Weaving loom with side-by-side frames, method of weaving using such a loom and preforms thus woven

A braiding machine and frame technology, applied in the field of braiding machines, can solve the problems of time-consuming and complex

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

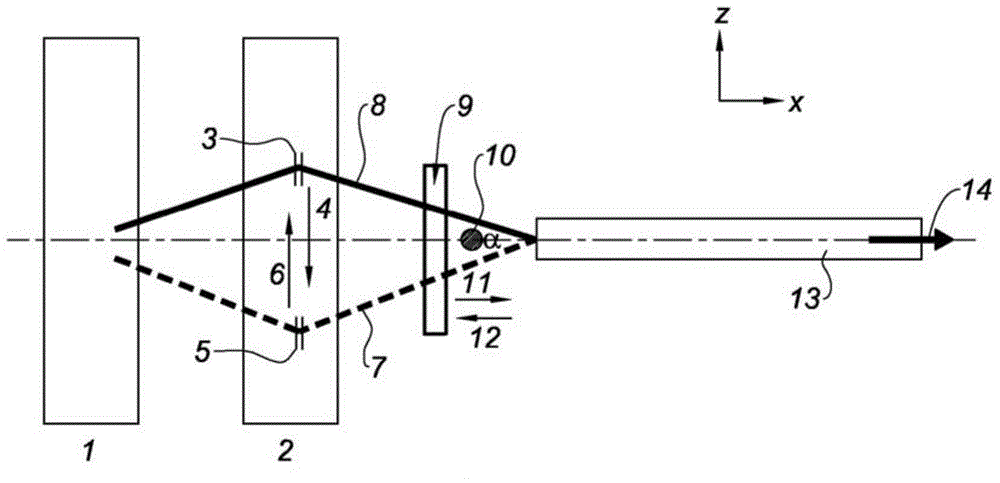

[0021] as attached figure 1 Shown schematically is a prior art knitting machine.

[0022] From left to right in the drawing, the knitting machine includes a covered yarn supply system 1 and a covered yarn sorting system 2. The covered yarn sorting system 2 includes a heald bearing hole 3, and the heddle is movably installed on the frame Placed one by one inside and driven vertically, it also includes a beating reed 9 and a weft yarn insertion system 10, such as a shuttle type weft yarn insertion system. The fabric is a braid 13 driven by a feed system 14 which applies a controllable tension to the covering yarn 8 which enters from the supply system 1 and exits from the feed system 14 .

[0023] Said beating reeds 9 extend between the covered yarns at the frame exit of the ordering system 2 and the teeth of each beating reed are used to push the weft yarn 10 against the fabric which moves back and forth 11 in reciprocating , 12 weaves.

[0024] Synchronized with the movement...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com