Throttling stop valve with throttling and cut-off dual function

A throttling cut-off valve and dual-function technology, which is applied in the field of throttling stop valves, can solve the problems of affecting air-conditioning performance, large vibration and noise of the throttle, and leakage, so as to reduce material consumption, solve high noise and reduce costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

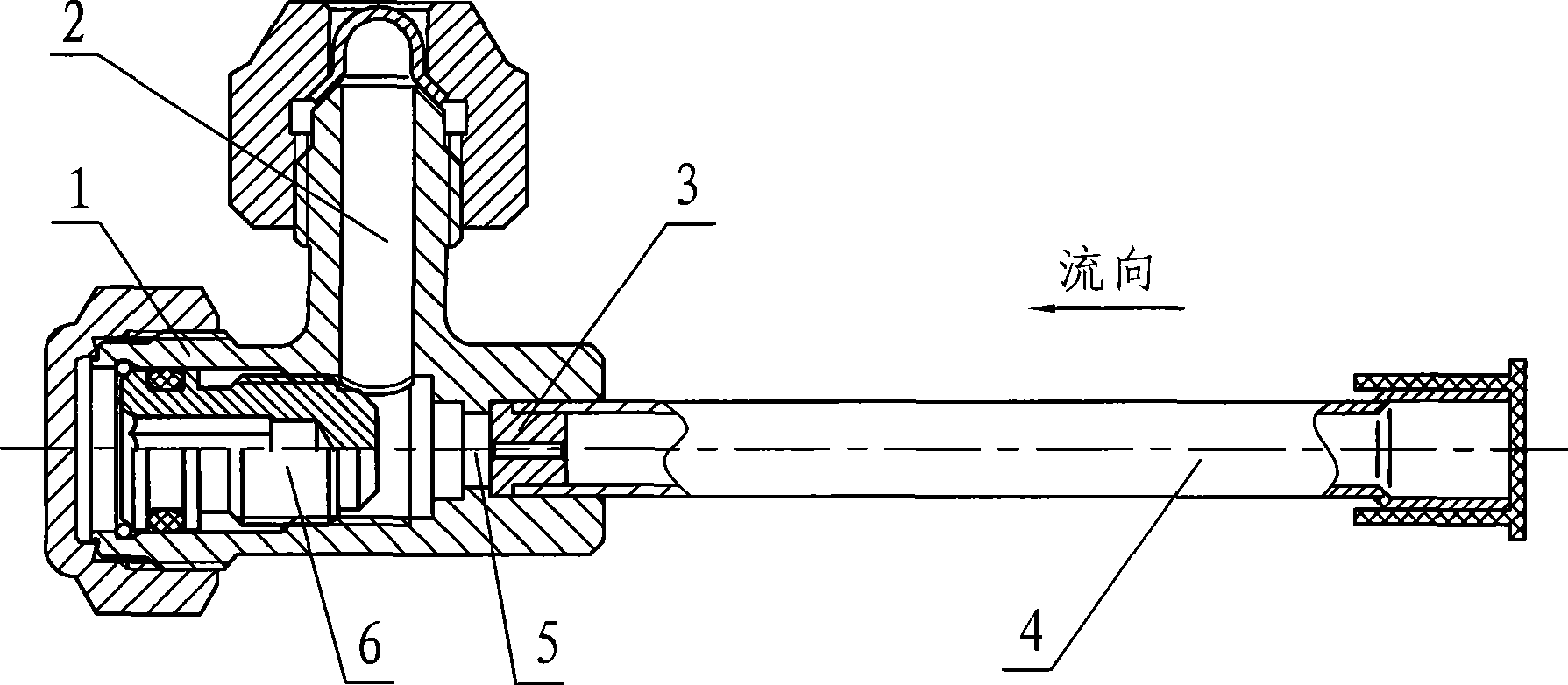

