Electroplating device and method

An electrolytic coating and coating technology, applied in the field of electrolytic coating devices and methods, can solve problems such as being unable to be used for coating, long devices, etc., and achieve the effect of small intervals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

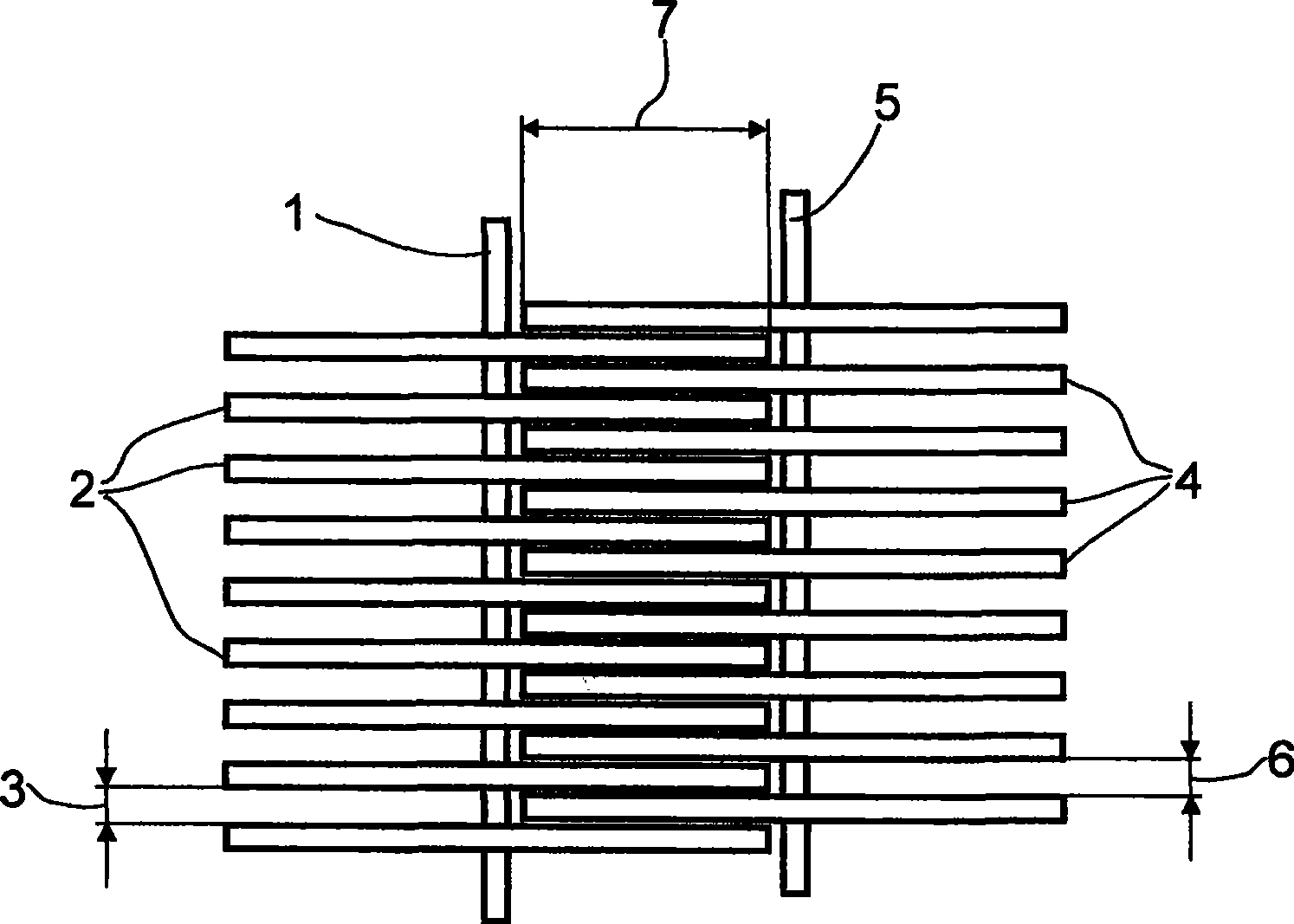

[0060] figure 1 A top view of a device designed according to the invention is shown. A certain number of first disks 2 are arranged on the first shaft 1 . The disks 2 are mounted on the shaft 1 at intervals 3, respectively. The space 3 is chosen such that the disc 4 fastened on the second shaft 5 can engage therein. The spacing 6 of the second disks 4 is chosen such that the first disk 2 can engage between two second disks 4 respectively.

[0061] exist figure 1 In the illustrated embodiment, the first disc 2 mounted on the first shaft 1 and the second disc 4 mounted on the second shaft 5 each have the same width (thickness). However, discs with different widths can also be provided. In this case, disks of equal width may be arranged on one shaft, respectively, and disks of a different width from those on the first shaft are arranged on a second shaft, or disks of different widths may be mounted on one shaft. When discs of different widths are mounted on one shaft, the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com