Method for fast and effectively improving measurement accuracy of 12 elemental composition in stainless steel

A technology of element composition and stainless steel, applied in the direction of thermal excitation analysis, material excitation analysis, etc., to achieve the effect of high measurement precision, high precision, and wide linear range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

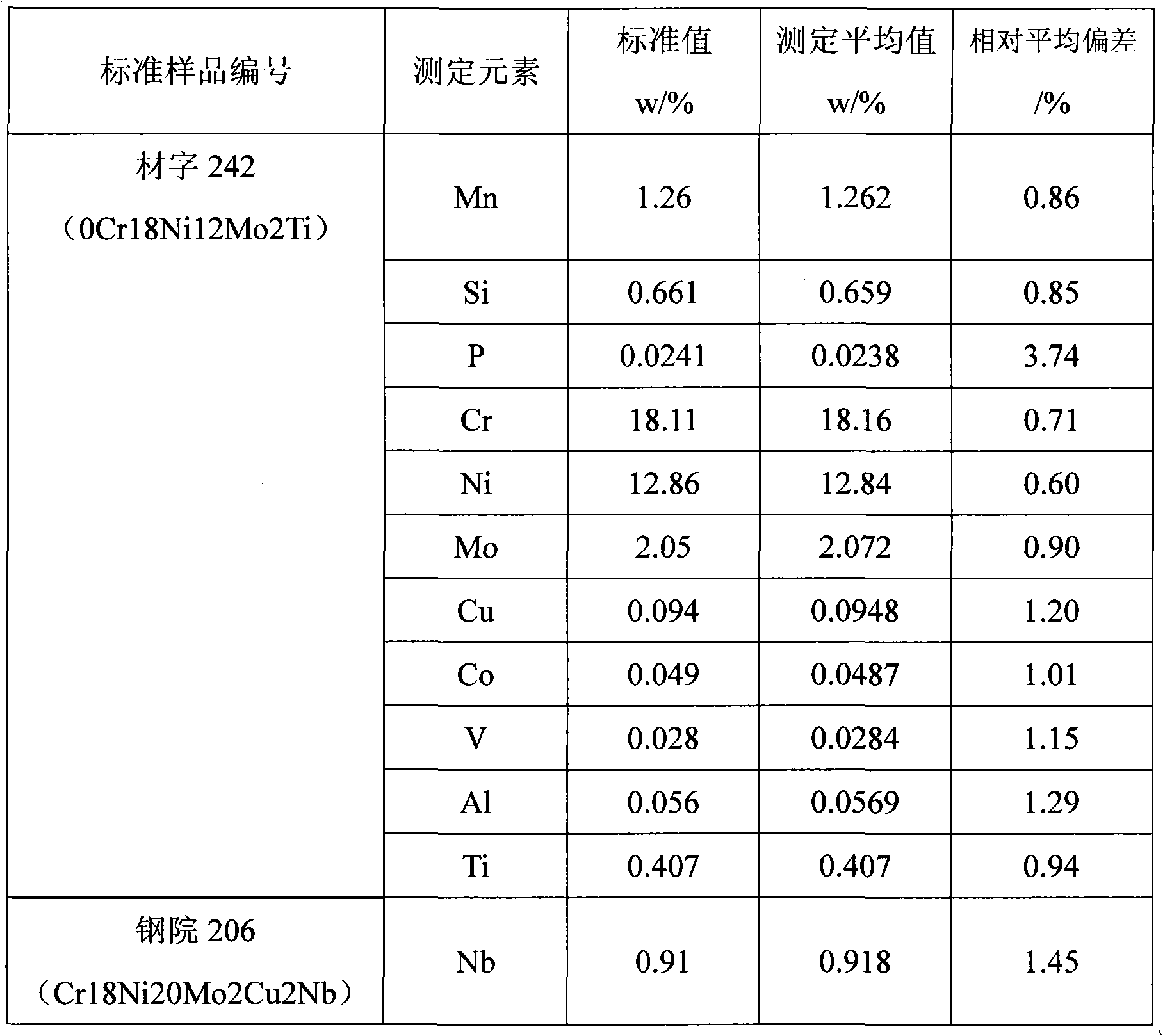

Examples

Embodiment Construction

[0027] Step 1. Prepare instruments and equipment

[0028] 1. Model 1725 inductively coupled full-spectrum direct-reading plasma emission spectrometer (Varian Corporation, USA);

[0029] 1.2EAT-20T analytical experimental ultrapure water device;

[0030] 1.3 Mettler-Toledo Al204 electronic balance;

[0031] 1.4LabTech H150 water circulation cooler;

[0032] 1.5DJW-10KVA automatic AC regulated power supply.

[0033] Connect the plasma gas to the plasma emission spectrometer through the pipeline, access the auxiliary gas through the pipeline in the middle layer of the plasma torch of the plasma emission spectrometer, install the atomizer in the plasma emission spectrometer, and connect the water circulation cooler to the plasma emission spectrometer:

[0034] Step 2. Determine the working parameters of the instrument

[0035] RF generator power: 1.15 kW; plasma gas flow: 15.0 liters / min; auxiliary gas flow: 1.50 liters / min; atomizing gas pressure: 200 kPa; one reading time: 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com