Method for fabrication of a structural element for aeronautical construction including a differential work hardening

一种结构元件、热加工的技术,应用在航空工程领域,能够解决无法转化等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0087] In this example, a plate made of alloy AA2023 with a thickness of 25 mm and spatially variable properties was obtained.

[0088] By hot-rolling the rolled slab, a plate material with a length of 30 meters, a width of 2.5 meters, and a thickness of 28.2 mm was manufactured.

[0089]The composition of the alloy used is shown in Table 1 below:

[0090] Table 1: Composition of alloy AA2023 rolled slabs (mass%)

[0091] Si Fe Cu Mg Ti Zr sc 0,06 0,07 3,81 1,36 0,024 0,11 0,03

[0092] The rolled slab was homogenized at 500°C for 12 hours. The hot rolling inlet temperature is 460°C.

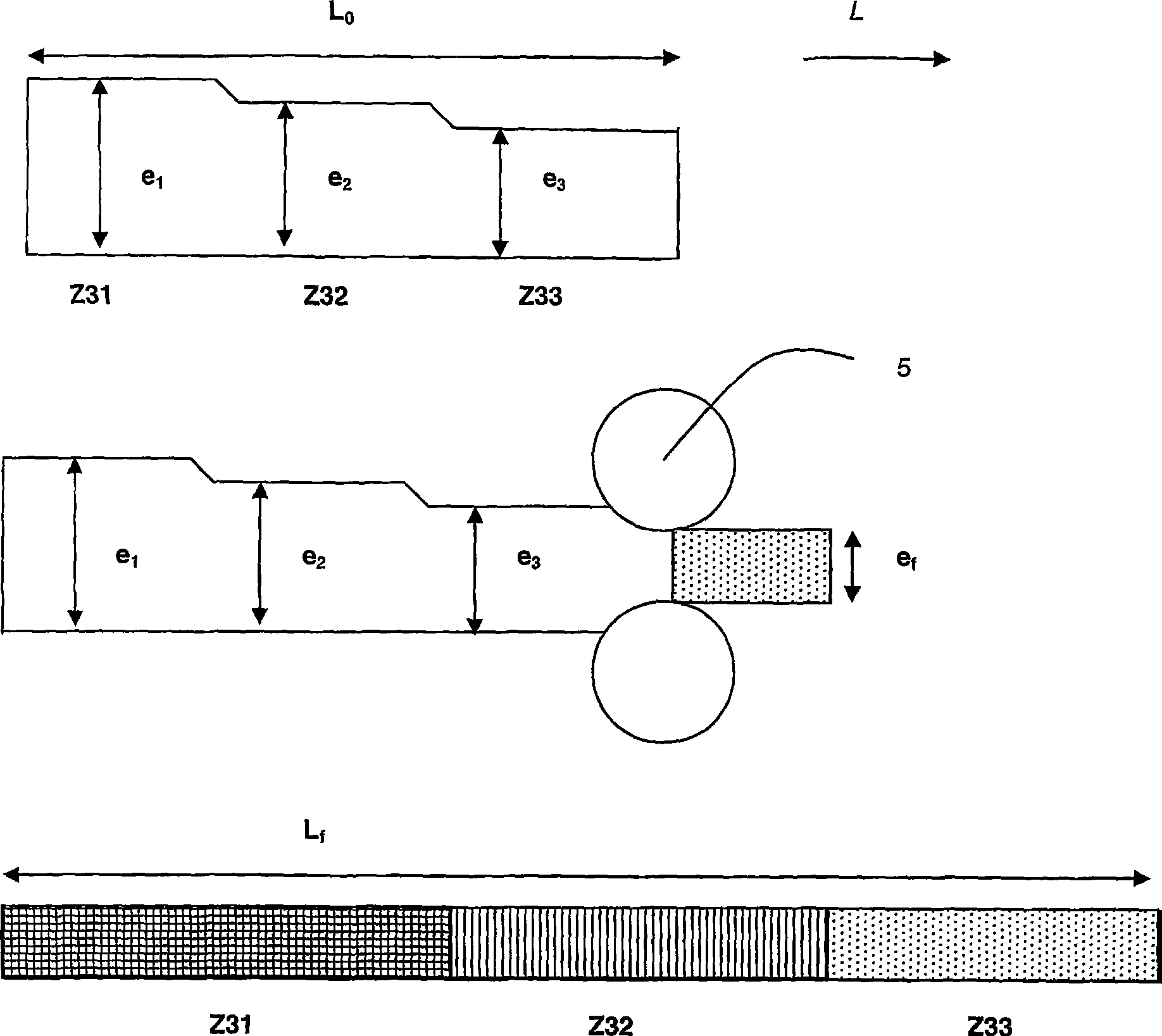

[0093] After hot rolling, the plates are image 3 Machining is carried out as shown to obtain three zones Z31, Z32 and Z33 with a length equal to 10 meters and a thickness as follows:

[0094] Zone Z31: 28.1mm

[0095] Zone Z32: 26.3mm

[0096] Zone Z33: 25.5mm

[0097] The plate was then solution treated and quenched at 500°C.

