High-content chlorpyrifos microcapsule suspension agent and production method

A technology of microcapsule suspending agent and chlorpyrifos, which is applied in the fields of botanical equipment and methods, biocides, animal repellents, etc., can solve the problems of adverse health effects of users, waste of industrial resources, pollution of the environment, etc., and the process is easy to control. , the effect of reducing toxicity and reducing acute toxicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

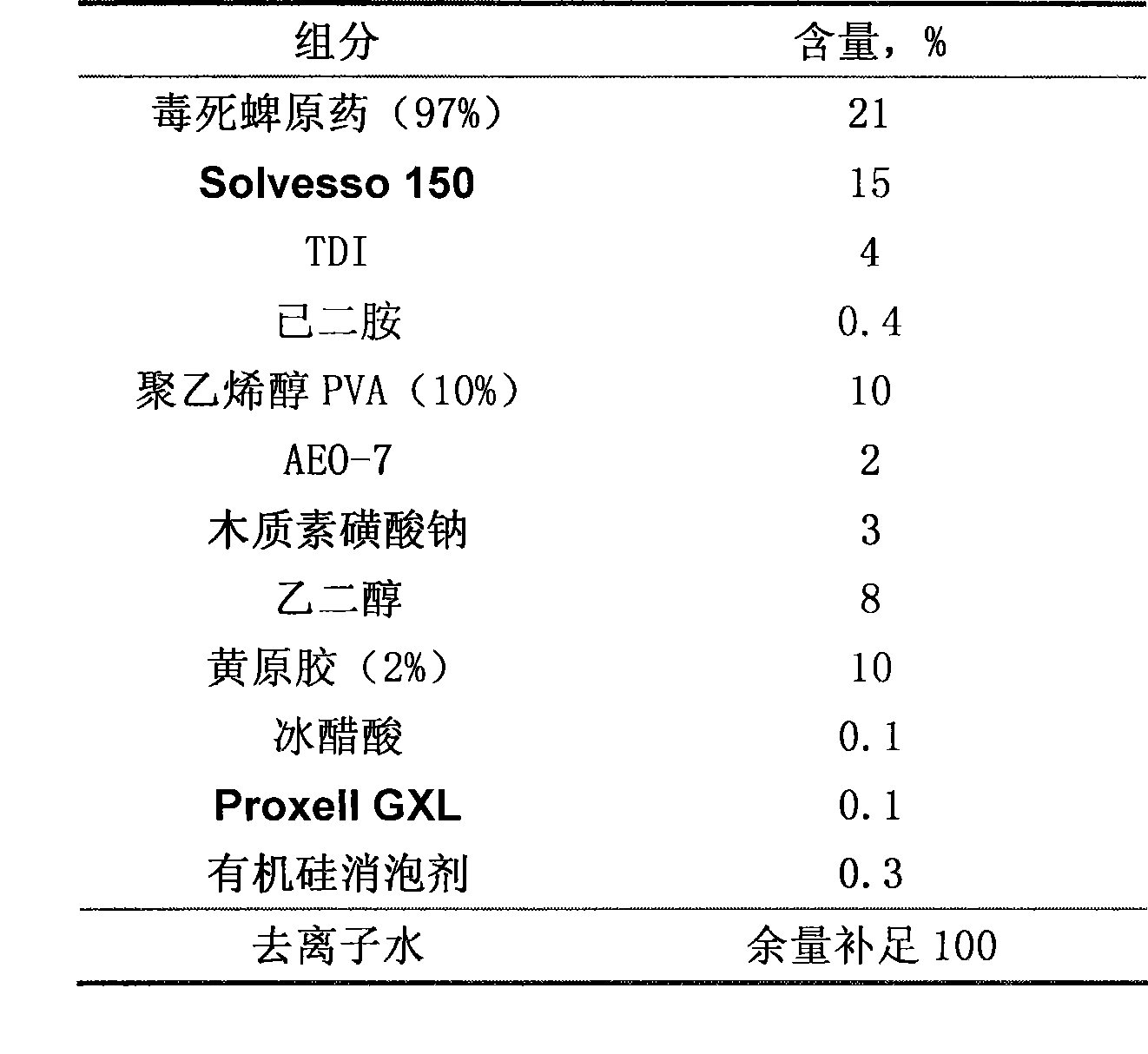

Embodiment 1

[0040] The former medicine of chlorpyrifos (97% content) of 20g is dissolved in the Solvesso 150 aromatic hydrocarbon solvent naphtha (U.S. Exxon Mobil company product) of 15g, then add the toluene diisocyanate TDI (Cangzhou Dahua TDI limited liability company) of 4g and stir evenly ( Oil phase); 2.0g of emulsifier AEO-7 (Nanjing Taihua Chemical Co., Ltd.), 10g of 10% PVA (polyvinyl alcohol) aqueous solution was added to deionized water and stirred (water phase); the configured oil phase Enter the water phase and start high-speed homogenization to form a stable O / W emulsion; start stirring (maintain 600 rpm), then heat the homogenized emulsion to 40°C, and slowly add 0.4g of hexamethylenediamine to maintain Stable capsule wall material curing temperature 8 hours, add dispersant sodium lignosulfonate 3.0g, 8.0g ethylene glycol, 10g xanthan gum (wherein xanthan gum content is 2%) aqueous solution, 0.1g ice Acetic acid was used to adjust the pH value to about 7, 0.1 g of isothiaz...

