Production method of dual-brush type sealing device

A sealing device, double brush technology, applied in the direction of engine sealing, leakage prevention, engine components, etc., can solve the problem of difficulty in ensuring that the brush wire angle meets the requirements, the brush seal sealing effect is not obvious, and the brush wire arrangement is not neat. and other problems, to achieve the effect of easy realization, good sealing effect and neat arrangement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention is further described in conjunction with accompanying drawing:

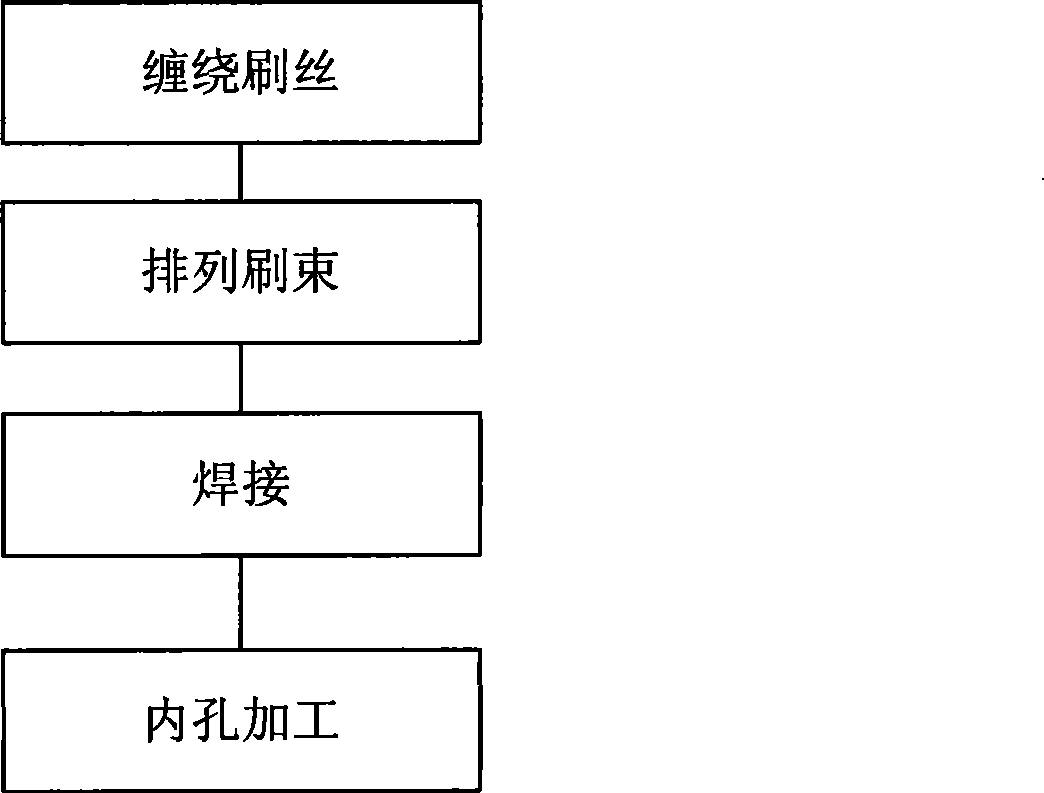

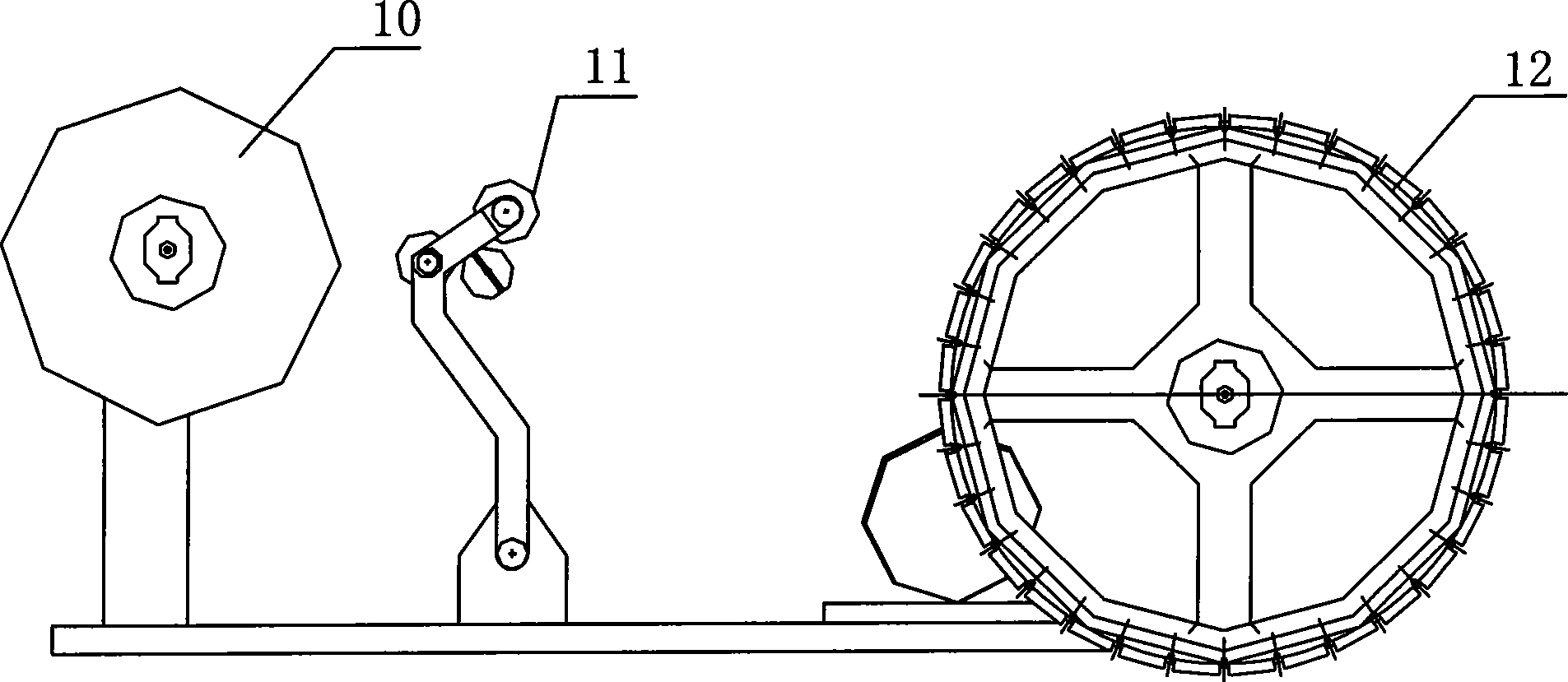

[0026] Such as figure 1 As shown, the program flow chart of the present invention includes the following steps: (1) winding the brush wire, winding the