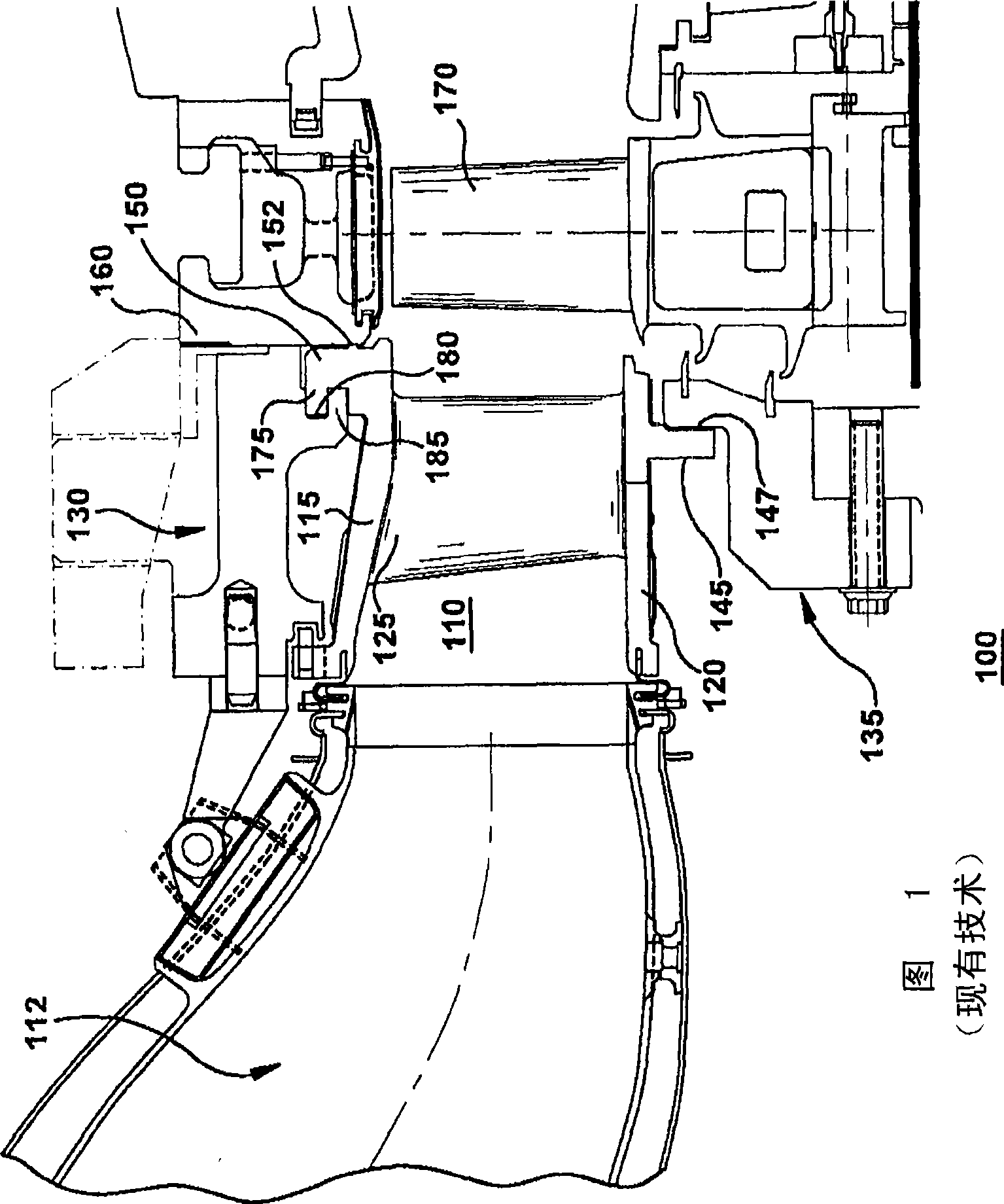

Fully contained retention pin for a turbine nozzle

A turbine nozzle and retaining pin technology, applied in machine/engine, bolt, stator, etc., can solve problems such as increased nozzle structure cost, poor chord hinge seal, poor thermal insulation of retaining ring, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

