Patents

Literature

30results about How to "High measurement precision" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

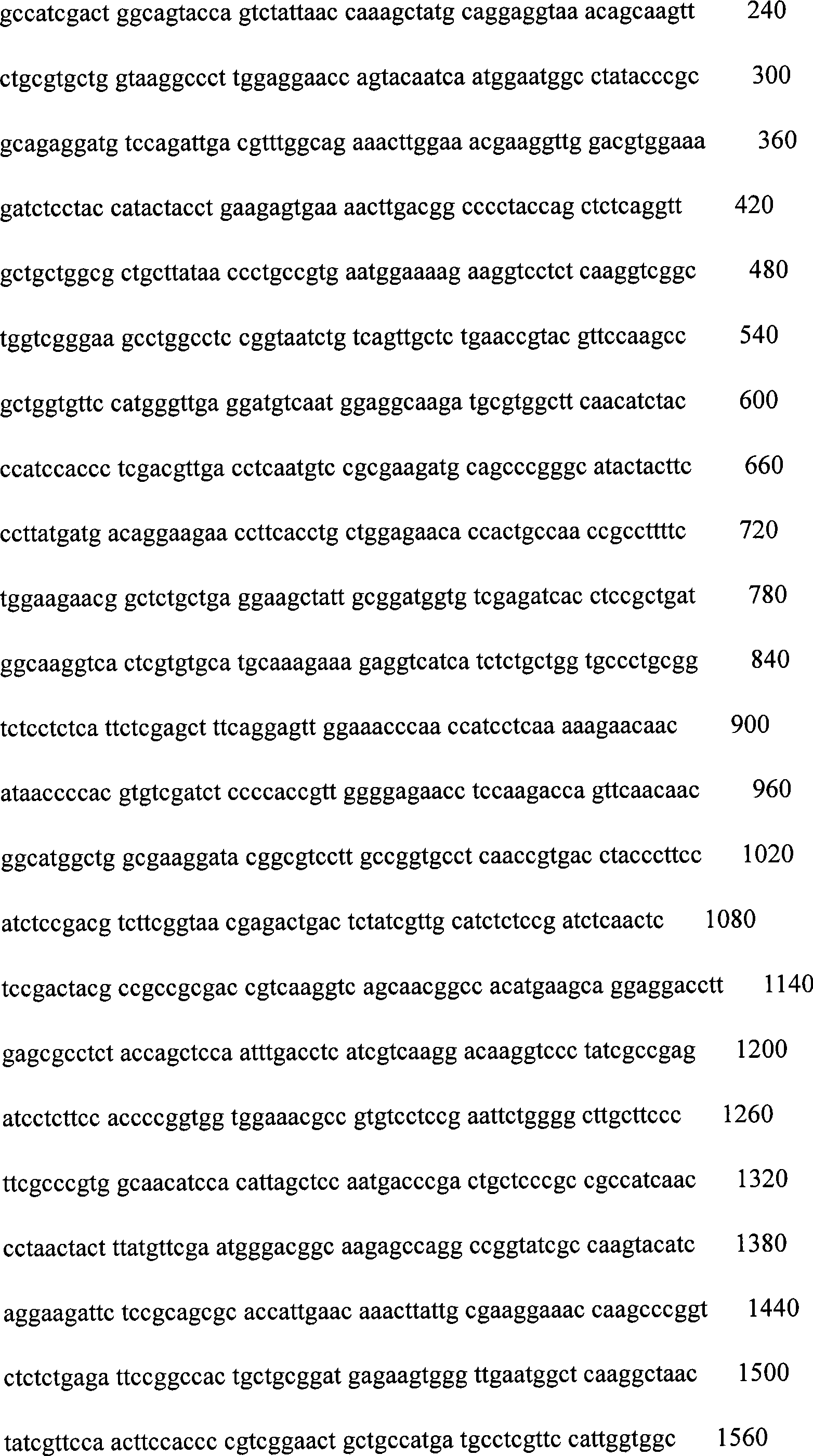

Strain in use sensor of measuring oxygen quantity needed by industrial wastewater or seawater biochemistry-method for cultivating bacillus licheniformis

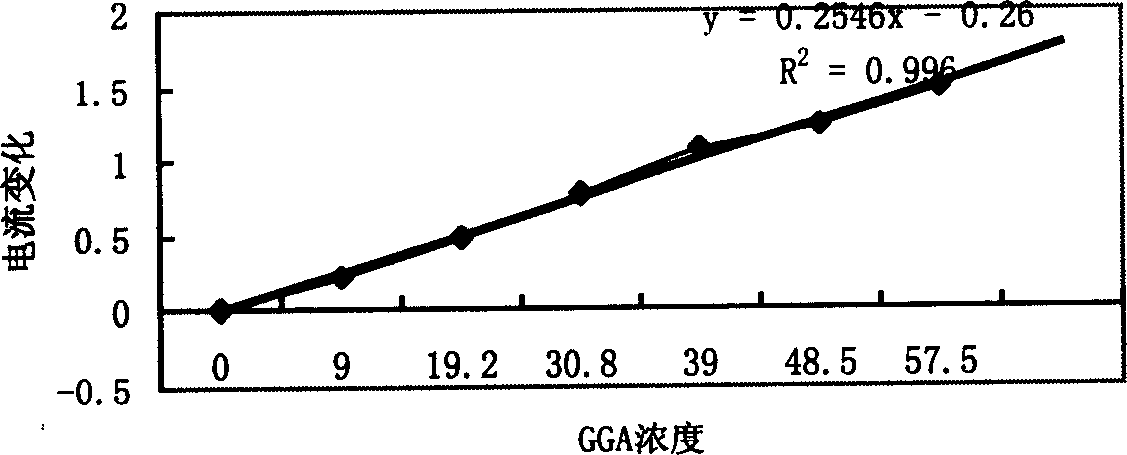

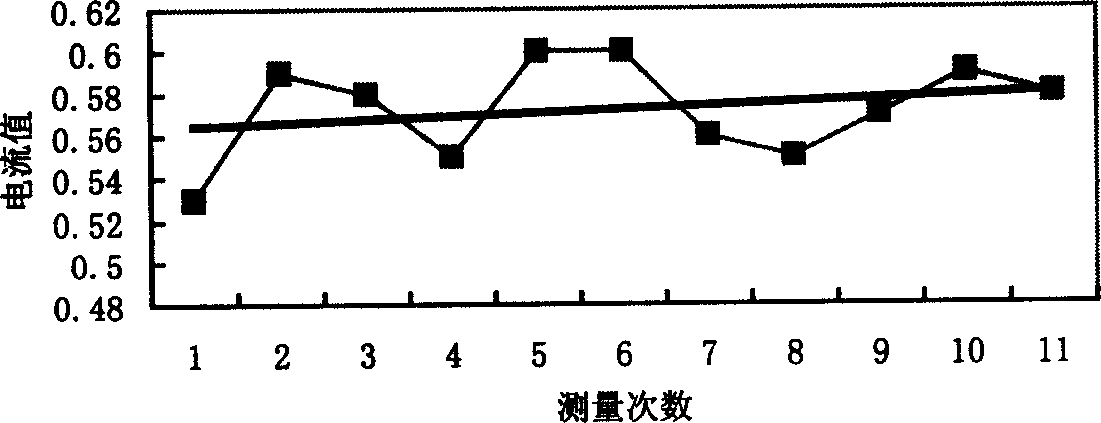

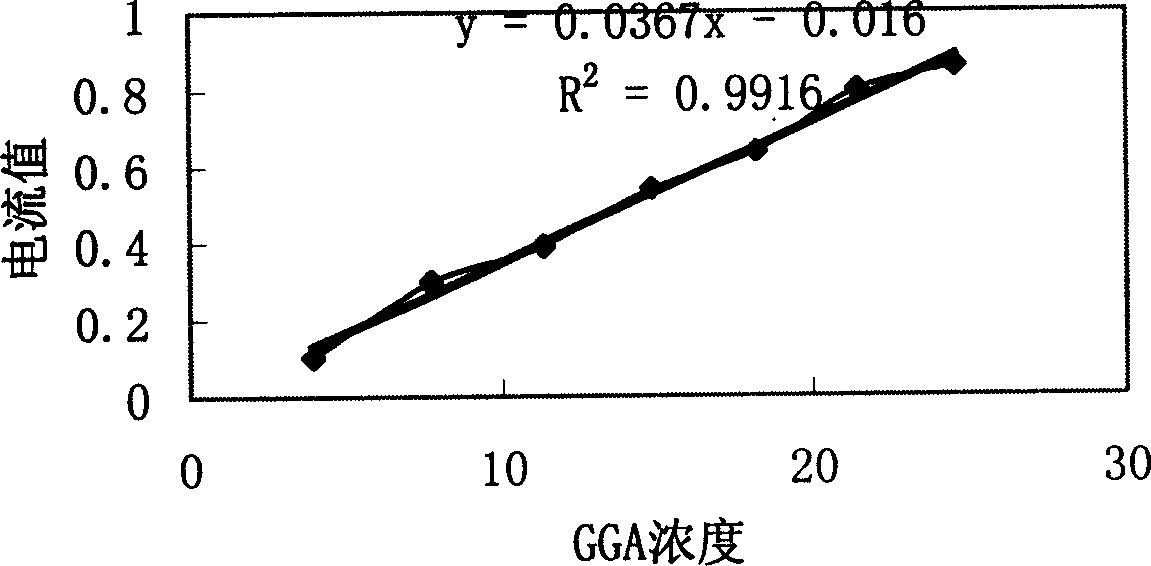

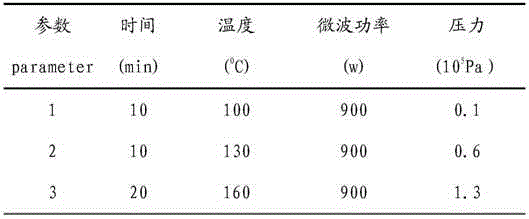

InactiveCN1563354AHigh measurement precisionGood correlationBacteriaBiological water/sewage treatmentBacillus licheniformisTransducer

A method for cultivating Bacillus licheniformis being applied in BOD biological transducer includes separating and screening waste water from starch plant for obtaining a high breath-strength aerobic bacterial strain, acclimating the bacterial strain to be operational bacterial strain set in BOD biological transducer for in dustrial waste water or seawater.

Owner:HEBEI UNIVERSITY OF SCIENCE AND TECHNOLOGY

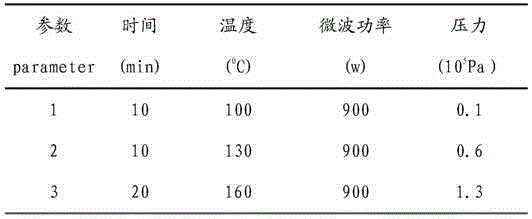

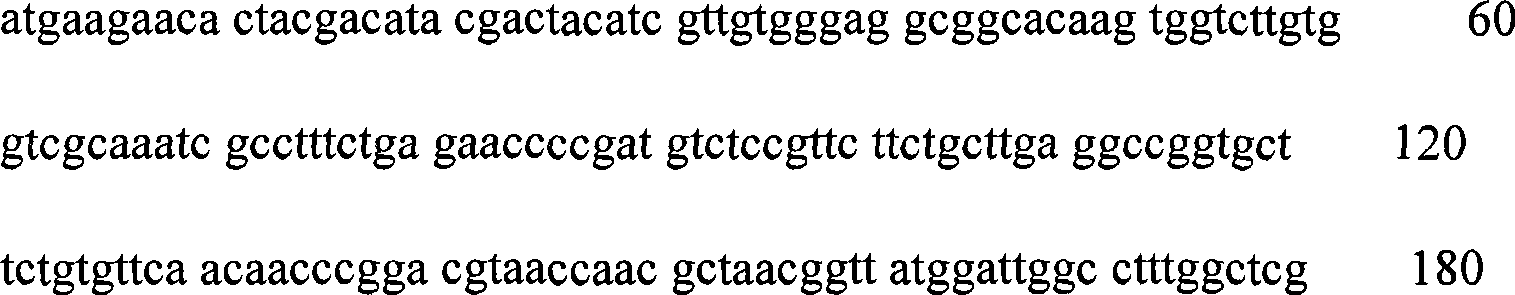

Method for measuring content of heavy metals in edible mushrooms by ICP-AES (inductively coupled plasma-atomic emission spectrometry)

InactiveCN104949960AAvoid enteringMeasurement method scienceAnalysis by thermal excitationPesticide residueEdible mushroom

The invention discloses a method for measuring the content of heavy metals in edible mushrooms by ICP-AES (inductively coupled plasma-atomic emission spectrometry), and mainly solves the technical problems that the specific contents of pesticide residues and overproof heavy metals in the edible mushrooms cannot be measured. The method is implemented by the following steps: 1, preparing an experimental material; and 2, pre-treating a sample, preparing a standard solution, measuring working parameters of an instrument, constructing a standard curve and measuring the sample, wherein under the conditions, by adoption of the ICP-AES method, the content of the heavy metals in a mushroom solution is measured; each sample is measured for three times in parallel, and then an average value is calculated; and the contents of all elements in the edible mushrooms can be obtained by carrying out unit conversion on measured data. The measurement method is scientific, accurate, high in measurement precision, quick in measurement and wide in linear range and has the advantages of measuring various elements simultaneously and the like. By the method for measuring harmful substances, poisonous and harmful edible mushrooms can be prevented from entering the market, and the development of an edible mushroom cultivation technology is promoted; and therefore, the method disclosed by the invention has a good popularization prospect.

