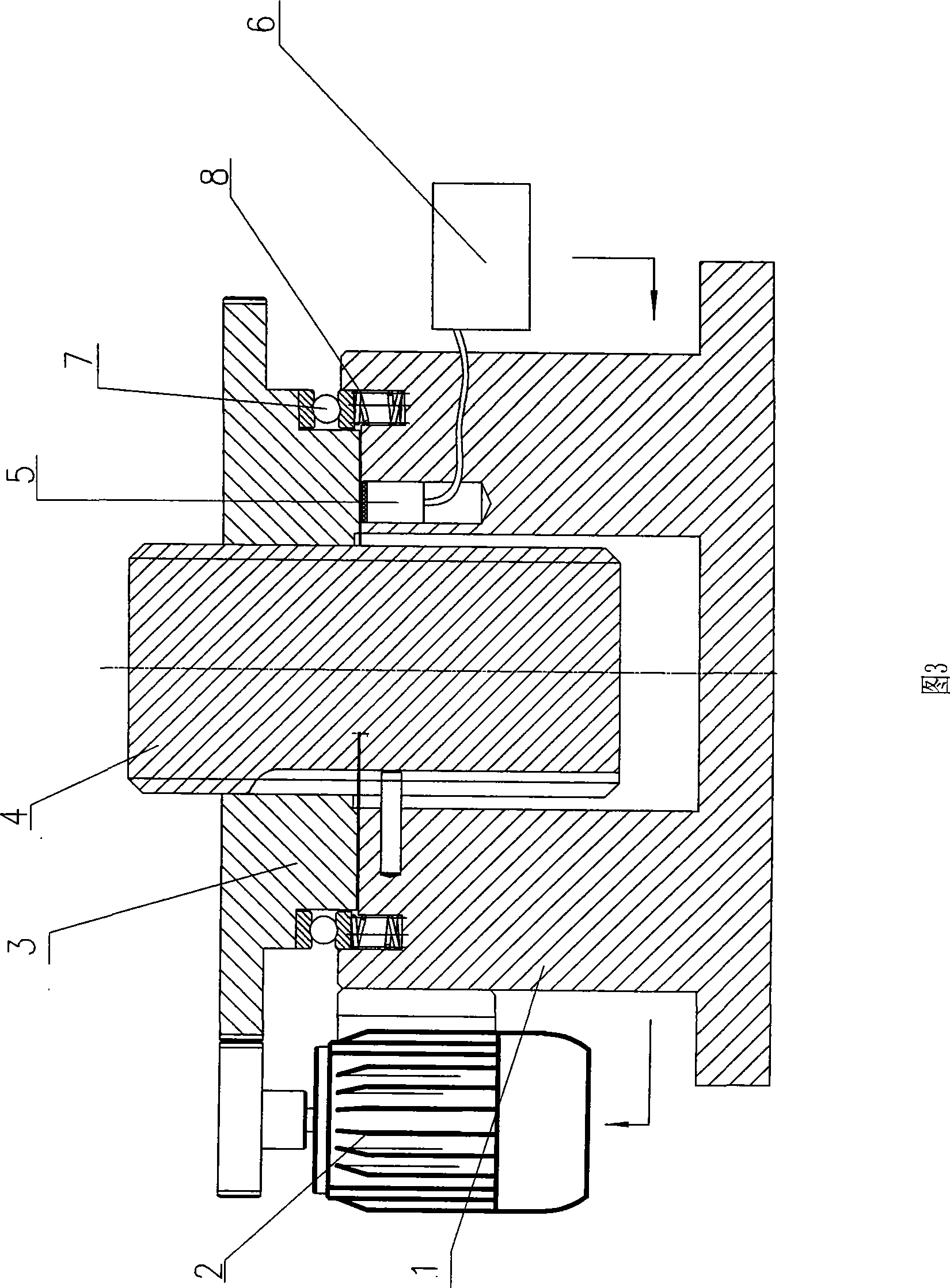

[0014] Such as figure 1 , shown in Fig. 3, is the screw rod follow-up support mechanism of the present invention, and it is made up of several follow-up support screw rods with bearings. It includes a base 1, a servo motor 2, a bearing round nut 3, a heavy-duty screw 4, a micrometer 5, an electronic amplifier 6, a bearing 7 and a spring 8, etc.

[0015] In the present invention, a heavy-duty screw 4 is installed on the base 1, the load-bearing round nut 3 is set on the heavy-duty screw 4, and a bearing 7 is installed between the load-bearing round nut 3 and the base 1 to reduce the distance between the load-bearing round nut 3 and the base 1. the friction between them. A support spring 8 is installed below the bearing 7, so that a gap δ is formed between the heavy-duty round nut 3 and the support 1. The output shaft of the servo motor 2 is equipped ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com