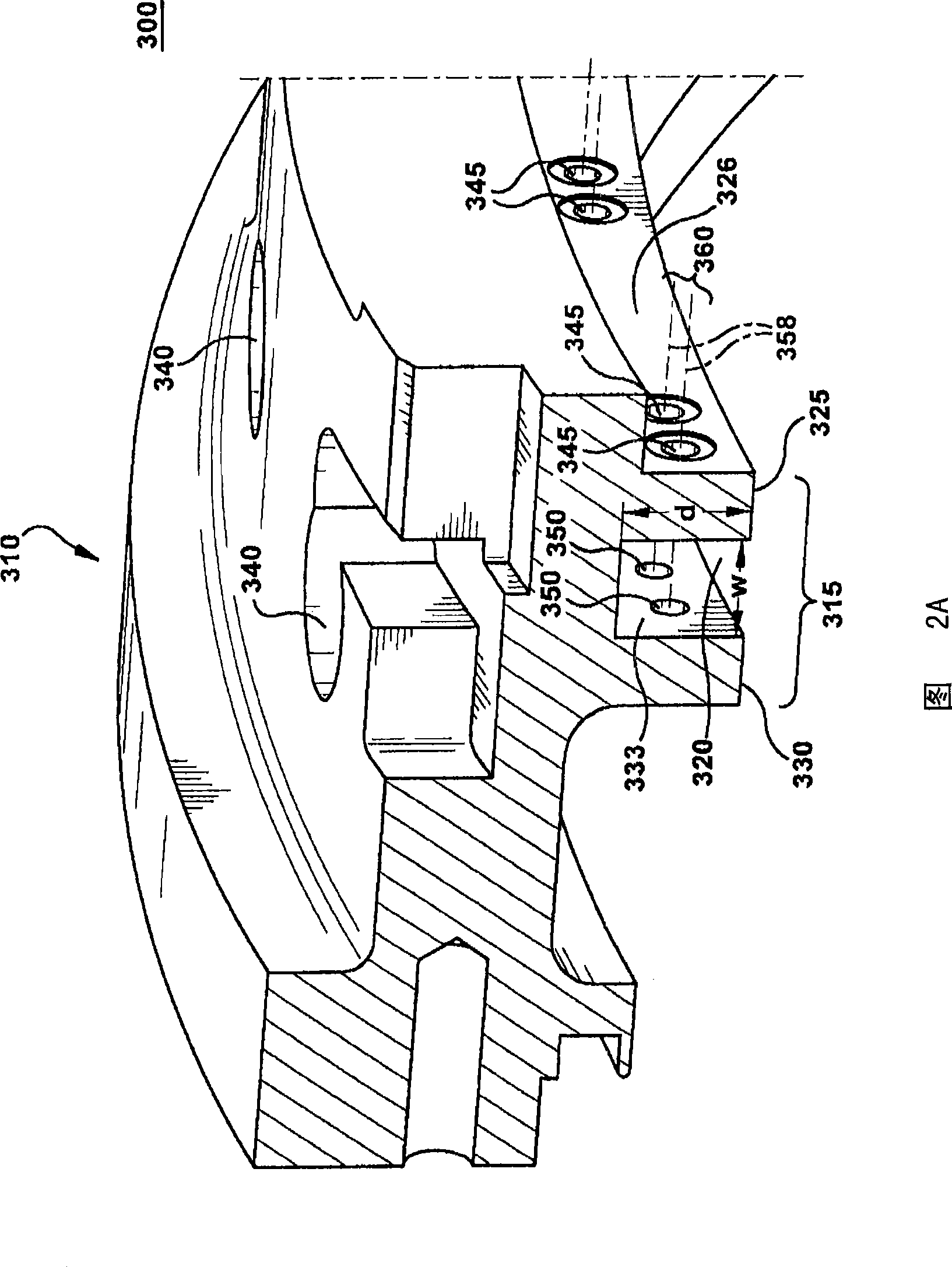

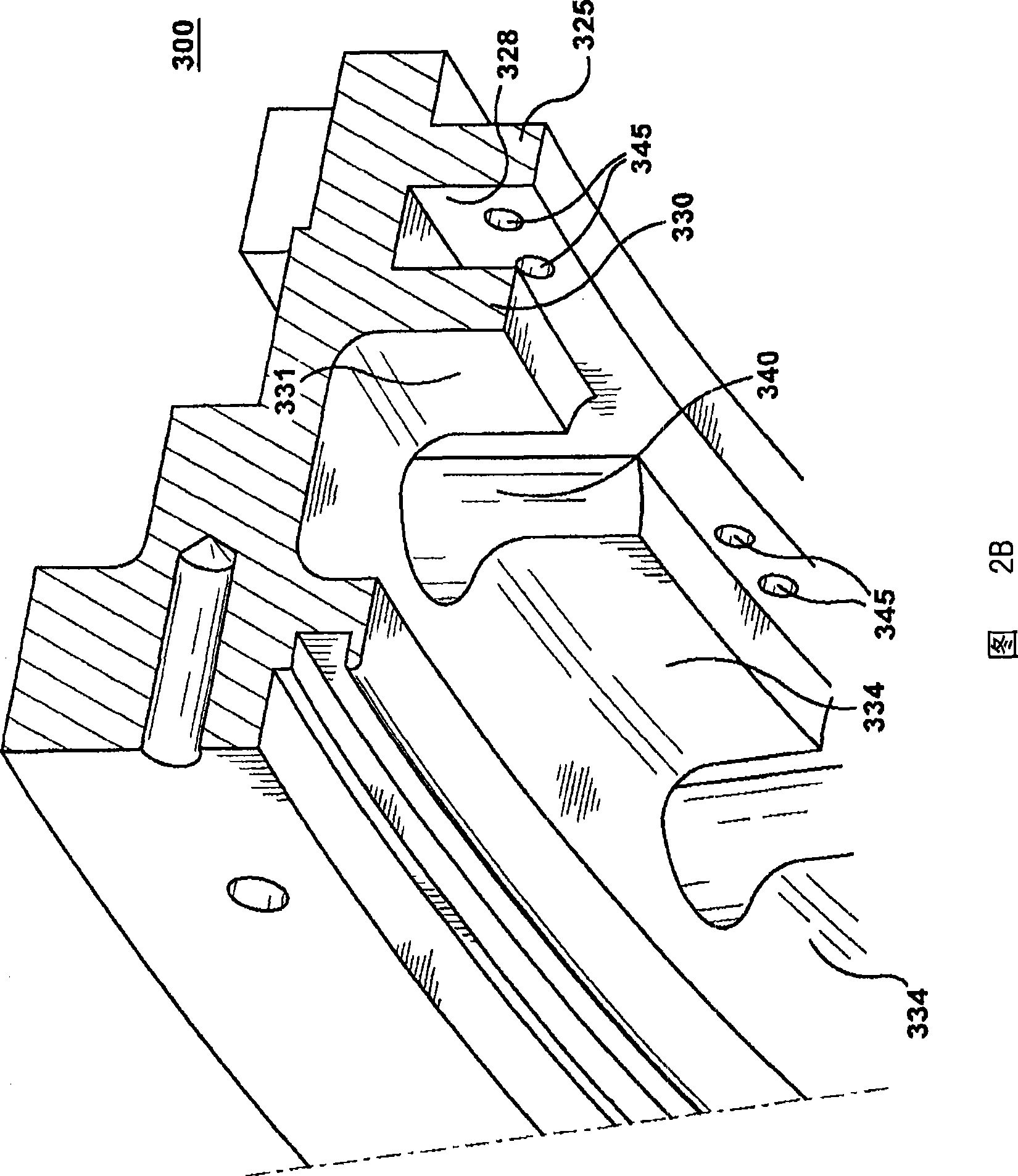

[0109] The following embodiments of the invention have several advantages, including improved nozzle stability, defined nozzle loading and provided retaining ring insulation. The pins are unique in the relative size and retention scheme of the features and are critical to the function of the turbine assembly (2 per nozzle). A pin for each nozzle will fix the radial and circumferential position of the nozzle, yet allow transitional motion. They also keep the nozzle and retaining ring in minimal contact so as to significantly reduce heat conduction from the nozzle to the retaining ring (a source of out-of-round retaining ring). By positioning the nozzles, they will also set the nozzle throat area desired for optimum turbine performance. The axial length of the pin is optimized so that it is impossible for the nozzle to disengage within the assembly due to the pin withdrawing from its normal axial position, and the pin is designed so that the pin will not fail due to low cycle f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com