Hot gas defrosting method for air supply heat pump

A hot gas defrosting and heat pump technology, applied in heat pumps, lighting and heating equipment, compressors with reversible cycles, etc., can solve problems affecting performance, wasting energy, and unable to accurately reflect the frosting of the evaporator, and achieve energy efficiency ratio Optimizing and saving energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Embodiment of heat pump defrosting device:

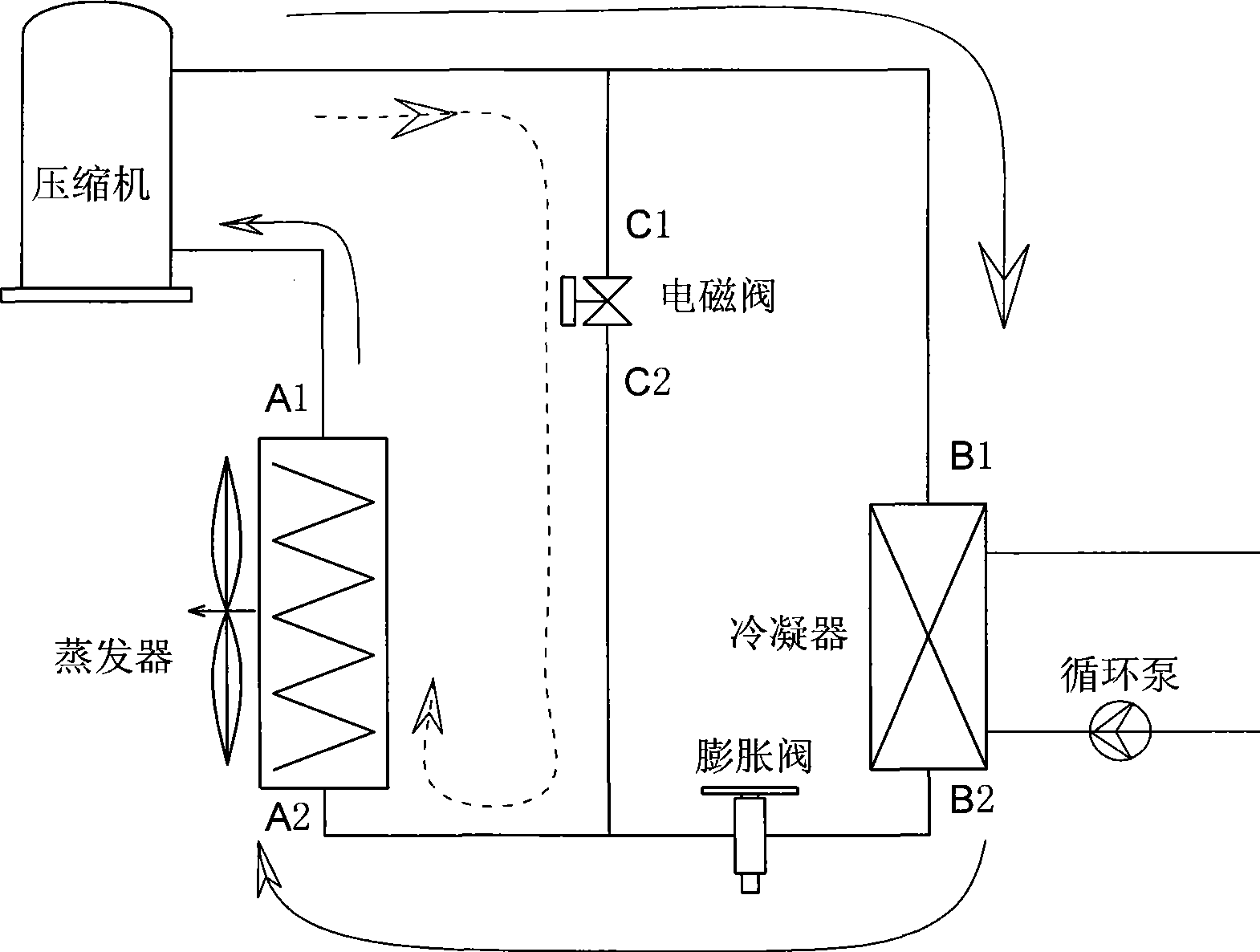

[0025] Such as figure 1 , which is a schematic structural diagram of an embodiment of the heat pump hot gas defrosting device of the present invention. It includes. The air source heat pump includes a controller (not shown), a compressor, an evaporator, an expansion valve, a condenser, a circulating pump, and an electric control valve, the controller includes a single-chip MCU, and the optimal defrosting time b is set Stored in the memory of the single-chip MCU of the controller after being determined.

[0026] The inlet of the compressor is connected to the refrigerant port A1 of the evaporator, and the outlet of the compressor is connected to the port C1 of the electric control valve and the refrigerant port B1 of the condenser, and the other port C2 of the electric control valve is connected to The other refrigerant port A2 of the evaporator, the other refrigerant port B2 of the condenser and the refrigerant port A2 of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com