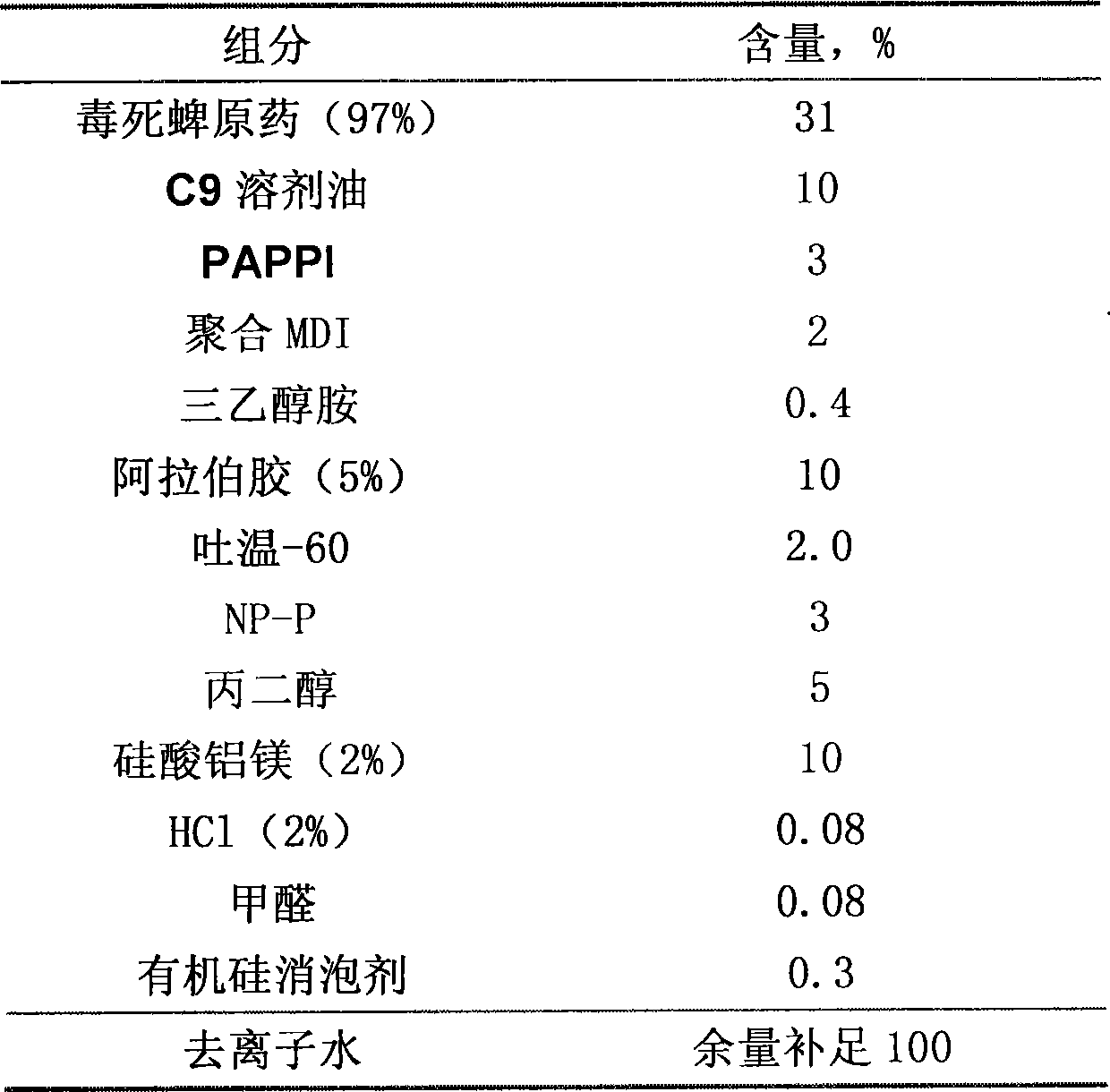

Embodiment 2

[0044] The chlorpyrifos former medicine (97%) of 31g is dissolved in the C9 aromatic hydrocarbon solvent naphtha (Jinling Petrochemical Co., Ltd.) of 10g, then adds the polyphenyl polymethylene polyisocyanate PAPI (Germany Bayer company) of 3g and 2.0g Diphenylmethane diisocyanate MDI (Yantai Wanhua Polyurethane Co., Ltd.) is stirred evenly to be an oil phase; 2.0 g of emulsifier Tween-60 (Jiangsu Haian Petrochemical Co., Ltd.), 10 g of gum arabic (wherein the content of gum arabic 5%) aqueous solution into deionized water and stir to form a water phase; put the prepared oil phase into the water phase and turn on high-speed homogenization to form a stable O / W emulsion; turn on stirring (maintain 700 rpm), and then put The homogenized emulsion is warmed up to 70°C, and at the same time, 0.4g of triethanolamine is slowly added to maintain a stable solidification temperature of the capsule wall material for 3 hours, and then 3.0g of phosphate ester dispersant NP-P (Nanjing Taihua ...