Owner:SHENYANG NORMAL UNIV

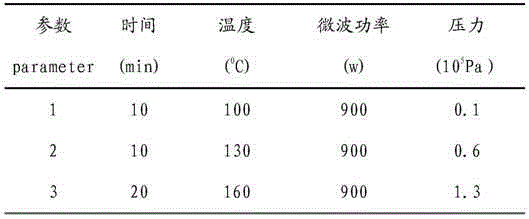

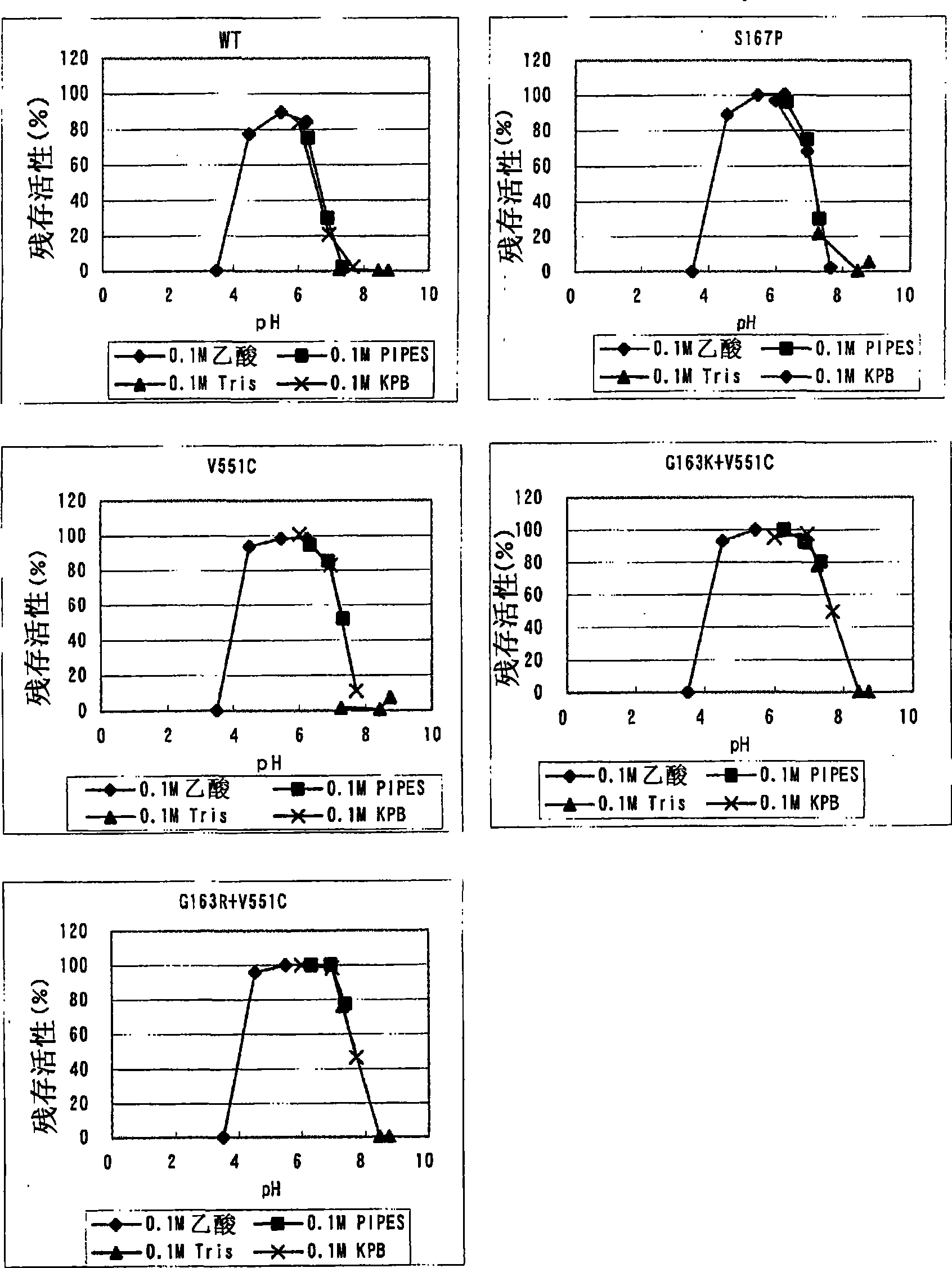

Modified flavine-adenine-dinucleotide-dependent glucose dehydrogenase

ActiveCN101535476AEasy to useReduce heat inactivationFungiBacteriaFlavine adenine dinucleotideWild type

Disclosed is a modified flavine-adenine-dinucleotide-dependent glucose dehydrogenase (FADGDH) having an improved thermal stability compared to a wild-type FADGDH, which is preferably derived from a eukaryote, more preferably derived from a filamentous fungus, still more preferably derived from a bacterium belonging to the genus Aspergillus. For example, the modified FADGDH has a primary structure having the substitution, deletion, insertion or addition of at least one amino acid residue in the amino acid sequence for FADGDH depicted in SEQ ID NO:2 or 46 in the Sequence Listing.