metal wire into a brush bundle, and cutting the brush bundle into small sections of a specified length, with an error of 0.1 to 0.5mm; (2) arranging Brush beams, arrange the brush beams between the upper plate and the lower plate, and the tangent line between the brush beams and the circle between the upper plate and the lower plate is 40°~53°; (3) Welding, welding the arranged brush beams on the upper plate Between the plate and the lower plate; (4) processing the inner hole, cutting off the excess length of the brush bundle. The metal wire adopts SG37A, and the upper and lower plates described above adopt GH626. (5) Weld the two seal assemblies together to form a duplex brush seal.

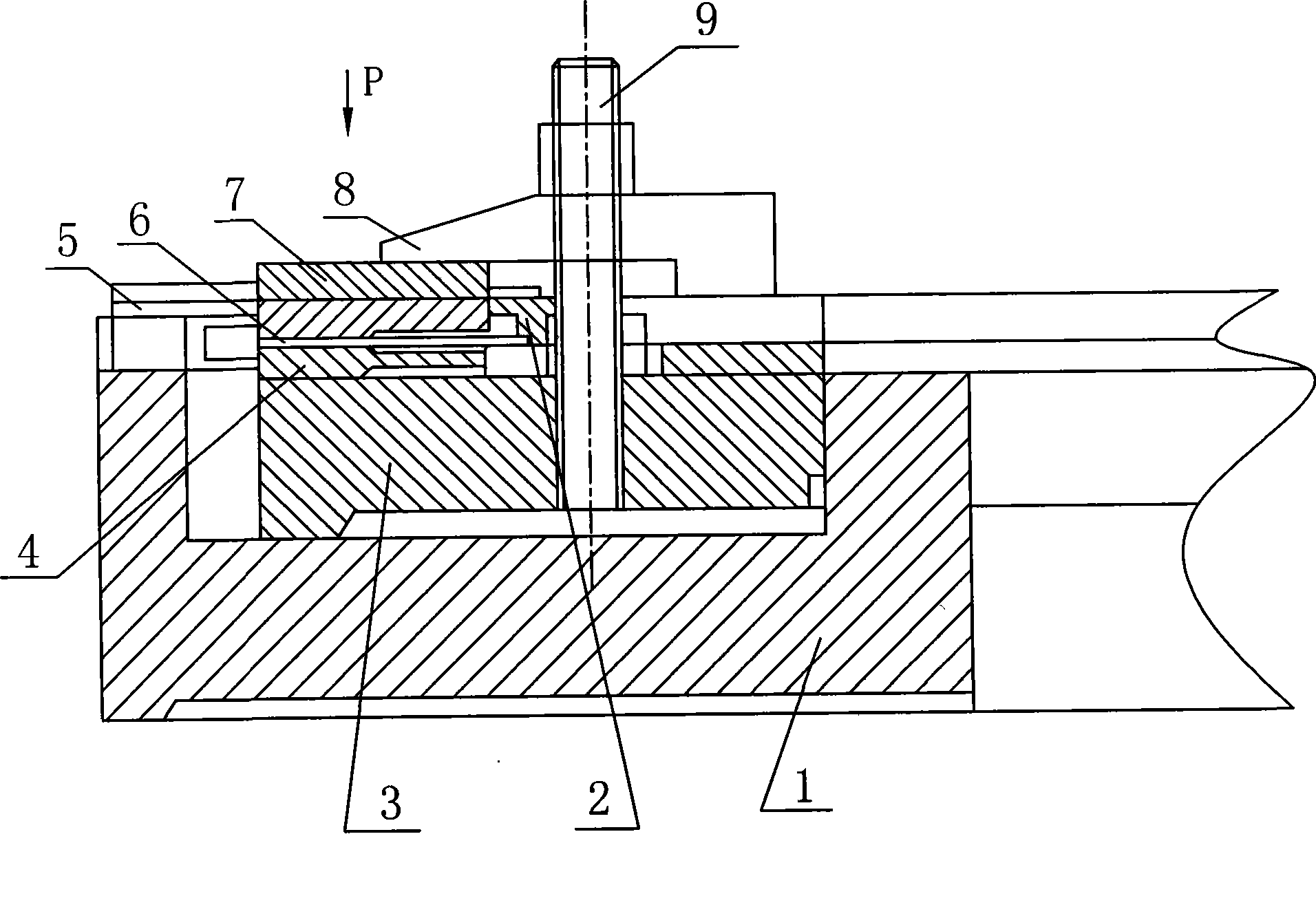

[0027] After the welding in step (3), the weldi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com