A drum sealing device of a drum type chip removal machine, a drum, and a drum chip removal machine

A technology of sealing device and chip removal machine, which is applied in the direction of engine sealing, mechanical equipment, engine components, etc., can solve problems such as sealing failure, achieve reliable sealing device, avoid frequent replacement of sealing parts, and solve the effect of sealing failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

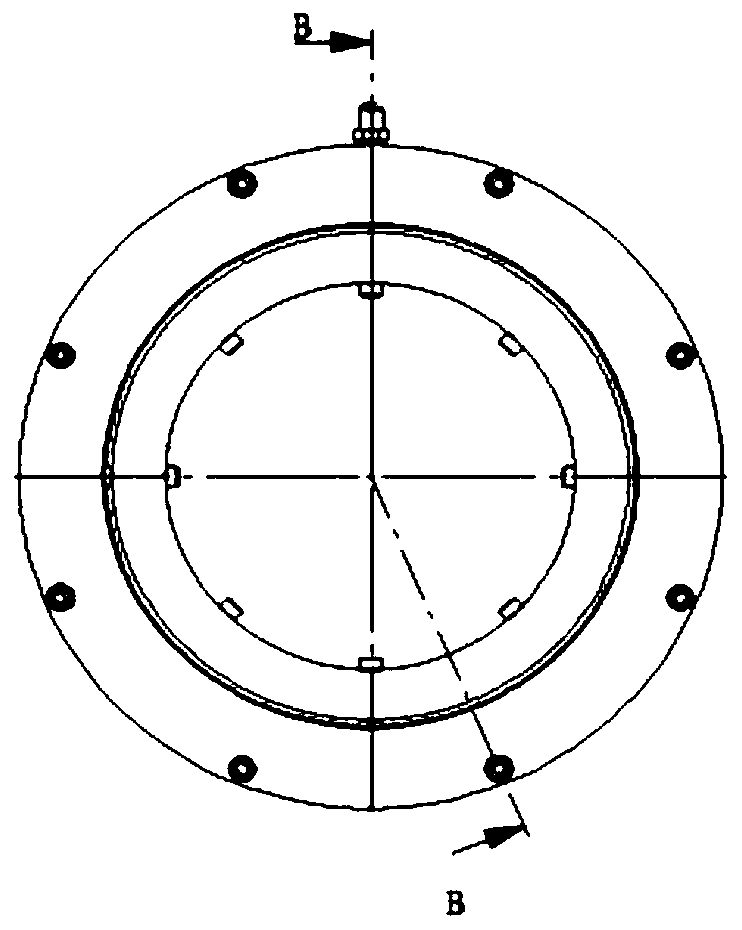

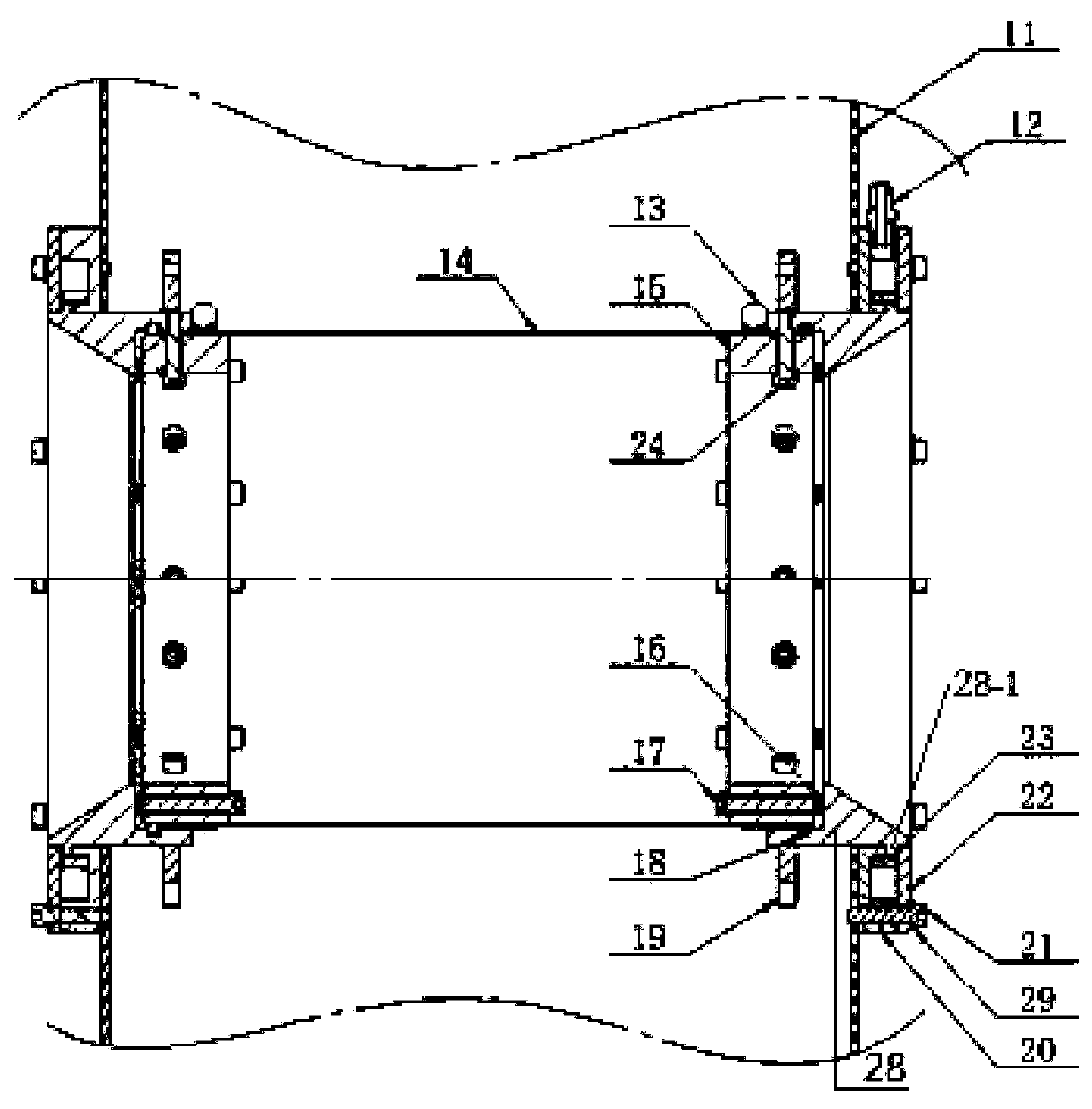

[0025] Such as figure 1 with figure 2 As shown, a drum sealing device of a drum type chip removal machine, the drum sealing device is symmetrically installed on the two outer sides of the drum, and the structure includes: an inner ring 15 located on the outer side of the drum, and a filter fixed on the outer wall of the inner ring through a throat hoop 13 The net 14, which constitutes the main structure of the drum, is used to filter the cutting fluid. The moving ring 28 fixedly connected to the inner ring through the second bolt 24 is assembled with the main side wall 11 of the chip removal machine. The outer wall of the moving ring is located at the chip removal A convex ring 28-1 is provided between the side wall of the main body and the front end of the moving ring, and the inner wall is composed of a cylindrical hole and a conical hole, wherein the inner wall of the cylindrical hole is in contact with the outer wall of the inner ring, and the inner diameter of the conica...

Embodiment 2

[0028] Such as figure 1 with figure 2 As shown, the drum of a drum chip removal machine is composed of the drum sealing device in Embodiment 1. The outer wall of the moving ring 28 of the drum sealing device is provided with a sprocket 19, and the sprocket 19 is located on the side wall of the main body of the chip removal machine. The inner side, close to the end of the moving ring, is fixed to the filter screen 14 on the outer wall of the inner ring through the throat hoop 13, which constitutes the main structure of the drum and is used to filter the cutting fluid.