Owner:TOYO TOYOBO CO LTD

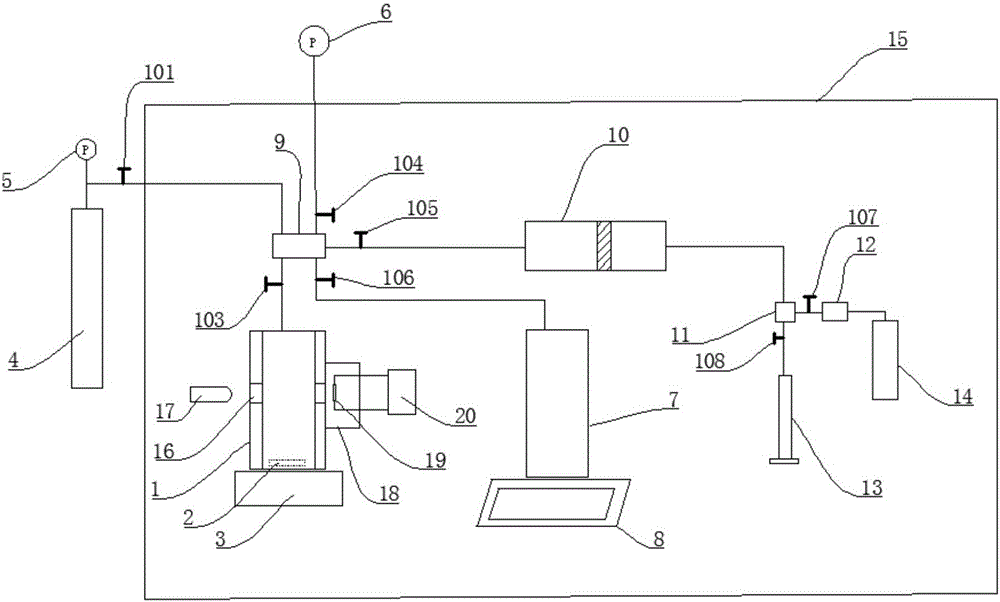

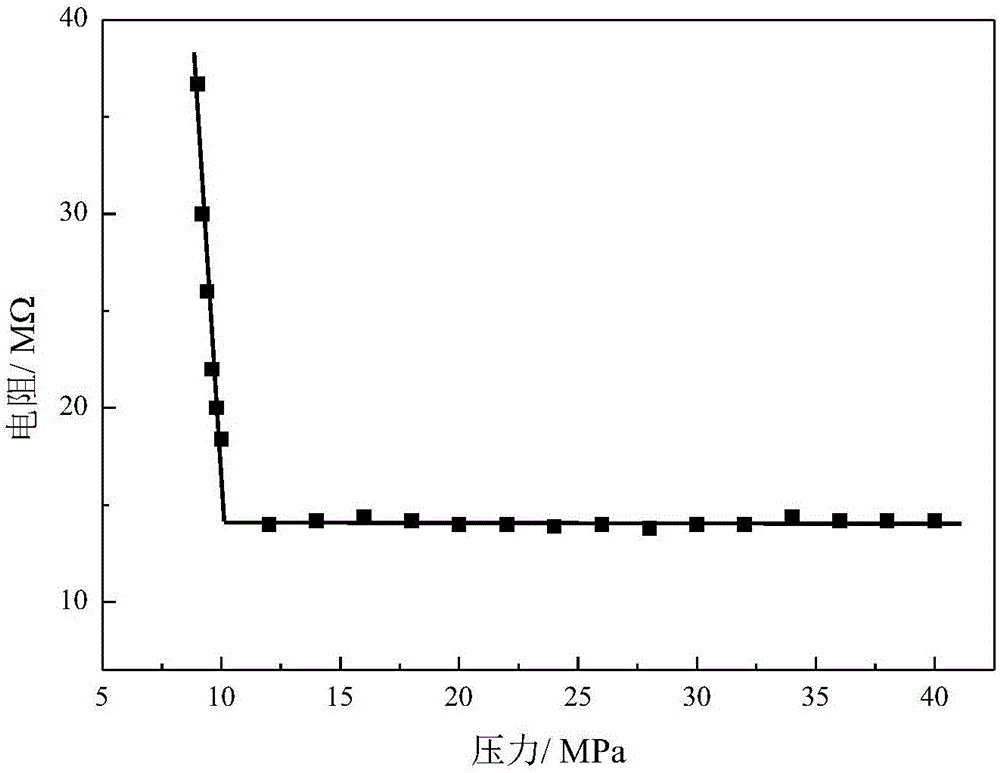

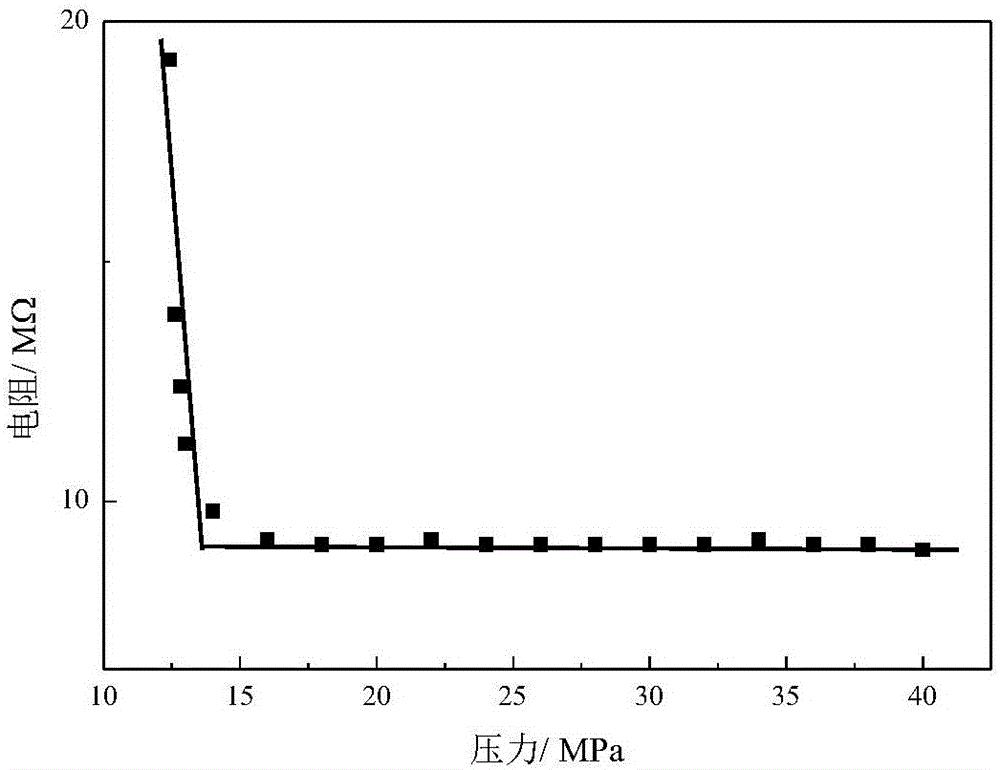

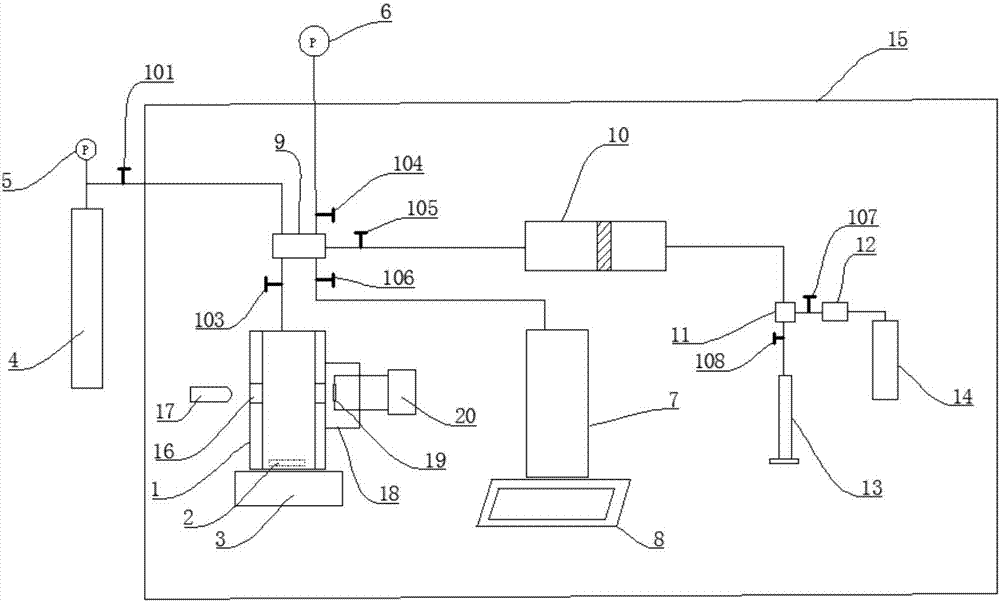

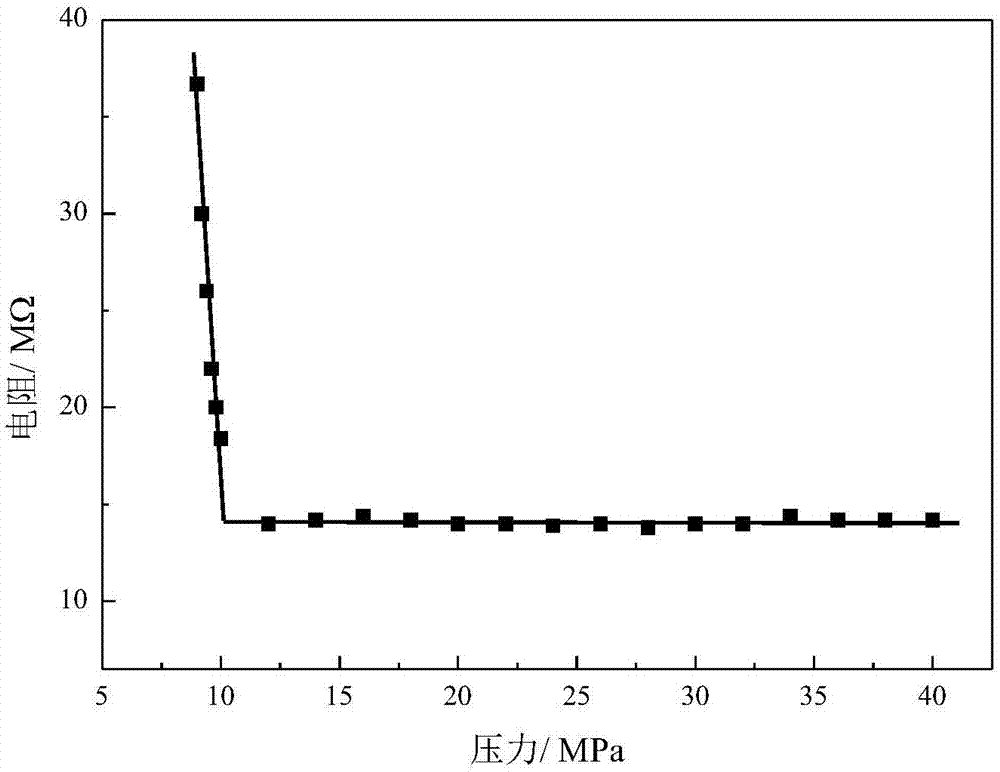

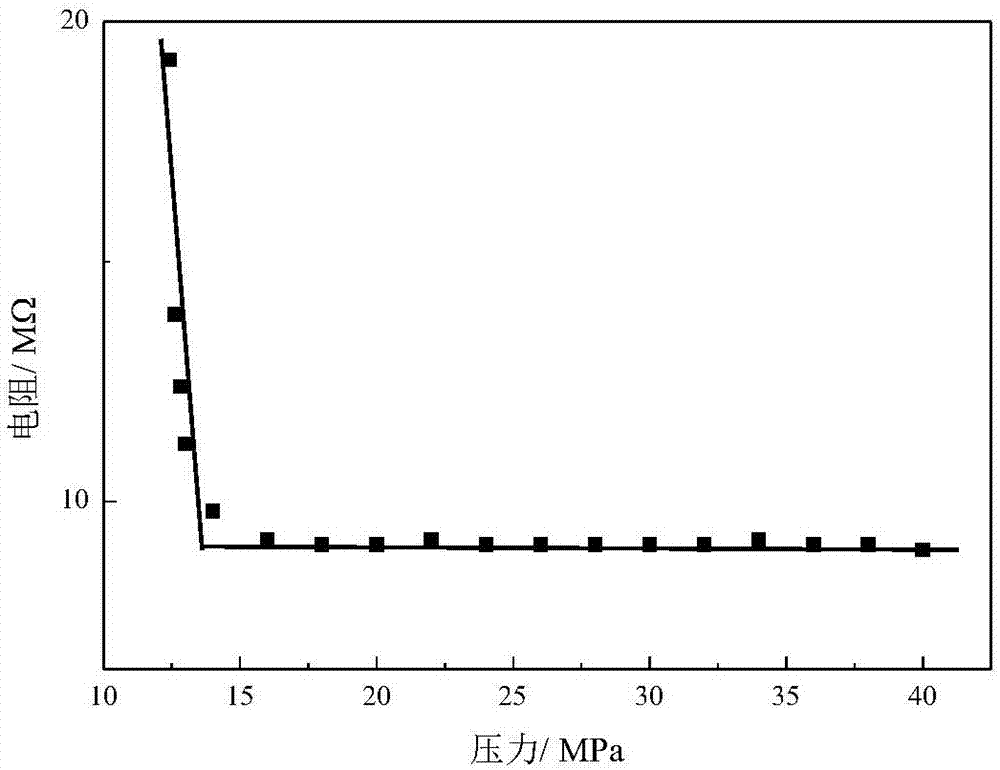

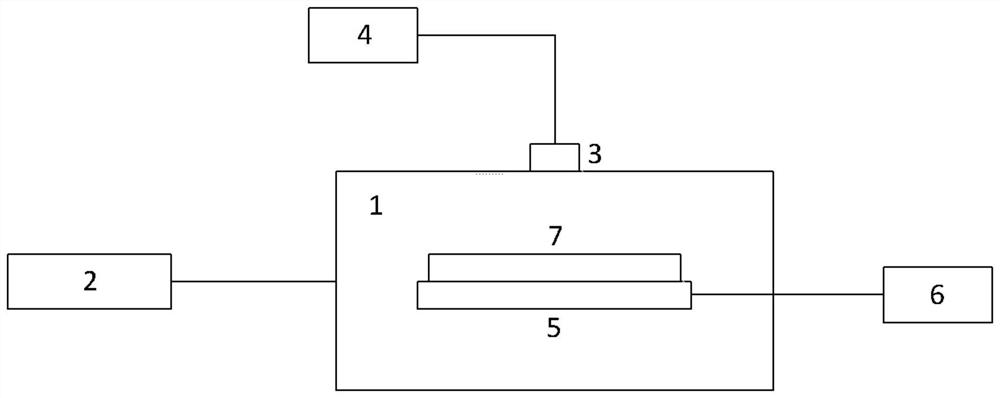

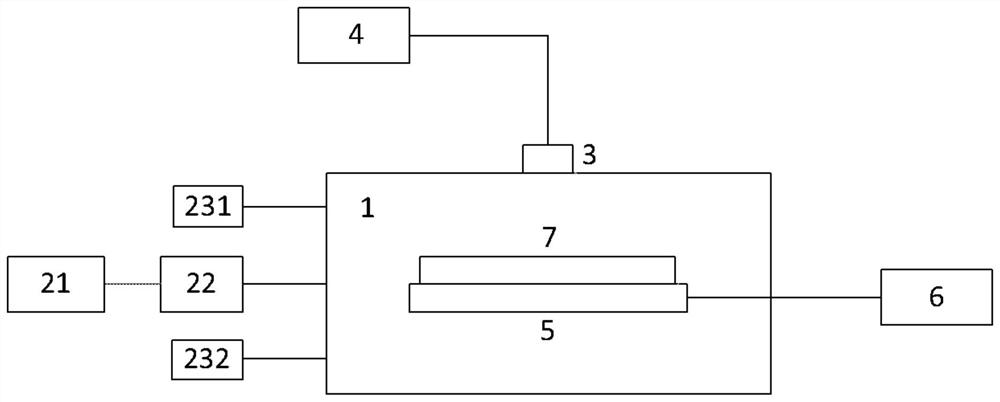

Apparatus and method for measuring cloud point pressure and density of supercritical CO2 microemulsion system

InactiveCN105890839ASimple structureImprove sealingFluid pressure measurementMaterial resistanceGas cylinderWater storage tank

The invention discloses an apparatus and method for measuring the cloud point pressure and density of a supercritical CO2 microemulsion system. A magneton is arranged in a visual container, an electronic stirrer is arranged under the visual container, and the upper portion of the visual container is connected with a five-way valve. A quartz window is arranged on each of two parallel sides on the lower portion of the visual container, a light source is arranged on the outer side of one quartz window, and an opaque chamber is arranged on the outer side of the other quartz window. A photoresistor connected with a universal meter is arranged in the opaque chamber, and a CO2 gas cylinder is connected with the five-way valve. A second pressure transducer is connected to the five-way valve, one end of an intermediate container is connected to the five-way valve, and the other end of the intermediate container is connected with a three-way valve. A gas tank is connected with the five-way valve, one end of a high-pressure plunger pump is connected to the three-way valve, and the other end of the high-pressure plunger pump is connected with a water storage tank. A liquid volume metering device is connected with the three-way valve. The cloud point pressure of a supercritical CO2 microemulsion system and the density of the supercritical CO2 microemulsion system under the cloud point pressure can be obtained under same condition, the influence of minimal difference in parallel experiment processes can be minimized, and important basic data for designing construction scheme of an oil field can be provided.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Method of utilizing ICP-AES to measure content of tungsten in ferromolybdenum

InactiveCN106770199AQuick checkQuick monitoringAnalysis by thermal excitationSpectrographUltimate tensile strength

The invention discloses a method of utilizing ICP-AES to measure the content of tungsten in ferromolybdenum. The method comprises the following steps: step one, weighing a ferromolybdenum sample; step two, preparing a ferromolybdenum sample solution and a ferromolybdenum sample blank solution; step three, preparing work curve solutions; step four, adopting inductive coupling plasma emission spectrograph (ICP-AES) to measure the intensities of the work curve solutions, and drawing a work curve by taking the concentrations of the work curve solutions as the horizontal coordinate and the intensities of the work curve solutions as the vertical coordinate; step five, drawing a work curve; step six, measuring the content of tungsten in the ferromolybdenum sample solution; and step seven, calculating the content of tungsten in the ferromolybdenum sample. The provided measurement method has the advantages of little using amount of ferromolybdenum sample, high reliability and precision, quick measuring speed, simpleness, accuracy, high sensitivity, and good stability.

Owner:JINDUICHENG MOLYBDENUM CO LTD

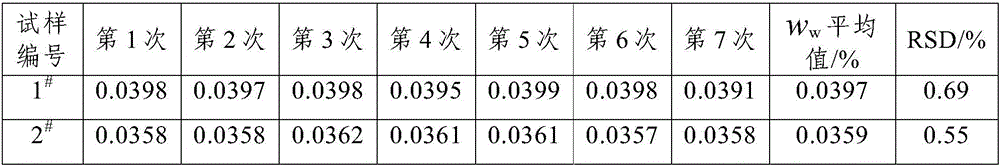

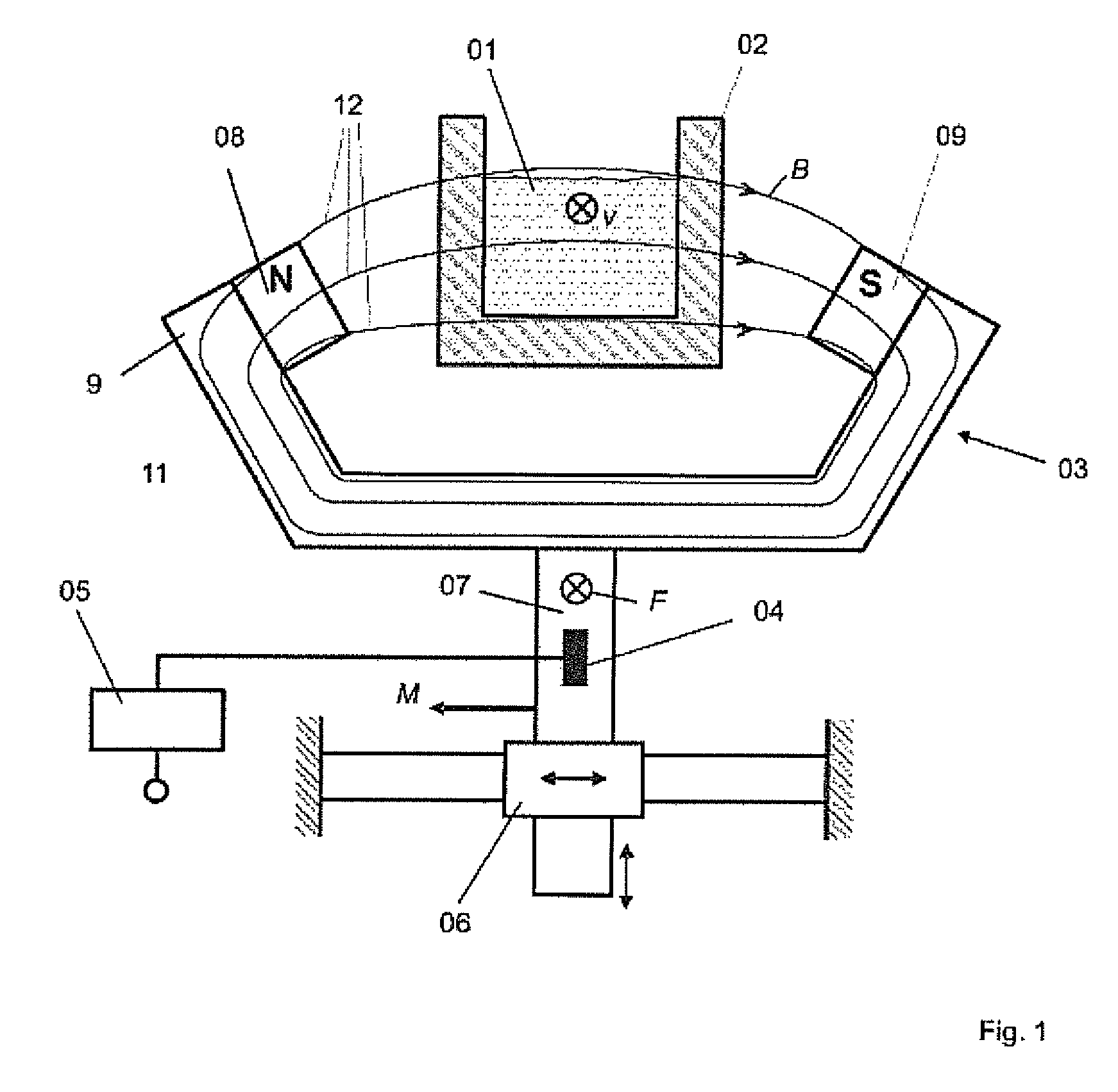

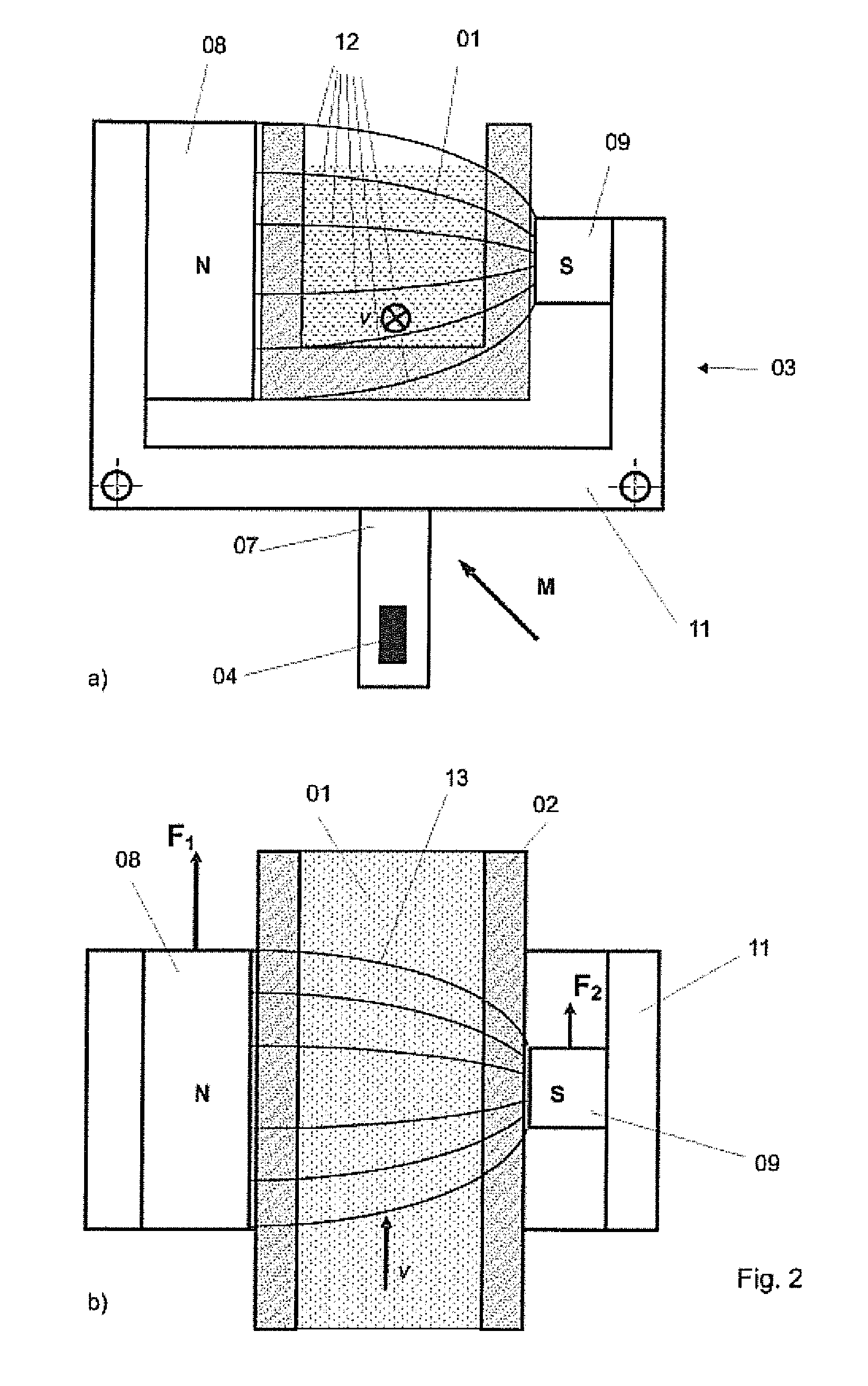

Method and arrangement for the contactless inspection of moving electrically conductive substances

InactiveUS8148976B2High measurement precisionHigh sensitivityVolume/mass flow by electric/magnetic effectsMagnetic property measurementsState parameterEddy current

The invention relates to a method and arrangement for the contactless determination of conductivity-influencing properties and their spatial distribution over the entire cross section of an electrically conductive substance moving in a primary magnetic field (B). The substance may be a liquid or a solid. A simultaneous measurement of a number of mechanical state parameters of the magnetic system is performed (three-dimensional components of the force and the torque), said parameters being variable by the effect of a secondary field on the magnetic system, the secondary field being produced on the basis of eddy currents induced in the substance by the primary field (B). To determine the spatial distribution of the property that is sought, the primary field is changed in intensity or form a number of times and a measurement of the state parameters is carried out for each change. The determination of the properties sought or their distribution takes place by solving an inverse problem using the method of least squares.

