Method and unit for the extremely fine dispersal and discharge of an irritant or warfare agent

A technology of stimulants and combat agents, applied in the direction of injection devices, liquid injection devices, gas injection devices, etc., can solve the problem of reducing the discharge energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

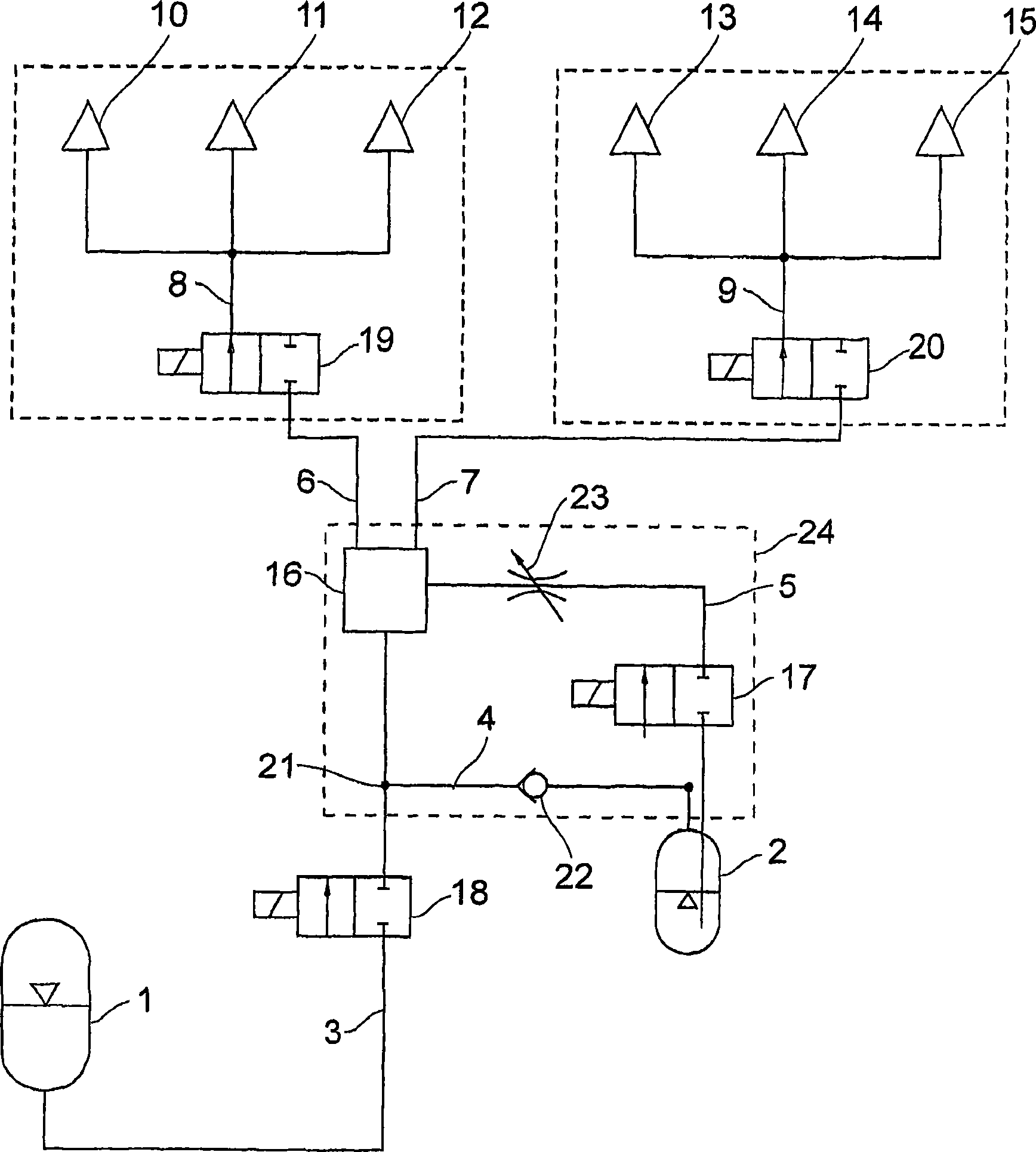

[0027] Will compare with figure 1 Preferred embodiments of the present invention will be described in detail.

[0028] figure 1 The shown block diagram shows a stimulating agent or combat agent distribution device, wherein the stimulating agent or combat agent is delivered from the storage container 2 to a plurality of injectors via a branched pipeline system 3, 4, 5, 6, 7, 8, 9 Nozzles 10 to 15. In this exemplary embodiment, two sets of injection nozzles 10 , 11 , 12 and 13 , 14 , 15 are provided. These groups can be activated selectively via the 2 / 2-way valves 19 , 20 .

[0029] Through the 2 / 2 reversing valve 18 , the liquid booster gas is pressed from the liquefied gas bottle 1 into the pipeline 3 and delivered to the mixer 16 . At the inlet of the mixer 16 , at a branch point 21 , a part of the booster gas is branched off from the line 3 via the line 4 with a non-return valve 22 for the pressure build-up in the stimulant container 2 . The non-return valve 22 serves t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com