Embodiment 3

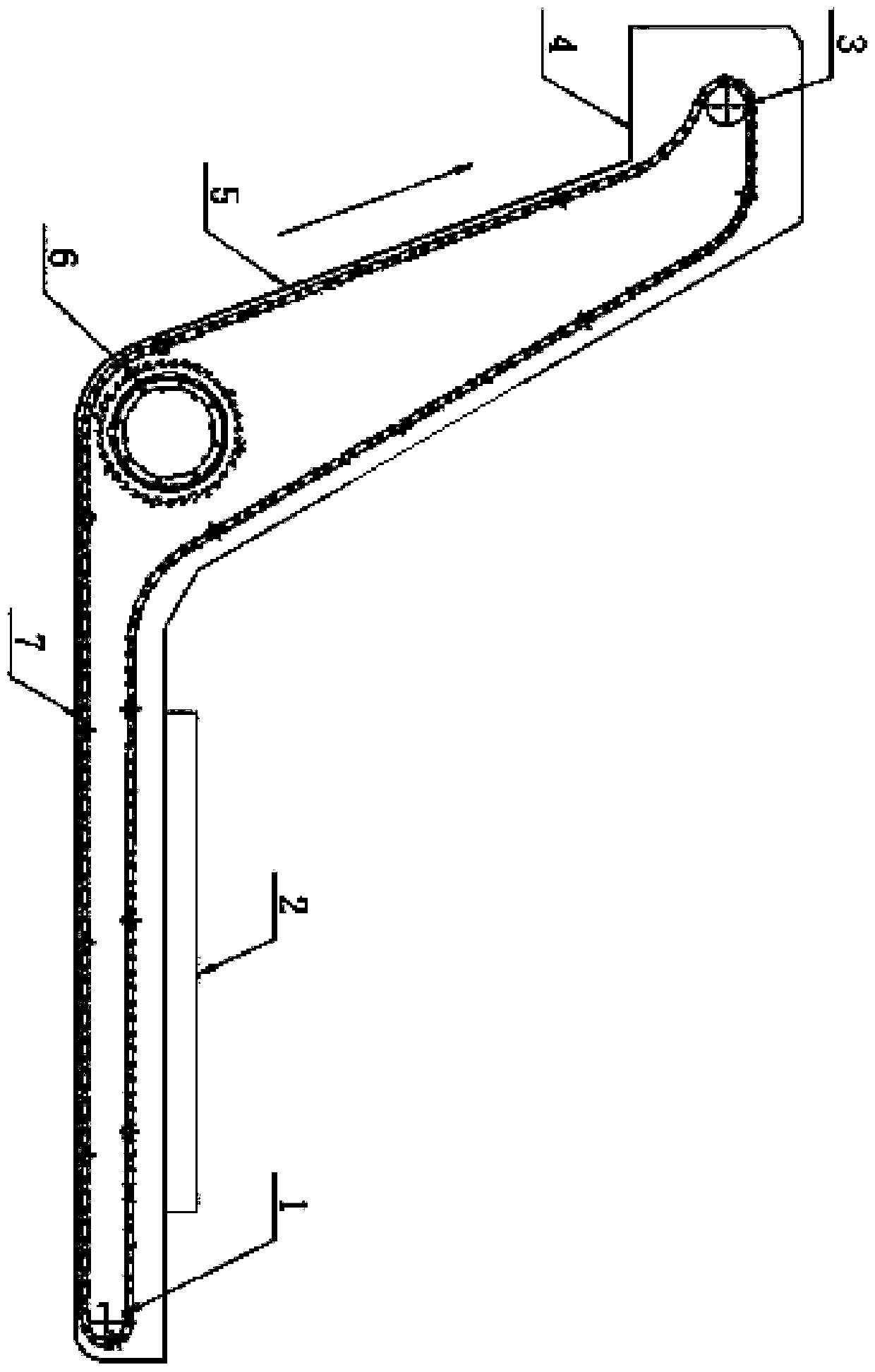

[0030] Such as image 3 with Figure 4As shown, a drum chip removal machine, the structure includes: the chip removal machine main body 5, which is divided into a horizontal section and an inclined rising section, and the chip removal port 2 installed above the horizontal section of the chip removal machine main body is used to remove the chips containing chips The liquid is discharged into the chip conveyor, the tail rotary device 1 is installed at the tail of the horizontal section of the main body of the chip conveyor, the head rotary device 3 is installed at the end of the inclined upward section of the chip conveyor body, and the head rotary device 3 and the tail rotary device The scraper chain belt 7 connected to the device 1, the scraper chain belt 7 is a closed structure, which can be driven around the head slewing device and the tail slewing device, and the roller device 6 is installed at the lower end of the intersection of the horizontal section and the inclined ris...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com