Owner:TECH UNIV ILMENAU

Adenosine deaminase detection kit

InactiveCN105586387AGood colorRapid responseMicrobiological testing/measurementBiological material analysisPeroxidaseBovine serum albumin

The invention relates to an adenosine deaminase detection kit. A vessel is contained in the detection kit and filled with liquid for detection, the liquid for detection is prepared from 50-100 mmol / L of glycine buffer solution, 50-80 mmol / L of sodium benzoate, 12 / 18 u / L of purine nucleoside phosphorylase, 30-40 u / L of xanthine oxidase, 200-300 u / L of peroxidase, 30-100 g / L of glyceraldehyde, 0.5 g / L of sodium azide, 10-200 mmol / L of disodium hydrogen phosphate, 100-300 mmol / L of KCl, 40-100 mmol / L of mannitol, 0.1-0.3 ml / L of preservative, 100-150 mmol / L of adenosine, 2-4 mmol / L of 4-aminoantipyrine, 10-15 mmol / L of color developing agent, 20-40 mmol / L of adenine nucleoside and 3-5 g / L of bovine serum albumin. The detection kit has the advantages of being high in determination precision, high in antijamming capacity, suitable for automated rapid determination and capable of creating favorable conditions for routine development of ADA detection application in clinic.

Owner:VISION BIOLOGICAL TECH HEFEI CO LTD

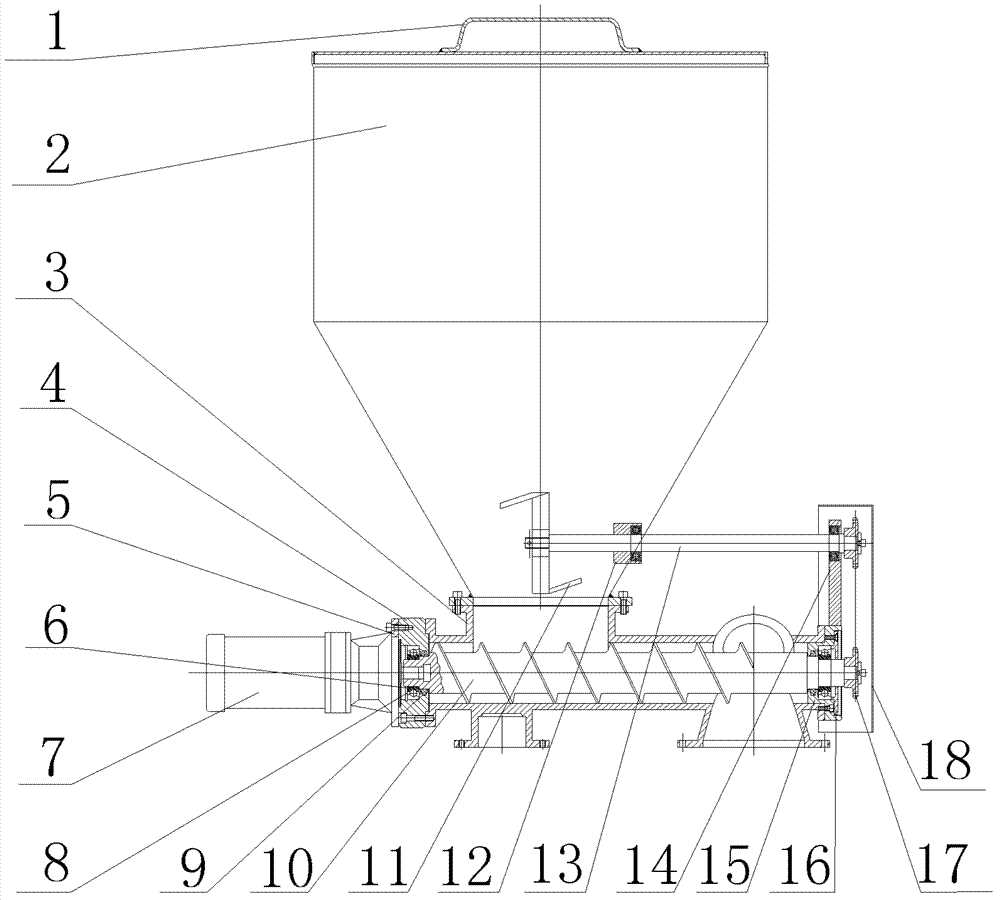

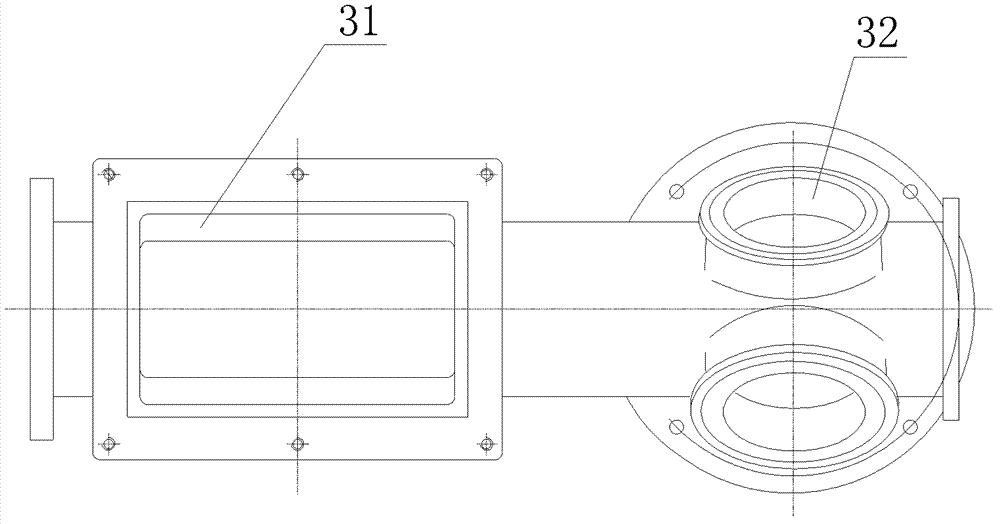

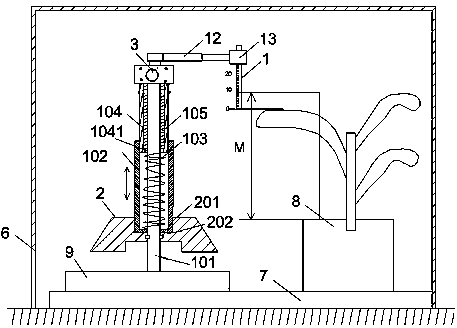

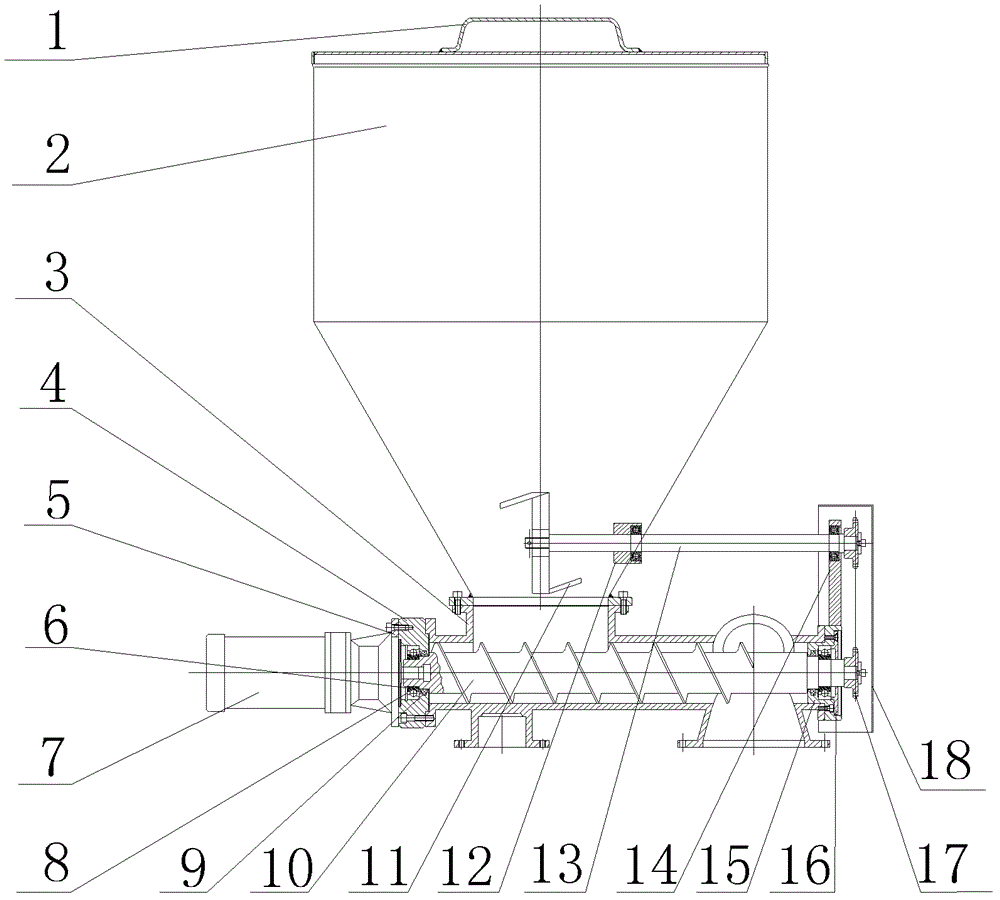

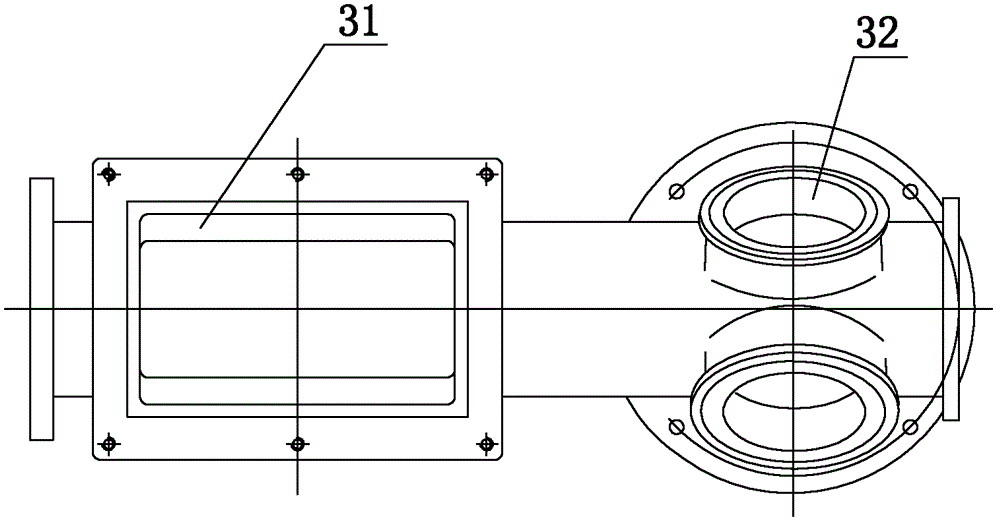

Precise polyvinyl chloride (PVC) high-calcium fill metering and feeding device of conical twin-screw extruder

The invention relates to a precise polyvinyl chloride (PVC) high-calcium fill metering and feeding device of a conical twin-screw extruder. The device comprises a storage device, a feeding device and a stirring device, wherein the storage device consists of a feeding hopper and a hopper cover arranged at the upper part of the feeding hopper; the feeding device comprises a feeding barrel, a driving motor, a motor connecting plate, a motor connecting body, a feeding screw rod, a first bearing seat, a deep groove ball bearing, a bearing check ring, a felt ring and a bearing cover; the stirring device comprises a stirring body, a stirring shaft, a second bearing seat, a shaft sleeve, a sprocket chain and a sprocket cover. Compared with the prior art, the precise PVC high-calcium fill metering and feeding device has the advantages of easiness in blanking, accuracy in feeding, simple and attractive structure, high conveying capacity, no fluctuation, good self-cleaning performance, high metering precision, wide application scope, etc.

Owner:SHANGHAI JINHU EXTRUSION EQUIP

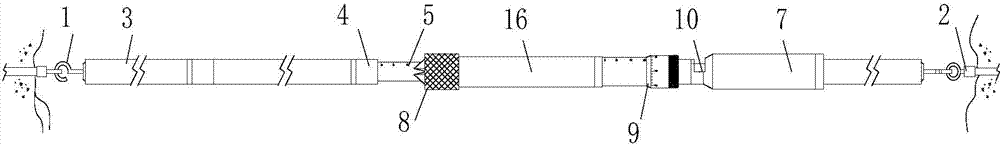

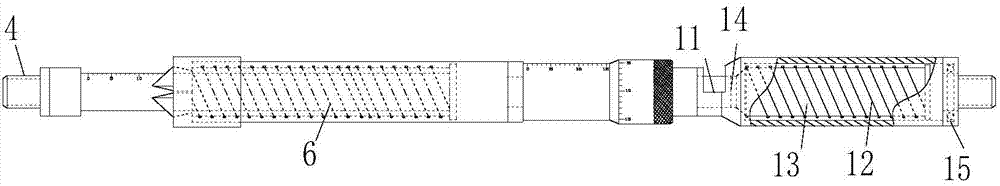

Rod type convergence gauge and using method thereof

InactiveCN103884263ASolve the high point of the measurement sectionResolve connectivityMechanical solid deformation measurementsMicrometerReference window

The invention discloses a rod type convergence gauge and a using method of the rod type convergence gauge. The rod type convergence gauge is mainly formed by connecting a light metal measuring rod, a main measuring and reading rod, a fixing anchor head, a measuring point fixing anchor head and the like. The light metal measuring rod and the main measuring and reading rod are seamlessly connected in a butted mode through a connecting bolt and a connecting nut, and the main measuring and reading rod is mainly composed of a hollow rod body, an internal hidden steel measuring tape, a spring, a metal pressing rod, a locking device, a micrometer caliper, a force measuring spring and a reference window. After the components of the convergence gauge are connected, the measuring tape hidden in the main measuring and reading rod is drawn out, the internal hidden spring is pressed in the process of drawing out the measuring tape, the convergence gauge is tensioned at the same time, then, a measuring tape locking ring is screwed down, and a rough read number is recorded; next, the micrometer caliper connected to one end of the main measuring and reading rod is rotated and meanwhile the force measuring spring is pressed, when the scale mark on a guide rod of the force measuring spring coincides with the scale mark on the reference window arranged on the measuring rod, it is shown that the tensile force is regulated to be accurate, the mantissa is accurately measured and read, and the measuring value can be obtained by adding the mantissa to the rough read number. The rod type convergence gauge has the advantages of being simple in structure, convenient to operate, high and stable in measuring accuracy and high in applicability.

