Wellhead sealing body

A sealing body and interface technology, which is applied in sealing/isolation, wellbore/well components, earthwork drilling, etc., can solve pollution and other problems, and achieve the effect of avoiding environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

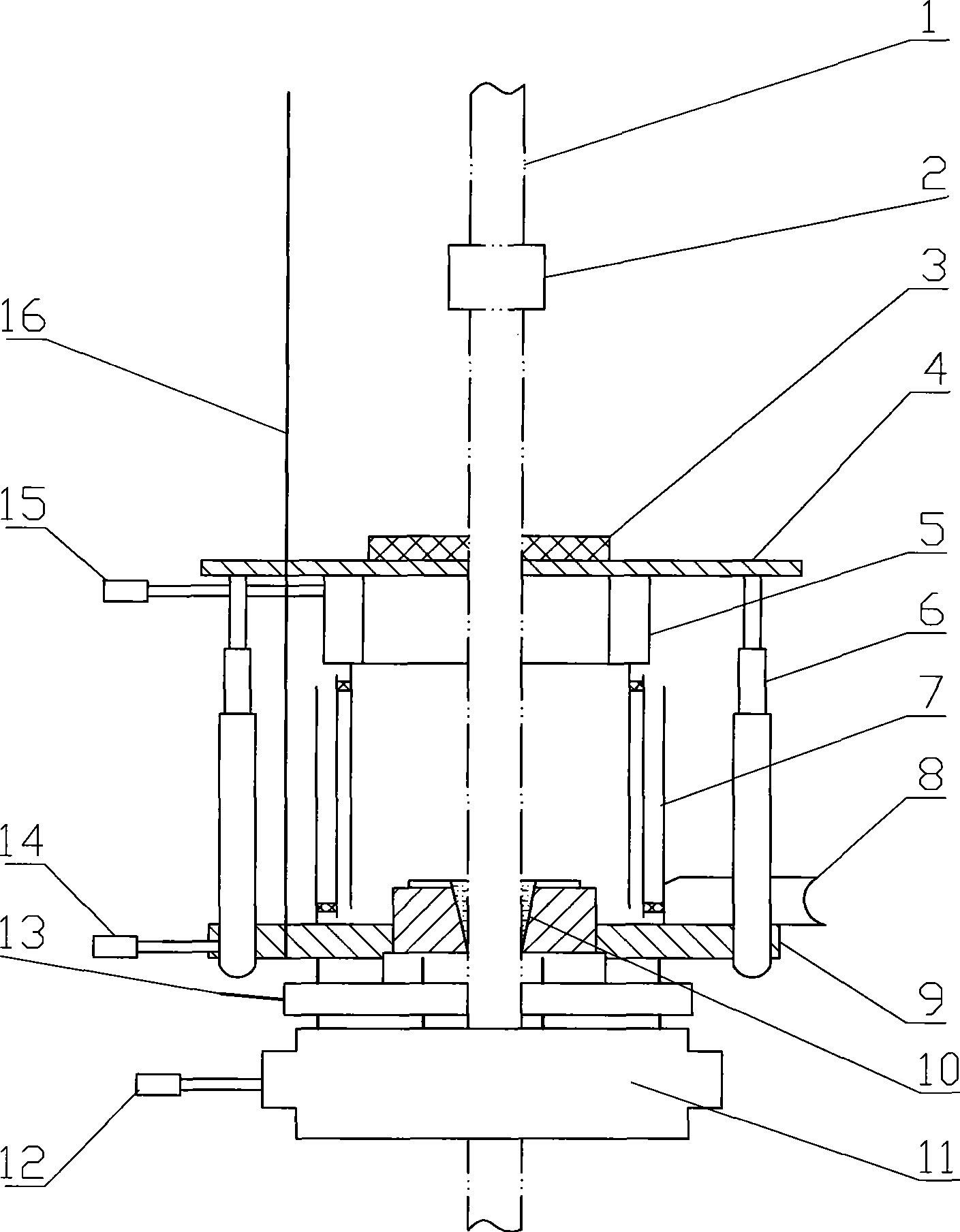

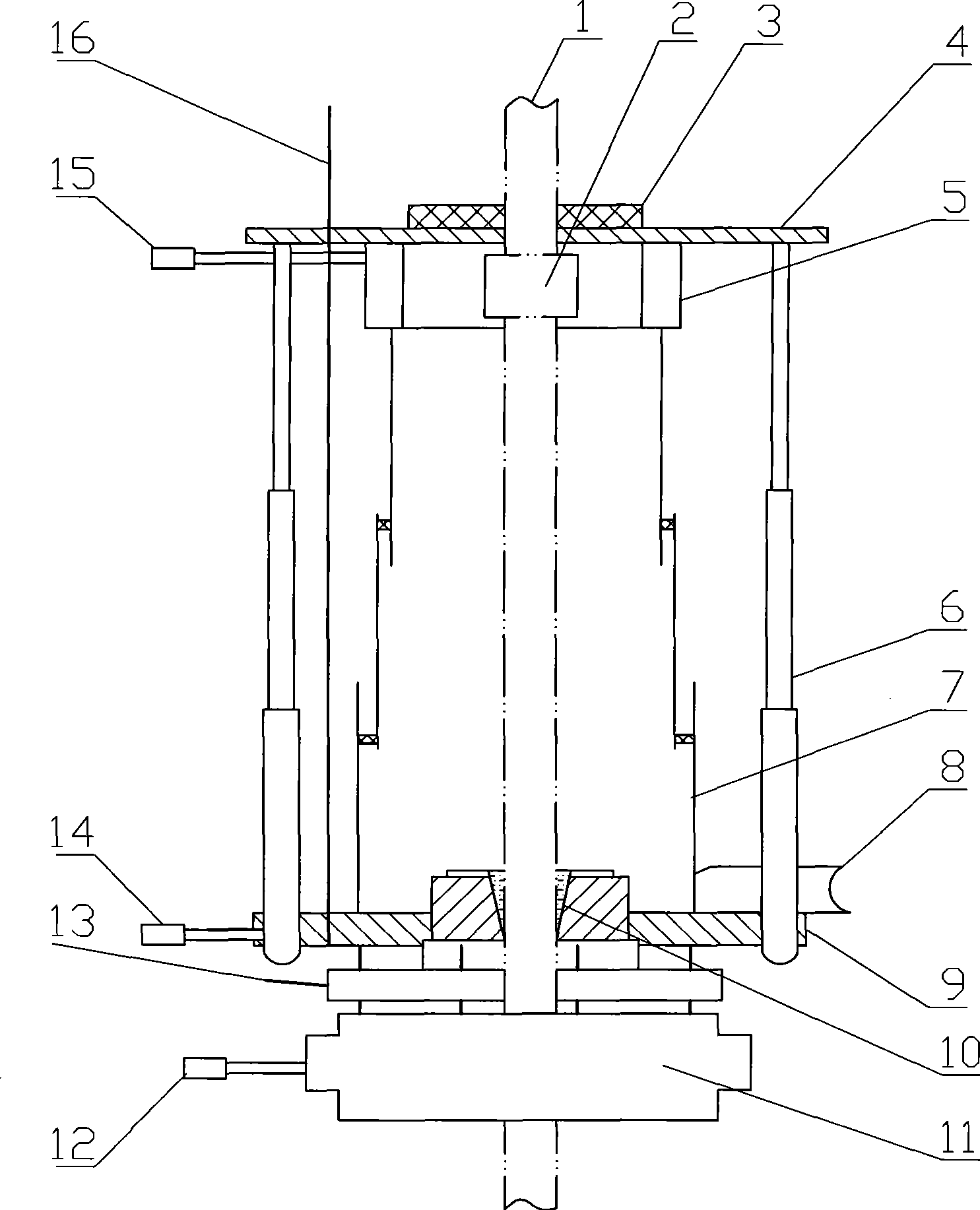

[0012] Such as figure 1 As shown, this specific embodiment includes an oil pipe self-sealing device 3, a fixed backup tong 5, an upper lifting support plate 4, a multi-stage hydraulic lifter 6, a swimming slide 7, a lower lifting plate 9, and a pneumatic safety slip 10 , double ram hydraulic blowout preventer 11 and reference scale 16.

[0013] The upper lifting support plate 4, the multi-stage hydraulic lifter 6, the traveling sliding cylinder 7 and the lower lifting plate 9 form a telescopic oil reservoir. The multi-stage hydraulic lifter 6 is fixed between the upper lifting support plate 4 and the lower lifting plate 9, and the swimming slide 7 includes a plurality of sealed and plugged cylinders or skirt-like soft cylinders, and the bottom of the lower cylinder is provided with There is an oil spill pipe interface 8, and the lower end of the movable slide cylinder 7 is fixed with the lower lifting plate 9, and the upper end of the movable slide cylinder 7 is fixed with th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com