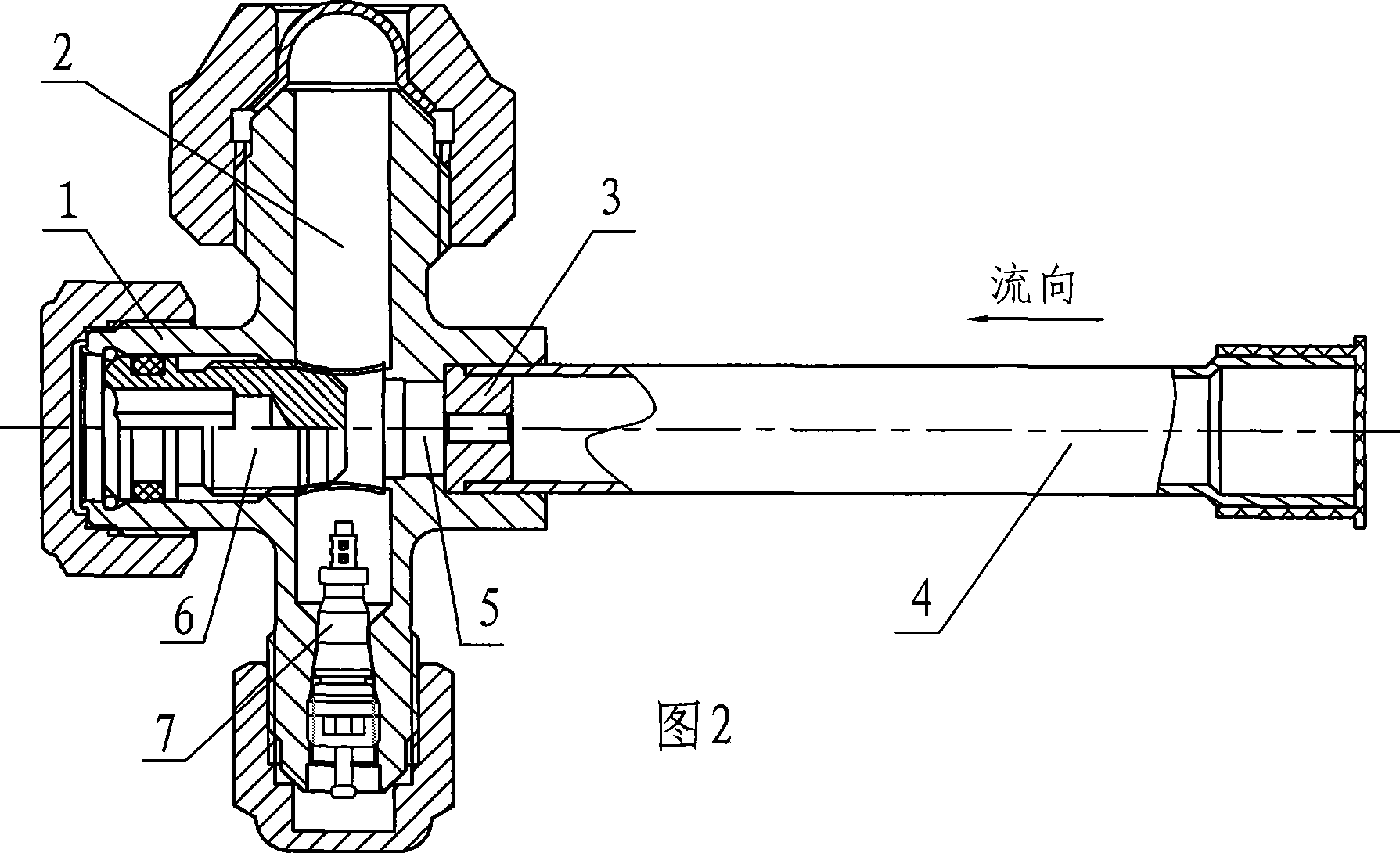

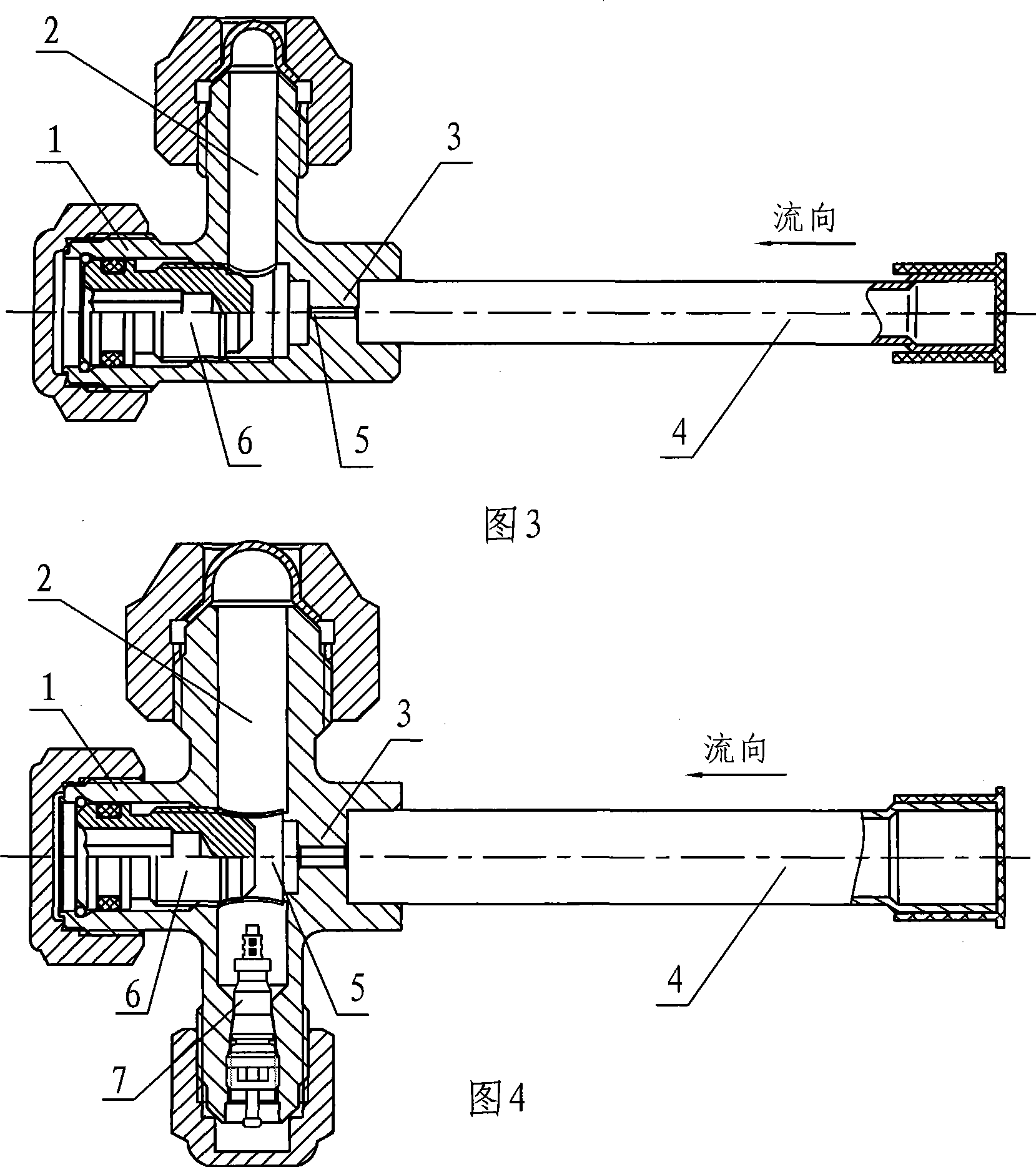

[0019] Such as figure 1 , 2, 3, 4, 5, 6, a throttling shut-off valve with dual functions of throttling and shut-off, including a valve body 1, a connecting pipe 4, a shut-off spool 6, and a throttling spool 3, The throttle spool 3 is arranged on the valve body 1 .

[0020] Such as figure 1 , 2, the throttle spool 3 is embedded, the spool 3 is embedded in one end of the connecting pipe 4, and is installed on the inlet port 5 of the stop valve together with the connecting pipe 4, the throttle spool 3 is a boss type, Closely matched with the connecting pipe 4 and the inlet port 5 of the stop valve, a throttle hole is arranged in the axial direction of the throttle valve core.

[0021] As shown in Figures 3 and 4, the throttle spool 3 is integrated, the spool 3 is integrated with the valve body 1, and is arranged on the inlet port 5 of the flow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com