Owner:CHINA UNIV OF MINING & TECH

Total bilirubin detection reagent

InactiveCN106896102AGood colorRapid responseMaterial analysis by observing effect on chemical indicatorVitamin CFreeze-drying

The invention relates to a total bilirubin detection reagent. The detection reagent is composed of the following components: 6-8wt% of a preservative, 160-180mmol / L of Tris-HCl buffer solution, 6-9g / L of sodium dodecyl sulfate, 1-2mmol / L of a surfactant, 3-4mmol / L of sodium metavanadate, 70-90KU / L of ascorbic acid oxidase, 6-8wt% of Triton x-100, 30-40mmol / L of phosphatic buffer solution, 1-2wt% of a preservative, 3mmol / L of a chemical oxidant, 2-3wt% of a freeze-drying protective agent, 50-60mmol / L of NaCl, 1-2g / L of sodium azide, 1-2ml / L of sulphuric acid, 300-400g / l of sodium persulfate and 300-400mmol / l of ethanolamine. The detection reagent provided by the invention is high in determination precision, strong in anti-interference capability and applicable to automatic rapid determination.

Owner:徐淼

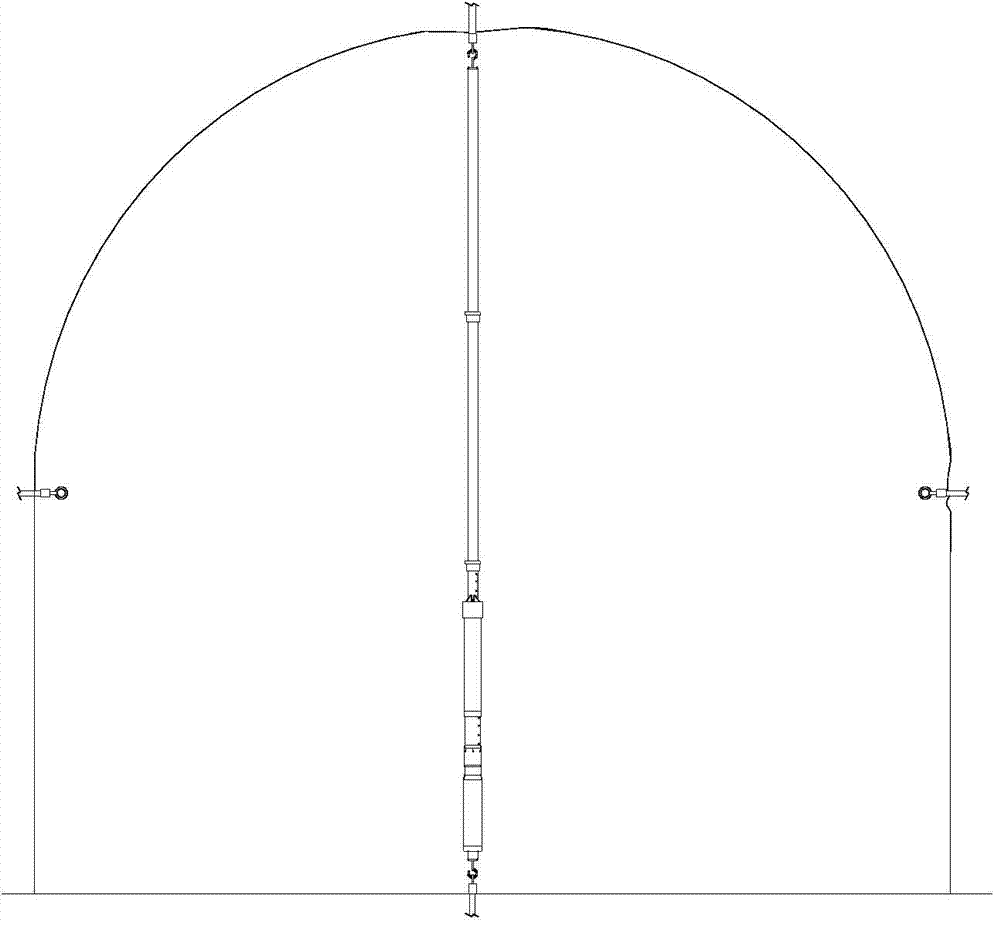

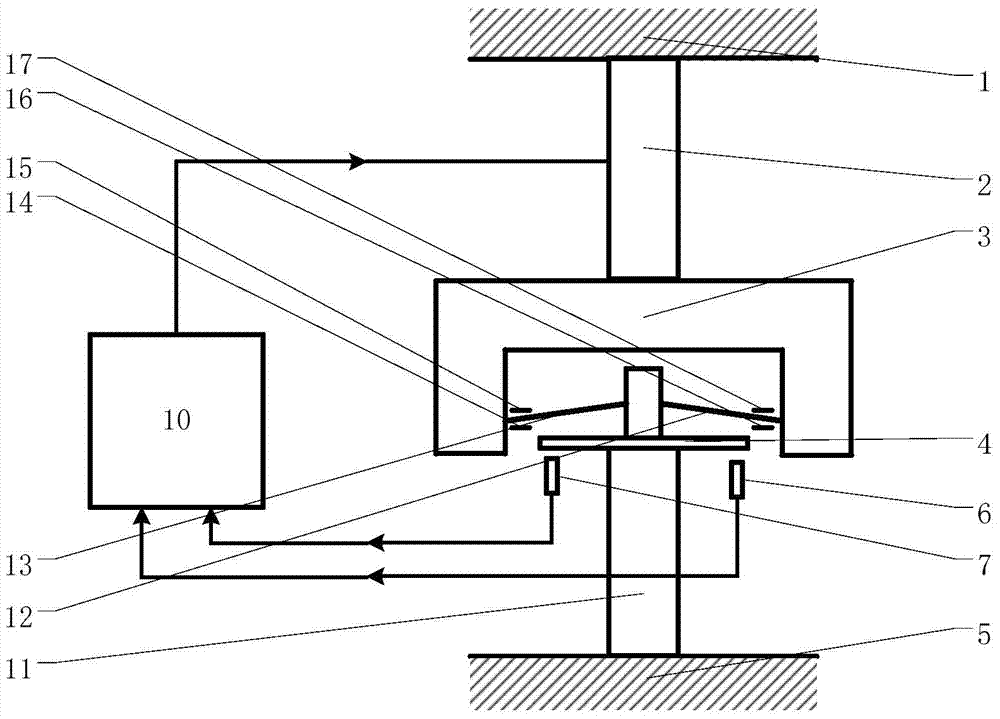

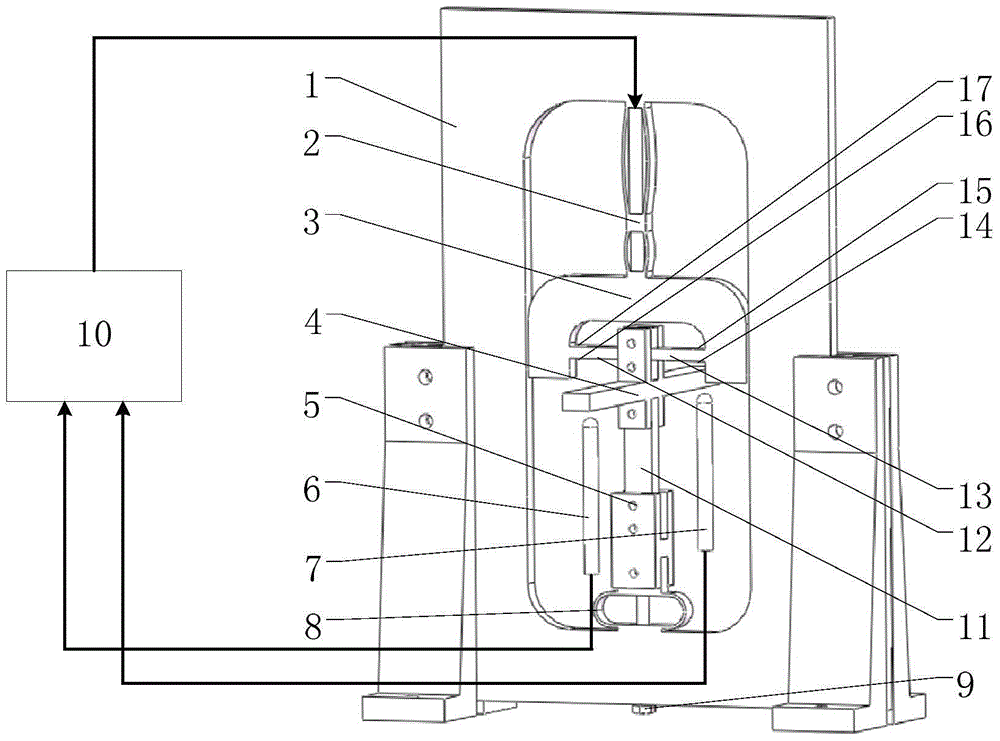

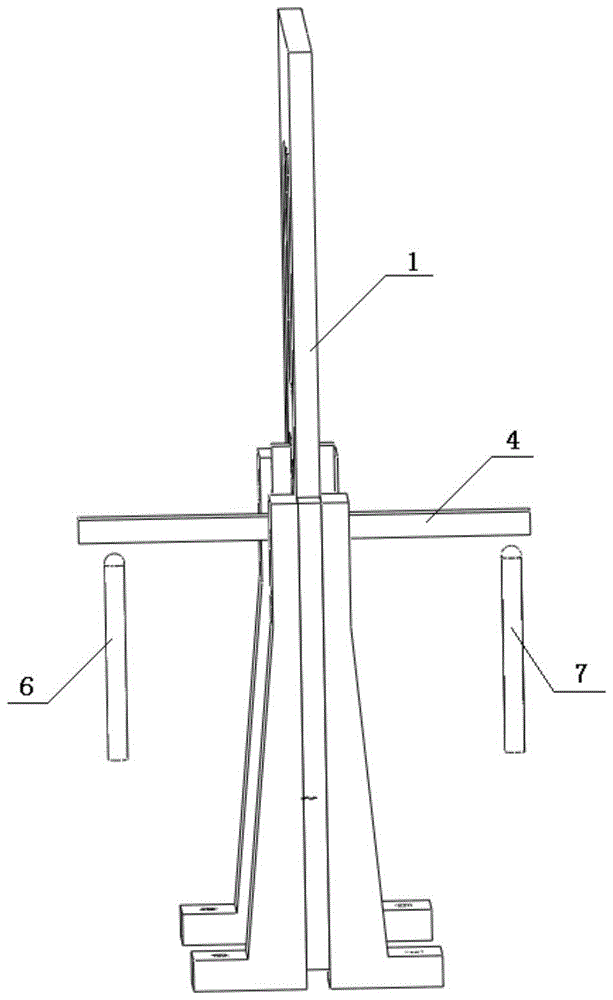

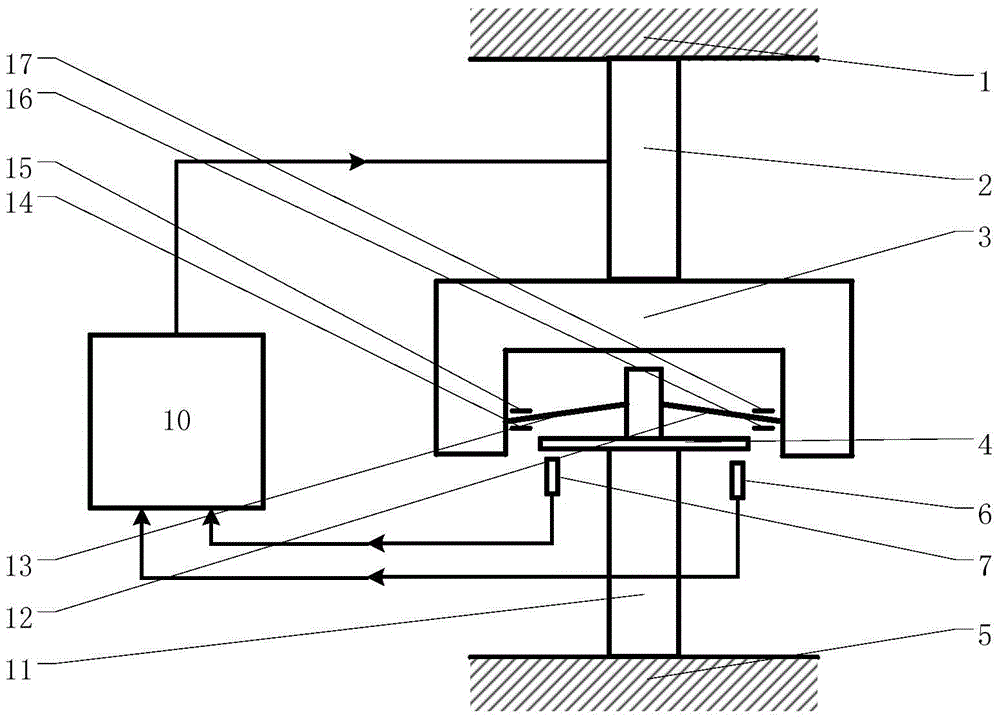

Piezoelectric actuator blocking force measuring device and method

ActiveCN104729776ASolve the problem that the thrust cannot be measuredHigh measurement precisionApparatus for force/torque/work measurementForce measurement by elastic gauge deformationPiezoelectric actuatorsDisplacement control

The invention provides a piezoelectric actuator blocking force measuring device and method. The system comprises an external frame, an actuating component arranged in the external frame, a force-sensitive component, a displacement control component, a piezoelectric actuator to be detected, an actuator connection component and a connection spring, wherein the force-sensitive component, the displacement control component, the piezoelectric actuator to be detected, the actuator connection component and the connection spring are sequentially connected to the lower end of the actuating component and arranged in the external frame. One end of the connection spring is connected with the external frame, and an adjusting bolt penetrates through the lower end of the external frame and is connected with the connection spring to be used for adjusting the position of the connection spring and being connected with the actuator connection component and fixed. A first displacement sensor and a second displacement sensor are located outside the external frame, arranged on the two sides of a displacement control component and connected with the input end of a controller. The output end of the controller is connected with the actuating component. The invention further discloses the measuring method. By means of the piezoelectric actuator blocking force measuring device and method, the problem that the blocking force of an existing piezoelectric actuator cannot be measured is solved, the blank of the measuring technology is filled, and the piezoelectric actuator blocking force measuring device and method have the advantages of being high in measuring precision, good in stability and convenient to use.