[0098] The sheet is th...

Embodiment 2

[0108] In this example, a plate made of alloy AA2024A with a thickness of 15 mm and spatially variable properties was obtained.

[0109] By hot-rolling the rolled slab, a plate with a length of 30 meters, a width of 2.5 meters, and a thickness of 16.8 mm was manufactured.

[0110] The composition of the alloy used is shown in Table 4 below:

[0111] Table 4: Composition of alloy AA2024A rolled slabs (mass%)

[0112] Si Fe Cu mn Mg Ti 0,04 0,07 3,96 0,38 1,29 0,013

[0113] The rolled slab is homogenized and then hot rolled.

[0114] After hot rolling, the plates are image 3 Machining is carried out as shown to obtain three zones Z31, Z32 and Z33 with a length equal to 10 meters and a thickness as follows:

[0115] Zone Z31: 16.7mm

[0116] Zone Z32: 15.9mm

[0117] Zone Z33: 15.3mm

[0118] The plate was then solution treated and quenched at 500°C.

[0119] The sheet is then cold rolled to obtain a substantially constant thickness of 1...

Embodiment 3

[0129] In this example, a profile made of alloy AA2027 with a section of 170×45 mm and with spatially variable properties was obtained.

[0130] A profile with a length of 15 meters and a section of 170×45 mm was manufactured by hot extrusion of the drawn billet.

[0131] The composition of the alloy used is shown in Table 7 below:

[0132] Table 7: Composition of alloy AA2027 rolled slabs (mass%)

[0133] Si Fe Cu mn Mg Zn Ti Zr 0,05 0,11 4,2 0,6 1,3 0,06 0,02 0,11

[0134] The drawn billet was homogenized at 490°C and then hot extruded.

[0135] After drawing, the profile is solution treated and quenched at 500°C.

