Take-off device for ornithopter

A technology of orthopter and airport runway, which is applied in the field of aeronautical engineering, can solve the problems of orthopter flight stability, surrounding environmental pollution, large fuel consumption, etc., to ensure vacuum heat insulation effect, ensure reasonable support, and reduce wear and tear small effect

Pending Publication Date: 2019-06-18

TAIYUAN UNIVERSITY OF SCIENCE AND TECHNOLOGY

View PDF8 Cites 1 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0002] At present, orptopters take off at home and abroad all adopt orptopter airport runways, which mainly have the following disadvantages: Due to the direct take-off of the orthopter, a large amount of fuel will be consumed and the surrounding environment will be polluted; When the orthopter takes off, the initial speed of the orthopter is lower than that of the fixed-wing aircraft. The crosswind at the airport will easily cause the flight stability of the orthopter, making it difficult to take off.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 2

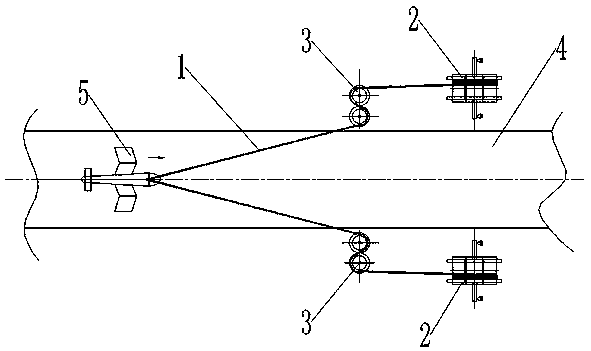

[0030] Since the orthopter 5 often takes off in two directions according to the wind direction, when the orthopter 5 takes off in the opposite direction, adopt the following method: Figure 4 The drag method shown.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

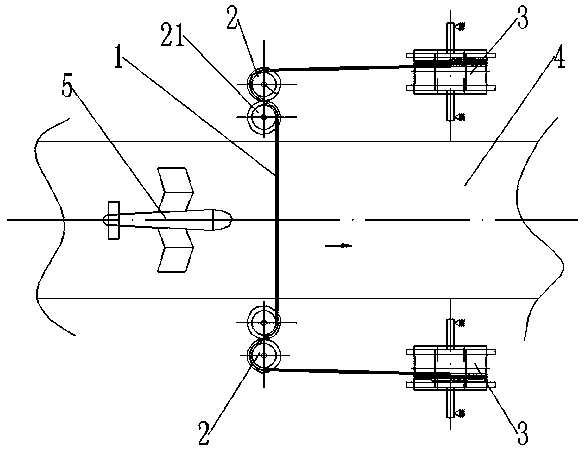

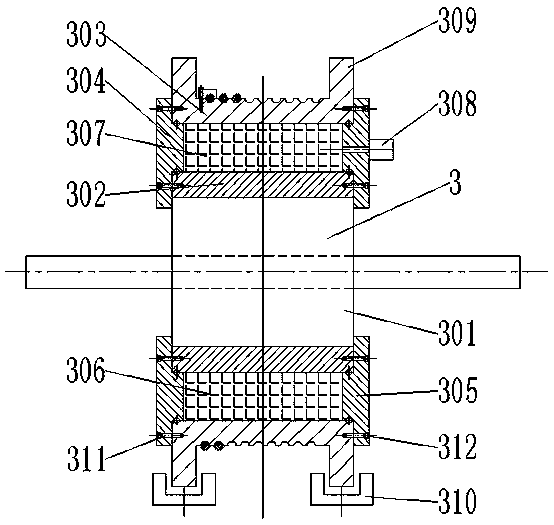

The invention belongs to the technical field of aviation engineering, and particularly discloses a take-off device for an ornithopter. The take-off device comprises a transverse cable, two pulley components, and two drum components driven by outer rotor motors; the two pulley components and the two drum components are arranged in symmetry relative an airport runway; the transverse cable is sequentially wound around one drum component, the fixed pulley component on the same side, the fixed pulley component on the opposite side and the other drum component on the opposite side. The transverse cable crosses the airport runway, and the drum components are driven by the outer rotor motors. During take-off, the transverse cable is pulled by a towing vehicle to be hung on a padlock mechanism at the front end of the ornithopter, an ornithopter engine and the outer rotor motors are cooperatively started to assist the take-off, and the outer rotor motors help provide the initial speed of the ornithopter, so that the stability of the ornithopter is enhanced, the sliding distance of the ornithopter is shortened, and an ornithopter runway is shortened; by the design of the pulley components, the take-off direction can be selected according to the actual wind direction; through electric power assisted dragging, the fuel consumption is reduced, and the surrounding environmental pollution of an airport is reduced.

Description

technical field [0001] The invention belongs to the technical field of aeronautical engineering, and in particular relates to an airfield power-assisted take-off device for a flapping wing aircraft. Background technique [0002] At present, orptopters take off at home and abroad all adopt orptopter airport runways, which mainly have the following disadvantages: Due to the direct take-off of the orthopter, a large amount of fuel will be consumed and the surrounding environment will be polluted; When the orthopter takes off, the initial speed of the orthopter is lower than that of the fixed-wing aircraft. The crosswind at the airport will easily cause the flight stability of the orthopter, making it difficult to take off. Contents of the invention [0003] In order to solve the technical problems existing in the prior art, the present invention provides an airport-assisted take-off device for a flapper aircraft driven by an external rotor motor, which can reduce fuel cons...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B64F1/04B64C33/00

CPCY02T50/80

Inventor 李昕涛

Owner TAIYUAN UNIVERSITY OF SCIENCE AND TECHNOLOGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com