Owner:XI AN JIAOTONG UNIV

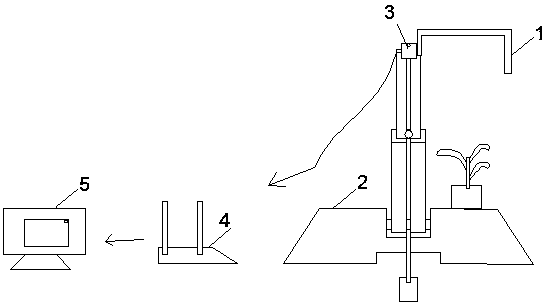

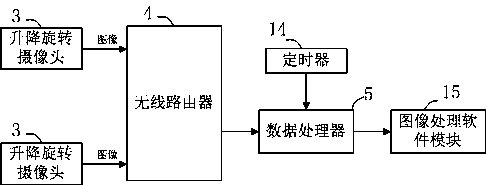

Closed type cultivation plant growth continuously monitoring simple system and monitoring method thereof

InactiveCN109708678AFully understand the growth statusHigh measurement precisionMeasurement apparatus componentsMechanical thickness measurementsWireless routerGrowth plant

The invention discloses a closed type cultivation plant growth continuously monitoring simple system which comprises an openable closed incubator and a monitored plant arranged therein, the openable closed incubator is internally provided with an adjustable monitoring device, the adjustable monitoring device comprises an elevating rotating camera and an elevation measuring device, the elevating rotating camera is adjustably connected onto a bearer along the height direction of the openable closed incubator, and is connected with a wireless router via a cable to send collected plant image datato a data processor, the top of a vertical adjusting device adjusts and fixes the elevating rotating camera via an angle adjusting support, the elevation measuring device is fixed in a predetermined height of the monitored plant, the zero graduation of the elevation measuring device is arranged in the bottom, namely, the graduation values is increased from bottom to top, and thus, the growth situation of the monitored plant can be measured in a visual manner.