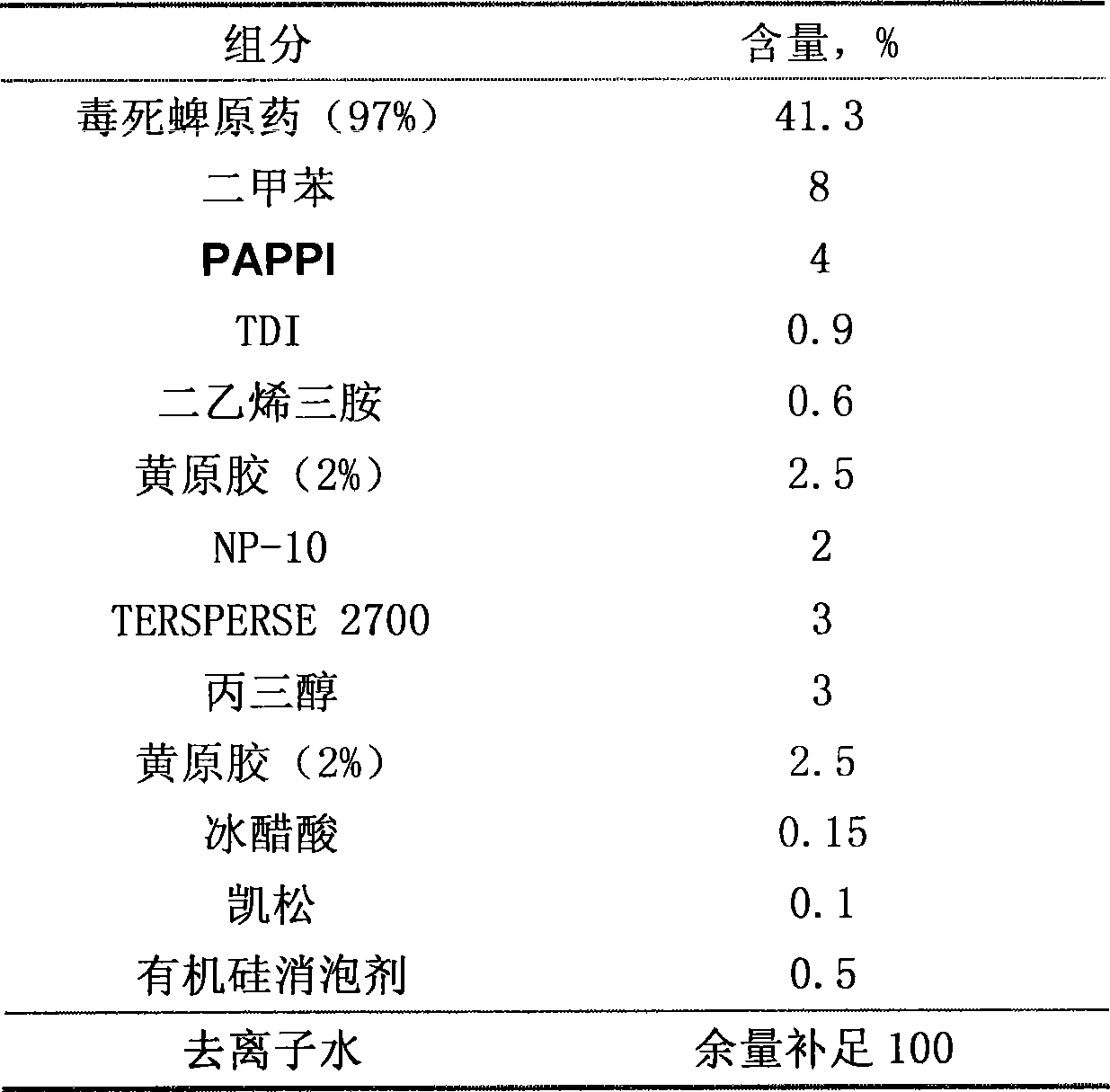

Embodiment 3

[0048]The former medicine (97%) of chlorpyrifos of 41.3g is thermally dissolved in the xylene of 8g, then adds the polyphenyl polymethylene polyisocyanate PAPI (Bayer Company of Germany) of 4g and the toluene diisocyanate TDI (Cangzhou University) of 0.9g (Nanjing Taihua Co., Ltd.) and stir evenly to be an oil phase; add 2.0 g of emulsifier NP-10 (Nanjing Taihua Co., Ltd.), 5 g of xanthan gum (1% content) aqueous solution into deionized water and stir to be a water phase; Put the prepared oil phase into the water phase and turn on the high-speed homogenization to form a stable O / W emulsion; turn on the stirring (maintain 800 rpm), then raise the temperature of the homogenized emulsion to 50°C, and slowly add 0.6g Diethylenetriamine, maintain stable wall material solidification temperature for 7 hours, then add 3.0g carboxylate dispersant TERSPERSE 2700 (Huntsman company), 3.0g glycerol, 2.5g xanthan gum (2 % content) aqueous solution, 0.15g of glacial acetic acid to adjust the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com