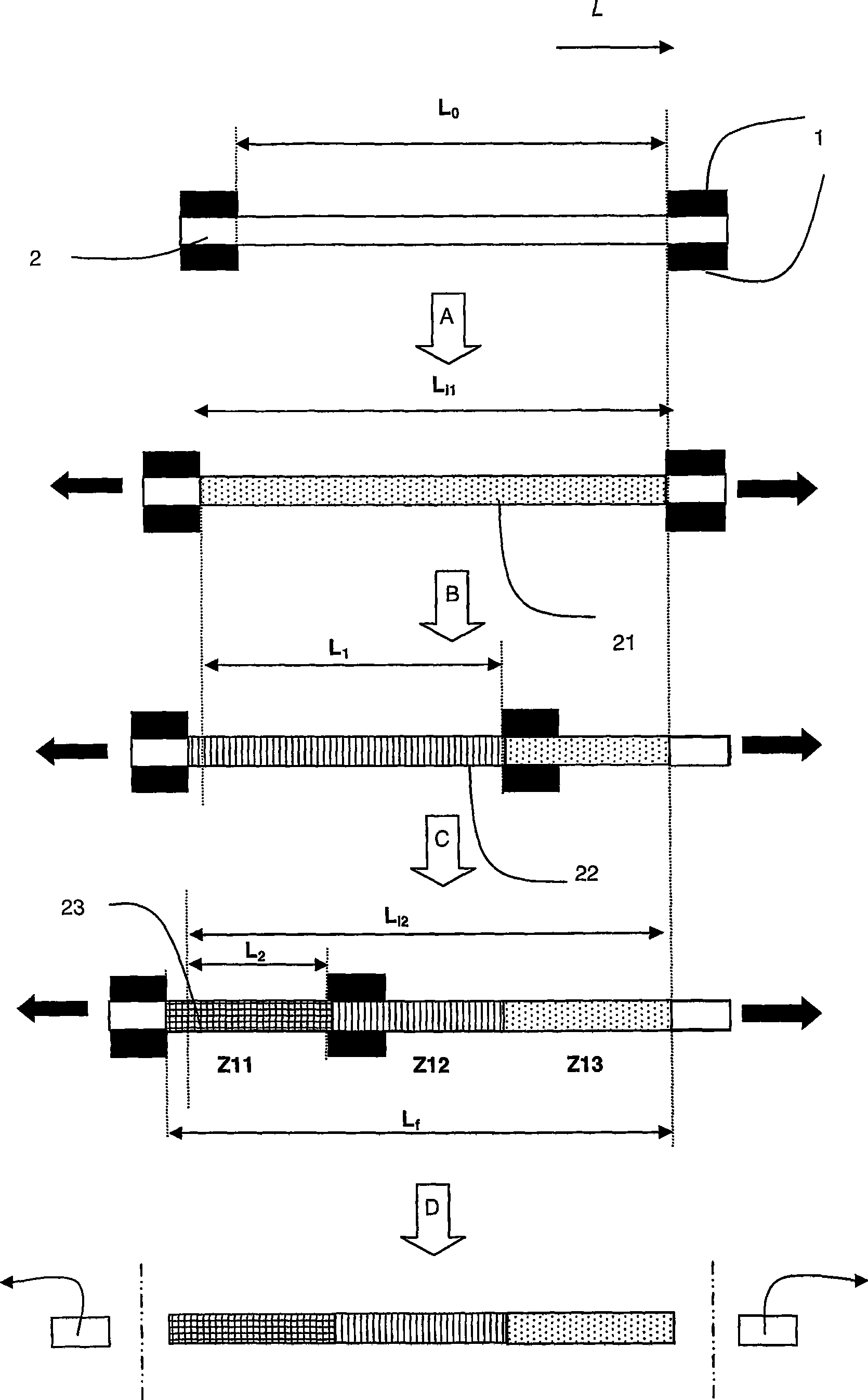

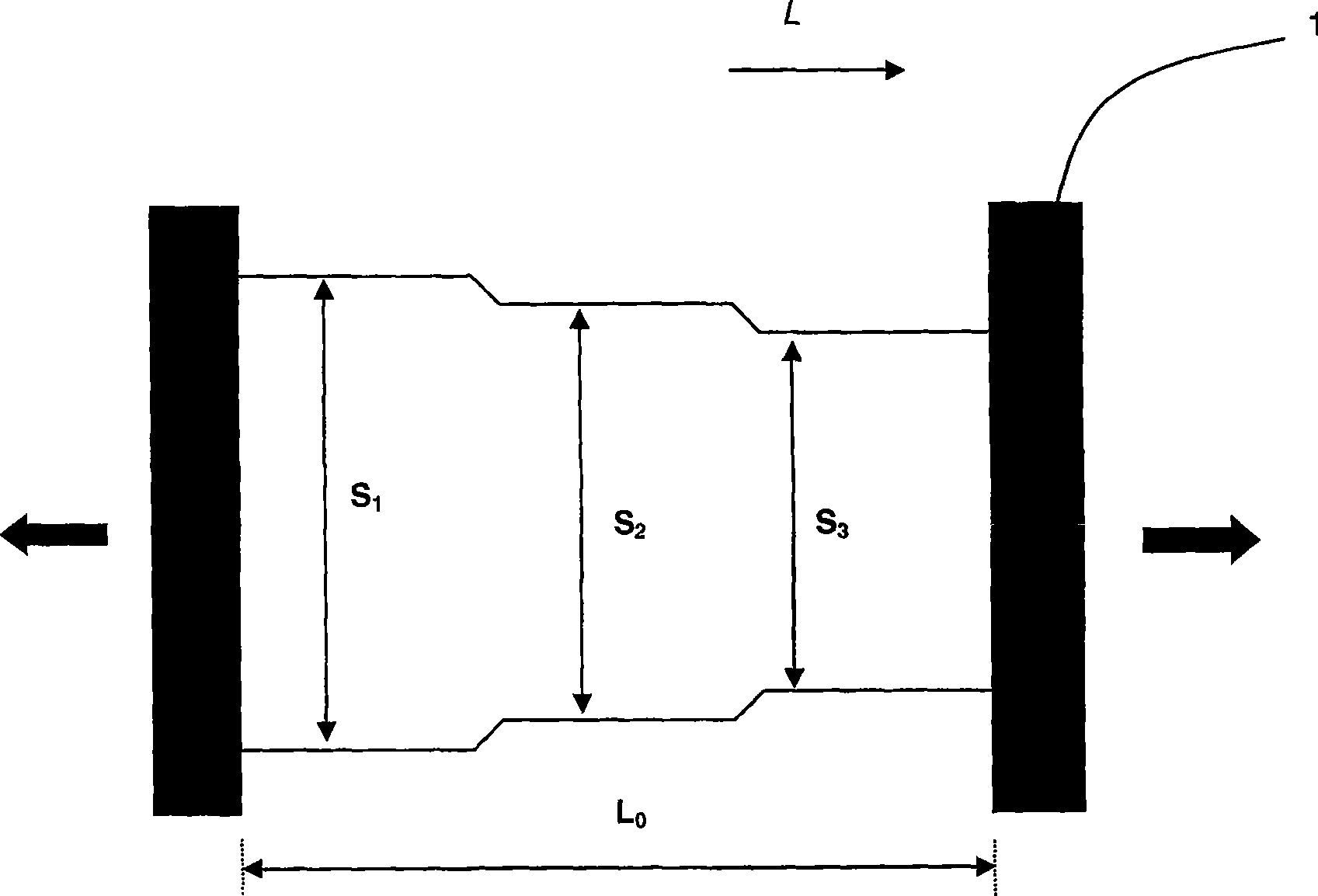

[0136] A first step of controlled stretching was then performed to permanently elongate it by 2.8%. Then make one claw of the stretching table such as figure 1 Move as shown so that one end of the profile protrudes beyond the claw. A second stretching step was then carried out on the two thirds of the profile between th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com