Owner:南京迪天高新产业技术研究院有限公司

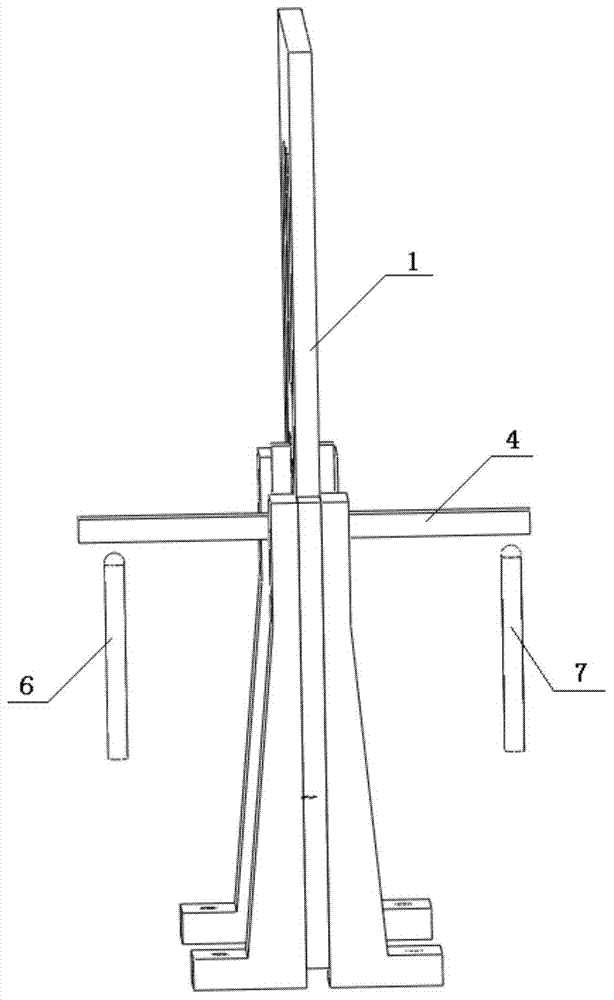

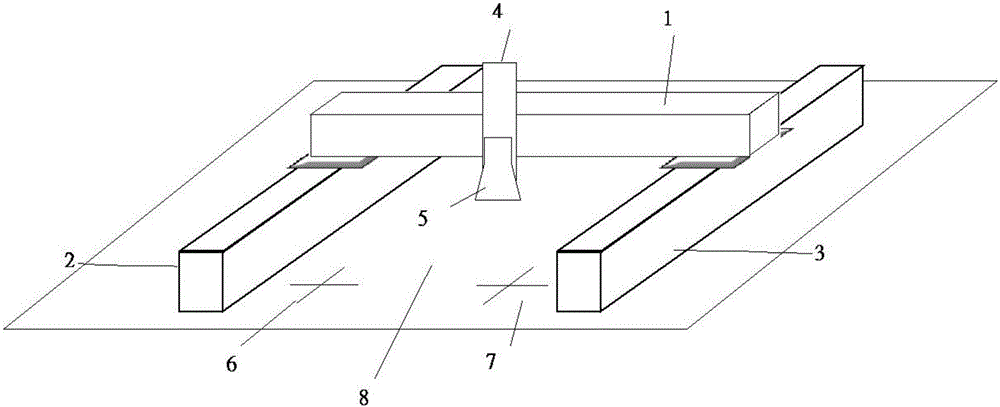

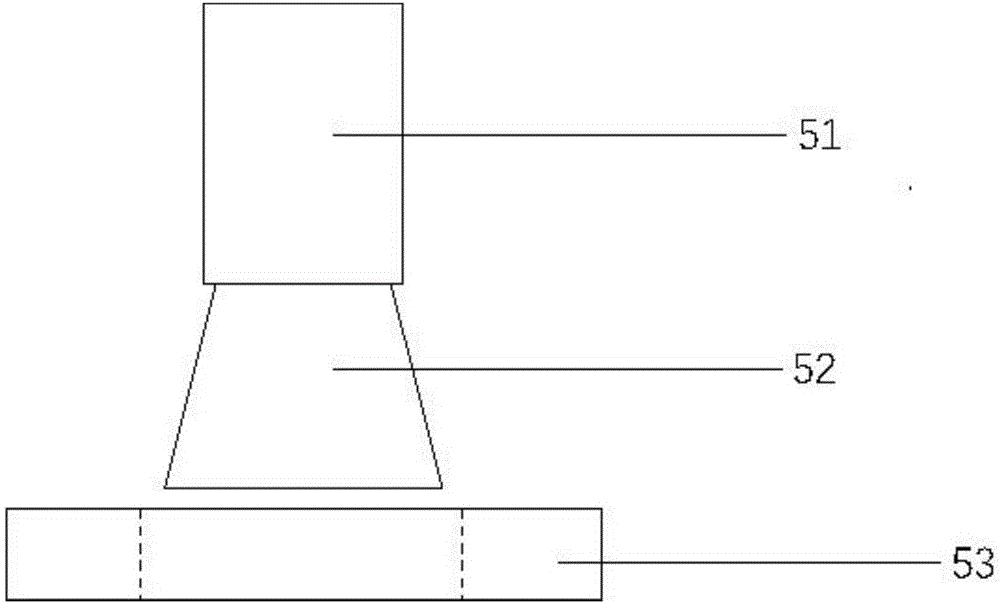

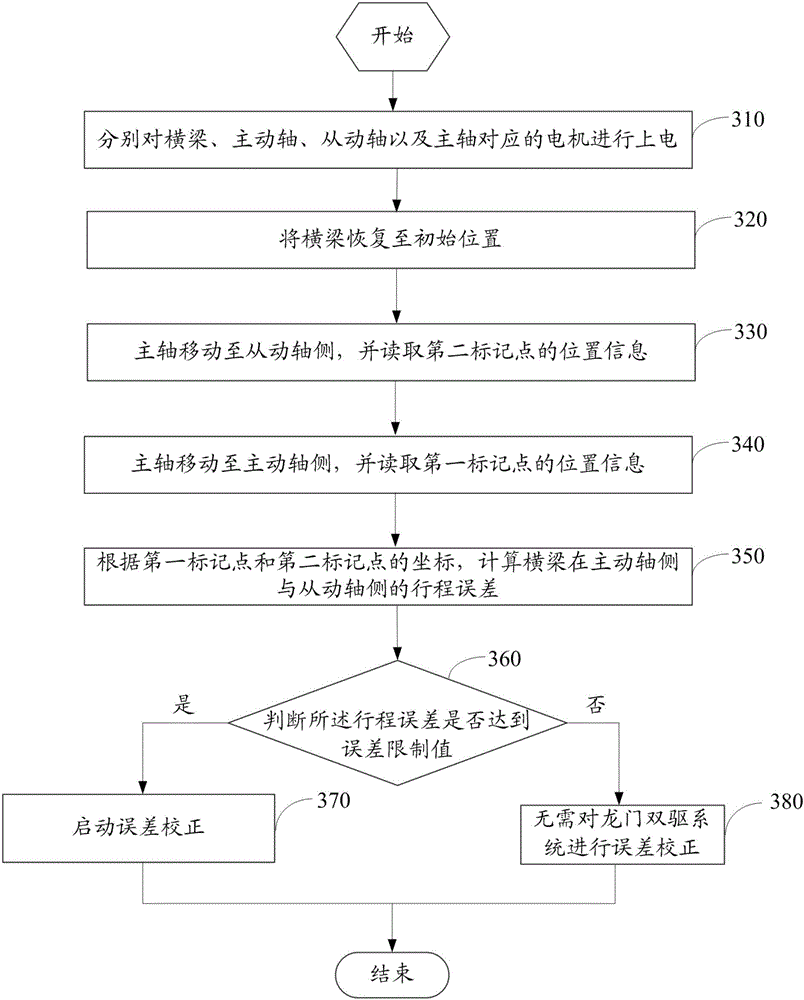

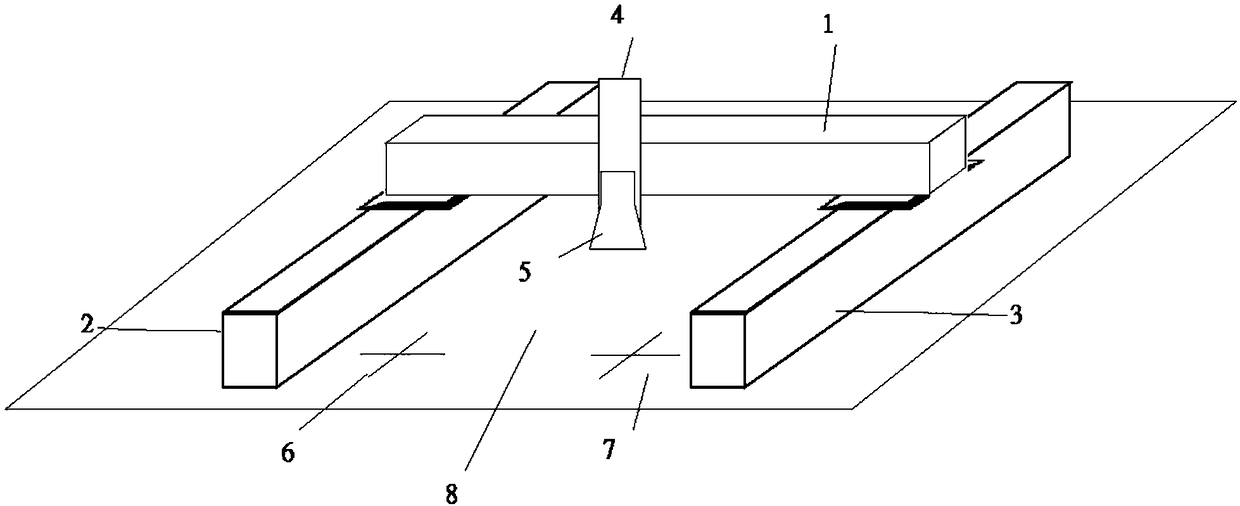

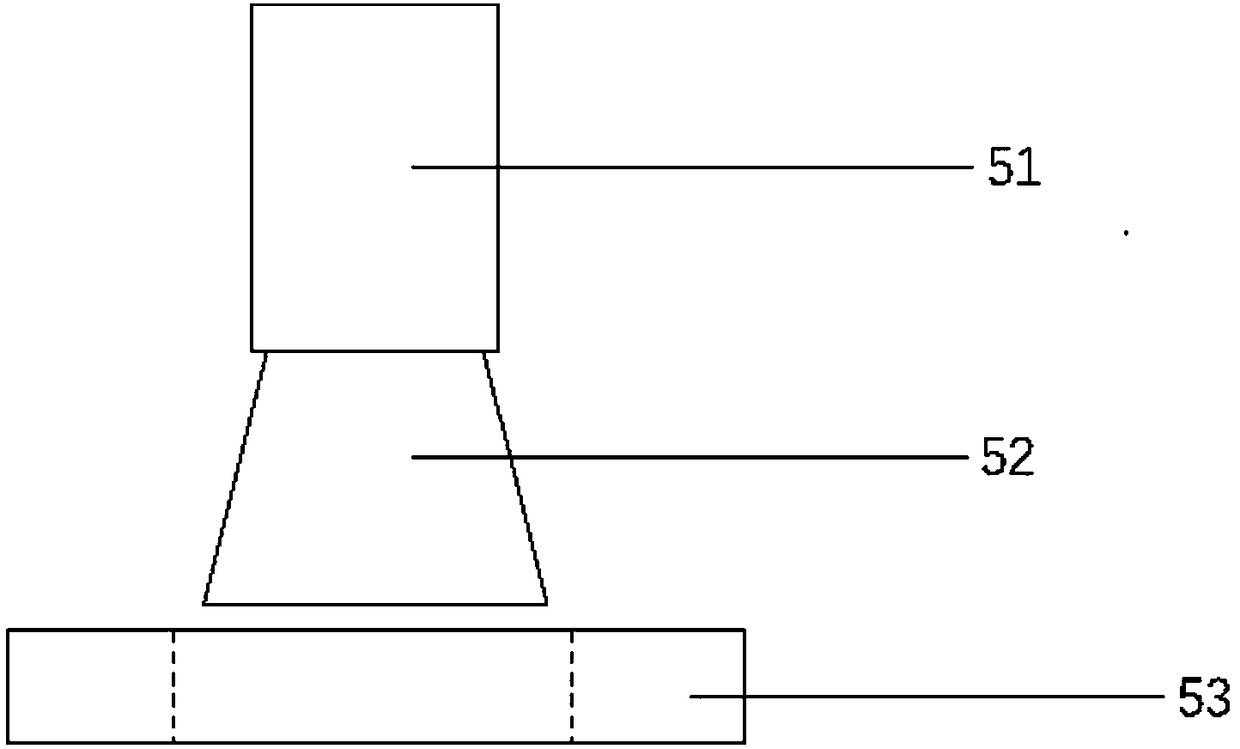

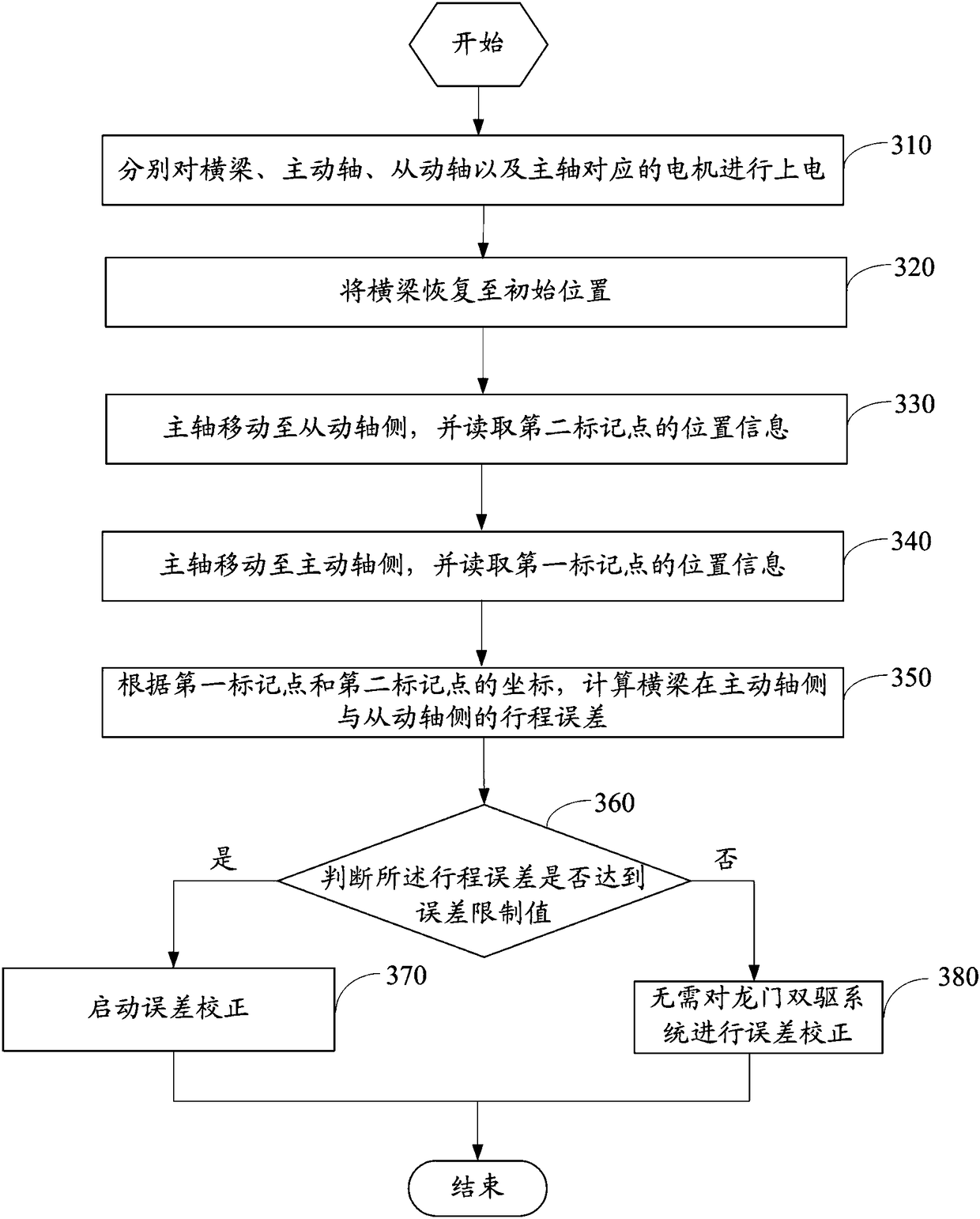

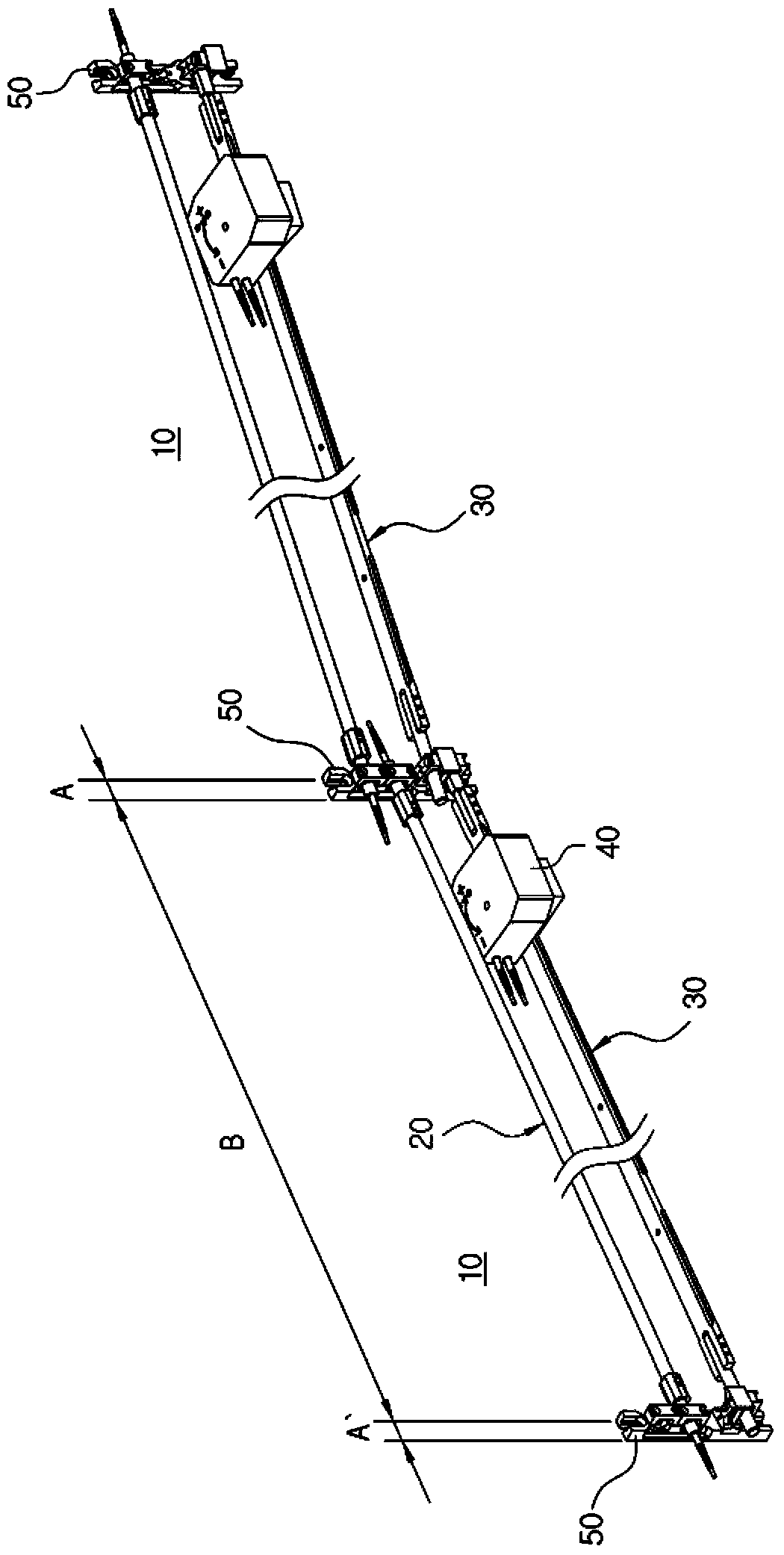

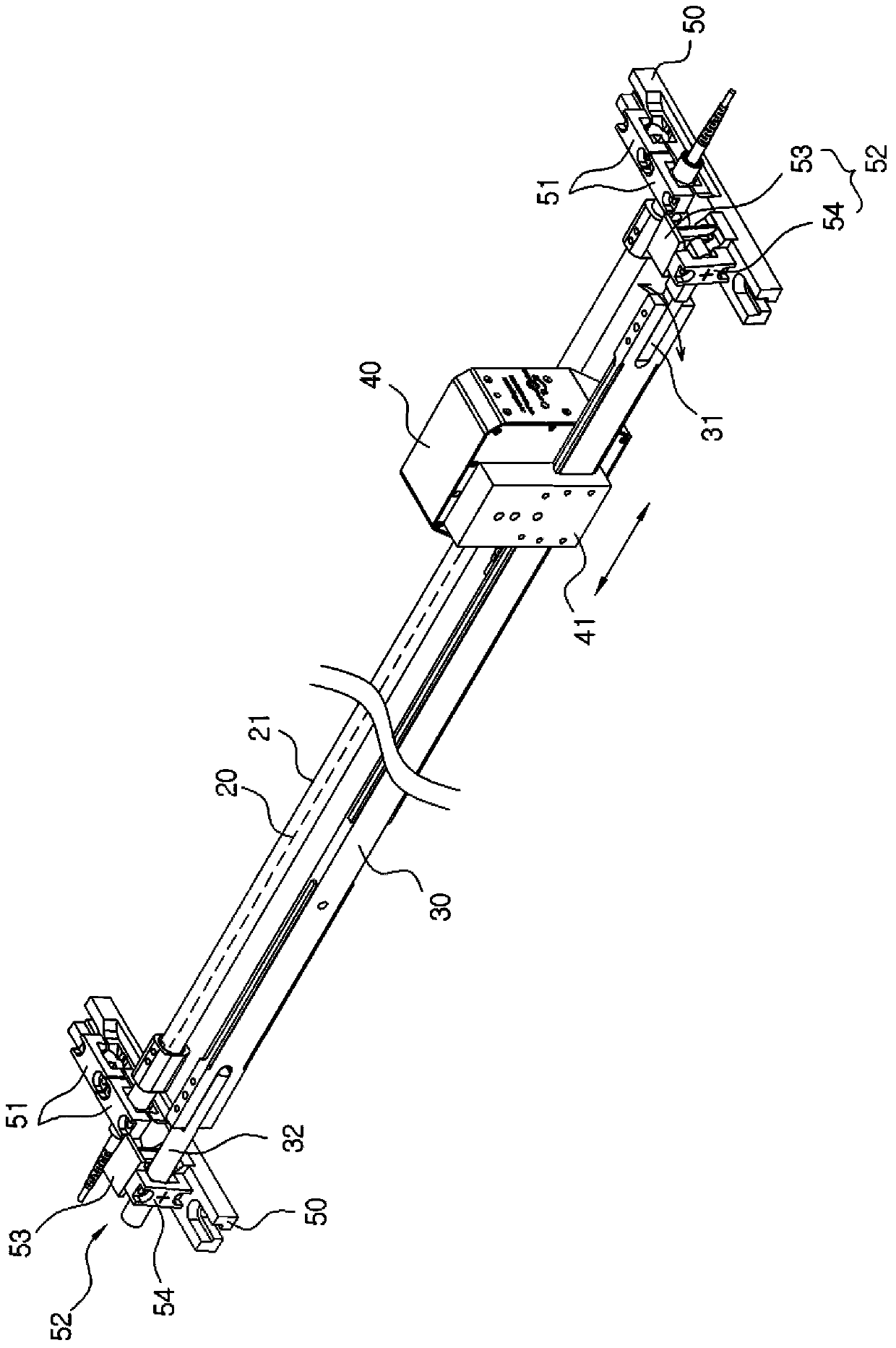

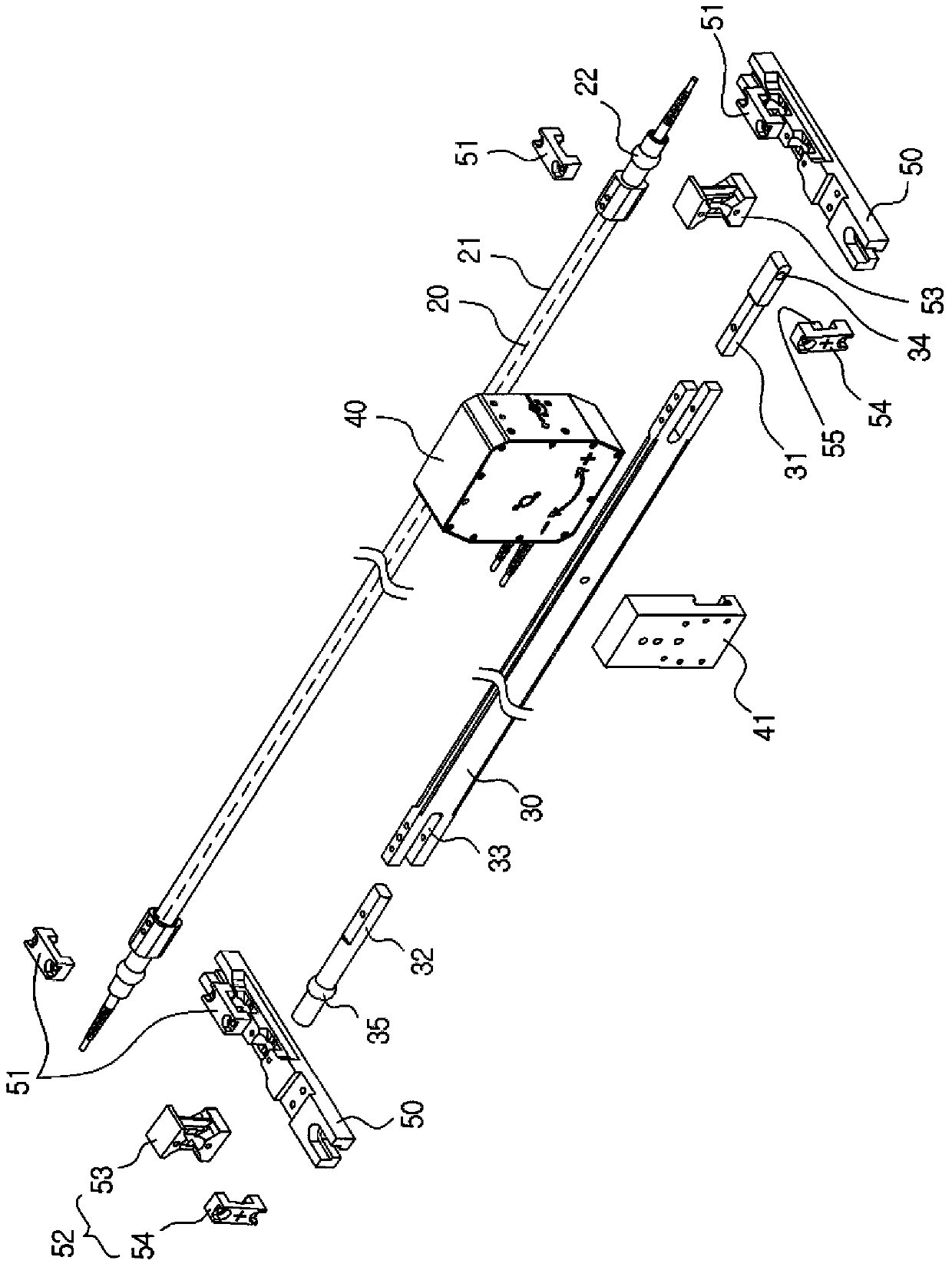

Gantry dual-driving system and error detection method thereof

ActiveCN106272369AHigh measurement precisionAvoiding the Difficulties of Double-sided Coupling ControlProgramme-controlled manipulatorDrive shaftRead through

The invention discloses a gantry dual-driving system and an error detection method thereof, and belongs to the technical field of automation control. The gantry dual-driving system comprises a cross beam, a driving shaft, a driven shaft, a main shaft, a first mark point and a second mark point, wherein the driving shaft and the driven shaft are parallel to each other, two ends of the cross beam are movably fixed on the main shaft and the driven shaft respectively, the first mark point and the second mark point are located between the driving shaft and the driven shaft, the main shaft is movably mounted on the cross beam, a visual system is arranged on the main shaft, and position information of the first mark point and that of the second mark point are read through the visual system respectively, so as to detect a journey error of the system. By virtue of mechanical characteristics of the dual gantry driving system per se, control complexity is reduced, not only is the characteristic of high measurement precision of the visual system exerted, but also the difficulty in double-side coupling control on the driving shaft and the driven shaft is avoided, and the gantry dual-driving system has a very high practical value.

