Optical fiber joint sealing case and sealing method

A fiber optic connector and sealing box technology, applied in the field of optical communication, can solve problems such as complex construction on site, poor operability on site, complex structure, etc., and achieve the effects of reliable sealing method, convenient maintenance and expansion, and simple and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

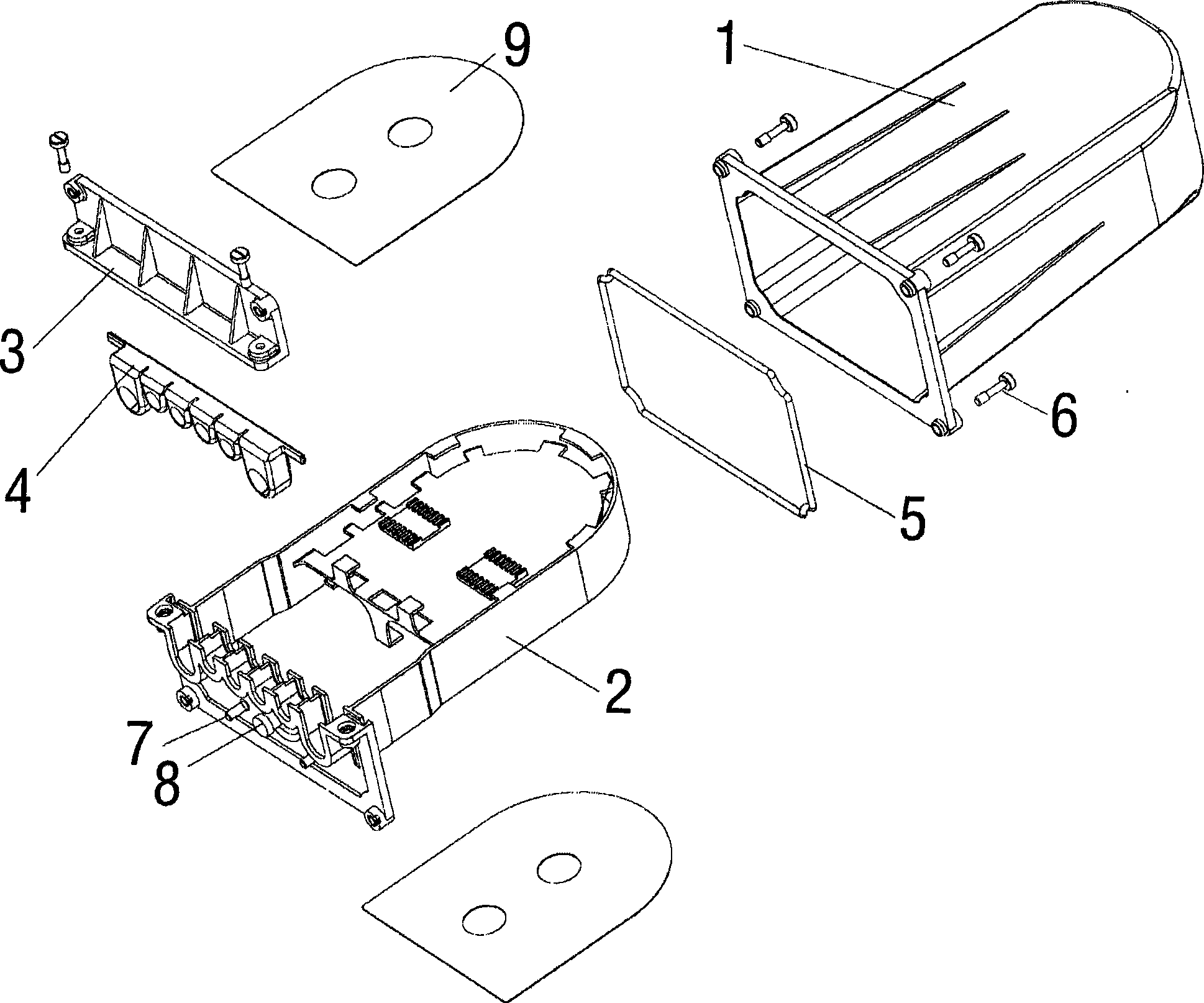

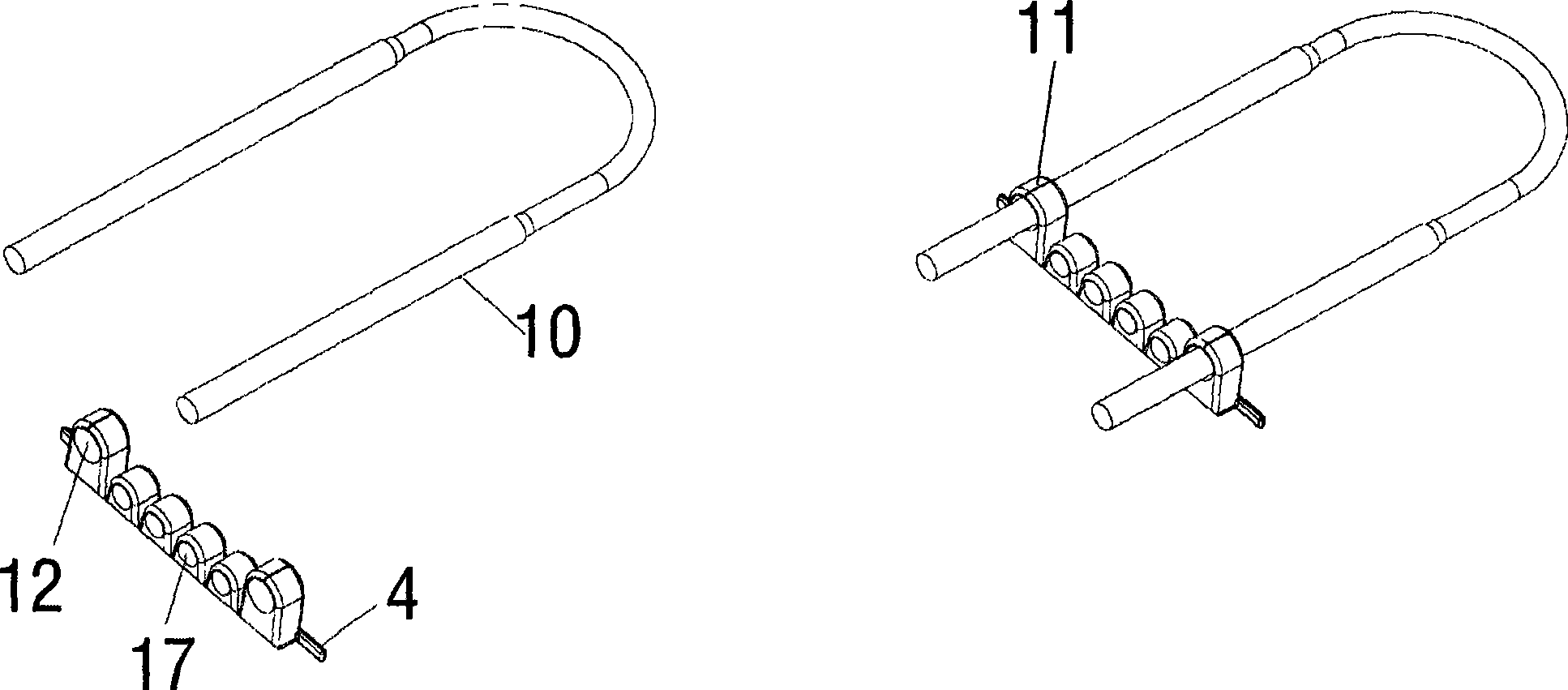

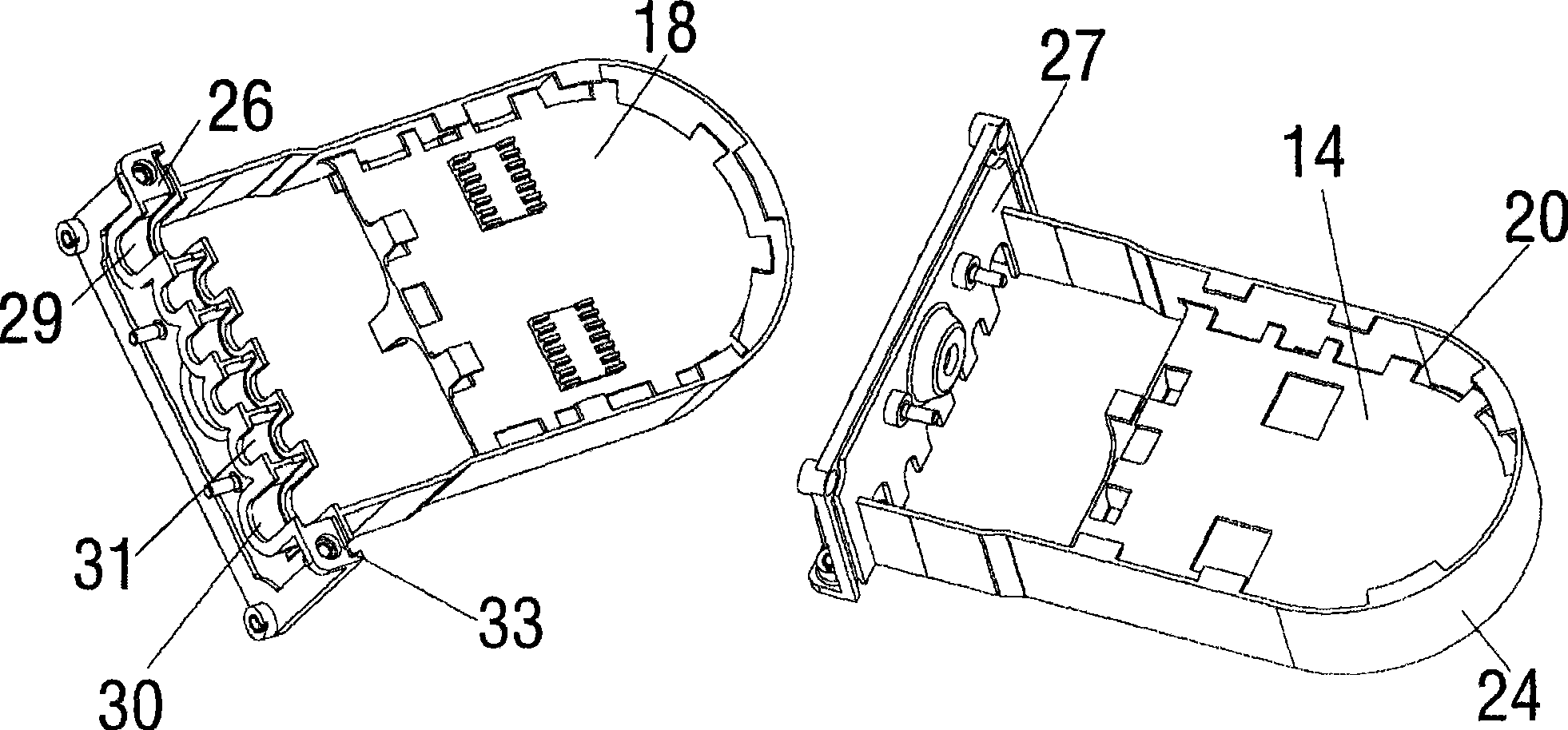

[0052] The optical fiber joint sealing box of the present invention is in the shape of a square cylinder, and adopts a structure with one end closed and one end open, thereby reducing the sealing length to the greatest extent. The square box body is a five-sided sealed cavity, the splice tray is L-shaped, the long end is the splice tray, the short end is combined with the pressure plate to form a sealing surface, and the optical fiber enters and exits through the joint.

[0053] After the optical fiber is welded and fixed in the open space, it is pushed into the square box as a whole, and the locking screw can be fixed and joined.

[0054] The main optical cable with a continuous length is squeezed into the through hole of the seal through the gap of the integral seal, and then put into the closed cavity as a whole, the pressure plate is pressed in from above, the seal is in the closed cavity, and the material is only under pressure. The through hole can be extruded radially, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com