Owner:易视智瞳科技(深圳)有限公司

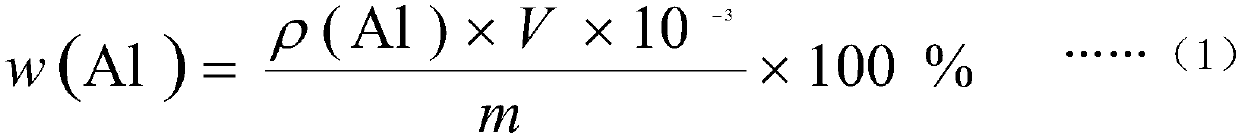

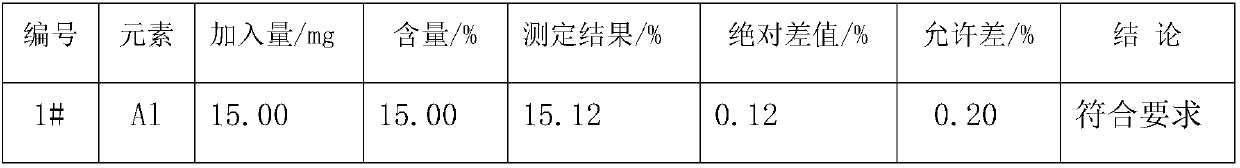

Method for measuring aluminium content in sherardizing agent

InactiveCN107703120AEasy to makeHigh measurement precisionPreparing sample for investigationAnalysis by thermal excitationDissolutionLength wave

The invention discloses a method for measuring the aluminium content in a sherardizing agent through inductively-coupled plasma atomic emission spectroscopy, and belongs to the technical field of chemical detection. The method comprises weighing of a sample material, dissolution pre-treatment, melt extraction, treatment of the sample material, dilution and constant volume setting, wavelength selection, preparation of an aluminium standard solution, preparation of a calibration curve, detection with inductively-coupled plasma atomic emission spectroscopy, and calculation of analysis results andprecision. According to the method, the dissolution pre-treatment is fast, the matching ability and anti-matrix interference of the prepared aluminium standard solution are great, the detection process is easy to master, and the detection result is accurate and reliable. According to the method, the test range of w(Al) is 15.00-40.00%.

Owner:CHANGAN AUTOMOBILE (GRP) CO LTD

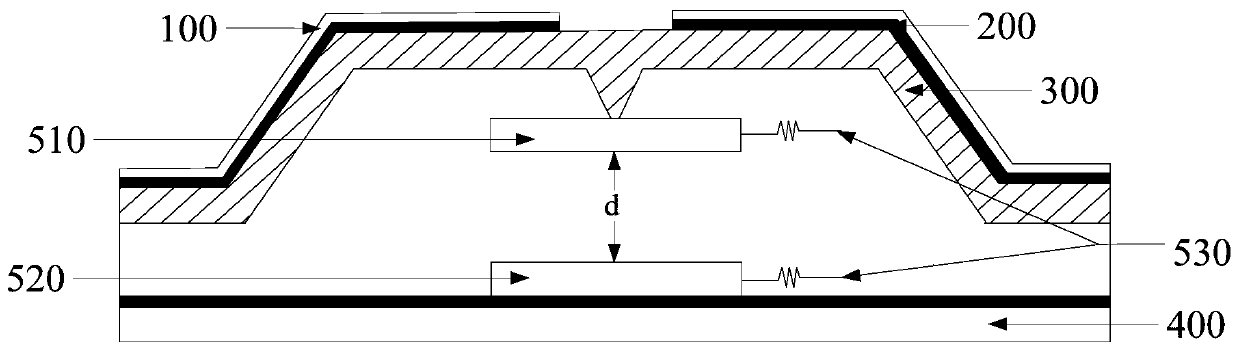

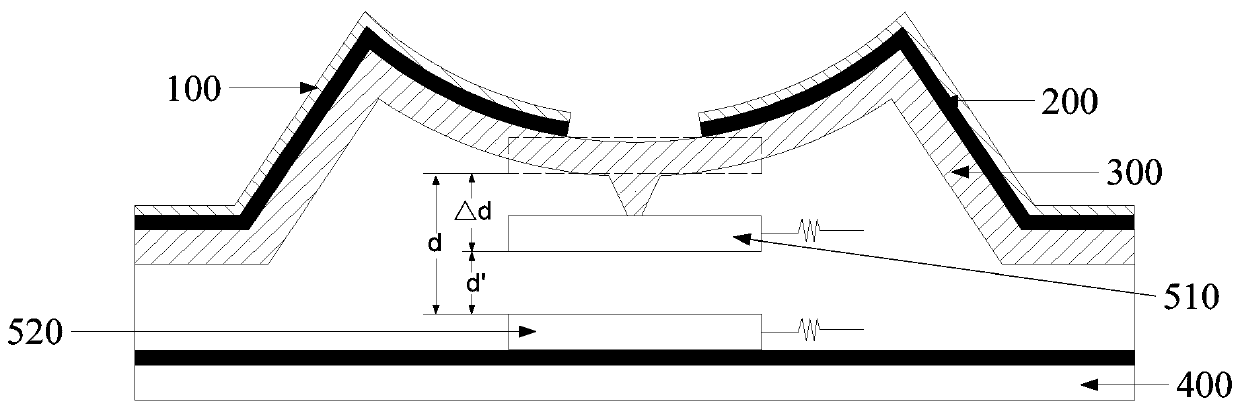

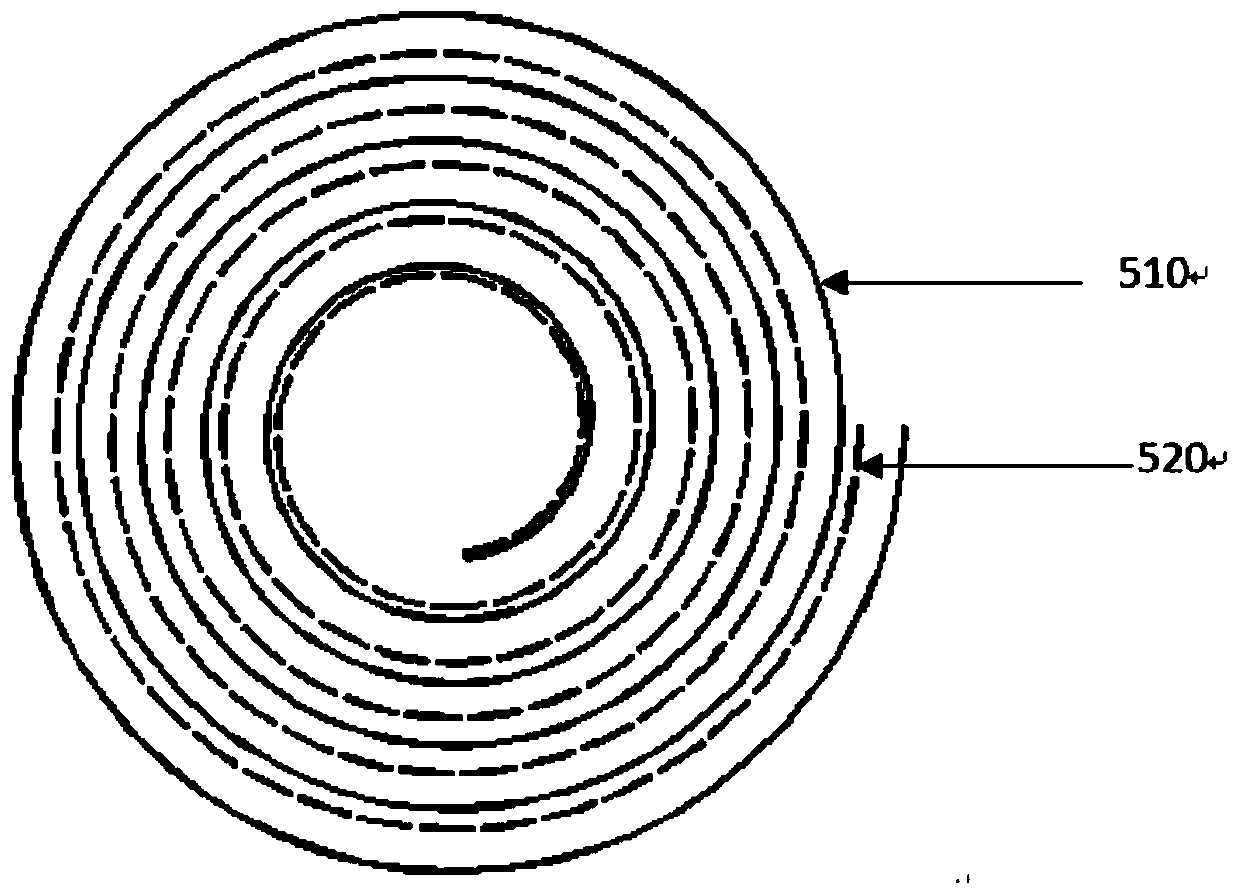

Capacitive hydrogen sensor

InactiveCN110596205AShort response timeHigh measurement precisionMaterial capacitanceCapacitanceEngineering

The invention provides a capacitive hydrogen sensor, which comprises a filtering protection layer, a hydrogen sensing layer, a deformation transmission layer, a capacitor and a substrate, wherein thefiltering protection layer is arranged outside the hydrogen sensing layer, and is used for protecting the hydrogen sensing layer from being impacted and filtering air dust particles; the hydrogen sensing layer is arranged between the filtering protection layer and the deformation transmission layer, and is used for deforming the structure thereof after absorbing a hydrogen gas; a part of the deformation transmission layer abuts against the capacitor, and is used for transmitting deformation of the hydrogen sensing layer to the capacitor; and the substrate is arranged at the bottom part of thecapacitor. When the hydrogen sensing layer is deformed after absorbing the hydrogen gas, the hydrogen sensing layer presses the deformation transmission layer, so that the deformation transmission layer is bent to push the capacitor downwards, and the capacitance value of the capacitor is changed. The capacitive hydrogen sensor has the beneficial effects that the response time of the sensor is remarkably shortened, and the measurement precision is improved.

Owner:安徽伯华氢能源科技有限公司

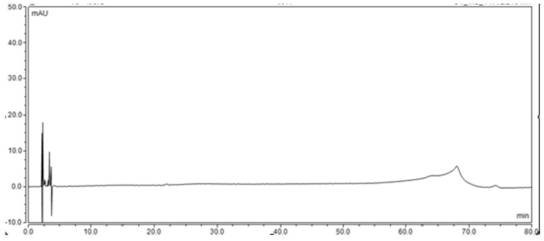

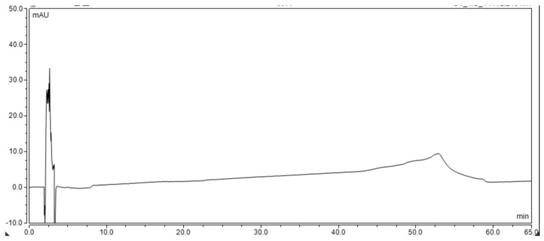

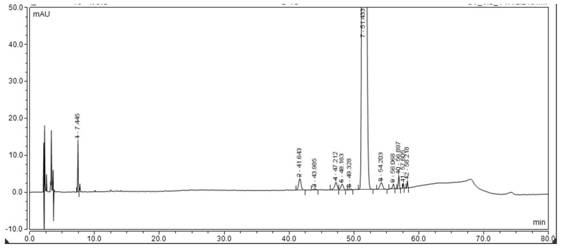

Detection method for related substances in ganirelix acetate injection

The invention discloses a detection method for related substances in a ganirelix acetate injection, which has the advantages of quickness, simplicity, convenience, high sensitivity, accuracy and reliability and is suitable for separating and determining the related substances in the ganirelix acetate injection. According to the method, the comprehensive influence of an analysis column, a mobile phase, a gradient elution program, a flow rate and a column temperature on separation and detection is comprehensively considered, so that the detection result is optimized, and the method has the advantages of rapidness, simplicity, convenience, high sensitivity, accuracy and reliability, and is suitable for separating and determining related substances of the ganirelix acetate injection.

Owner:南京诺卡医药技术有限公司

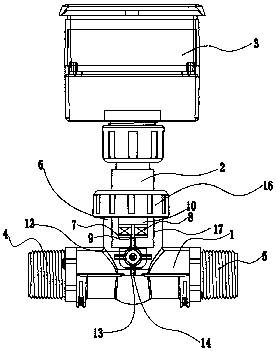

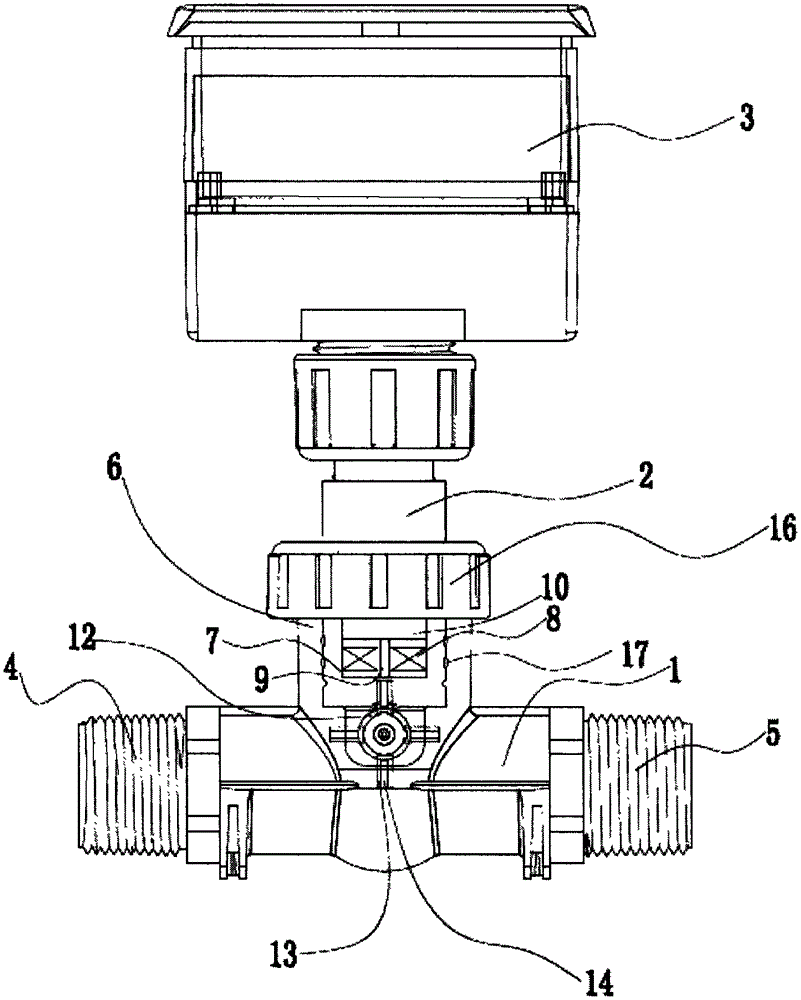

Simple flowmeter

InactiveCN107727173ASimple structureHigh speedVolume/mass flow by electric/magnetic effectsImpellerElectricity

The invention discloses a simple flow meter used in the fields of petroleum, chemical industry, etc., which comprises a pipe body, an impeller assembly and a display controller. The pipe body is provided with a liquid inlet, a liquid outlet and a measuring pipeline. The display controller includes The casing and the control module, the impeller assembly includes an impeller seat and a blade assembly, one end of the impeller seat extends into the measuring pipe, and the other end is fixed on the casing, a preamplifier is arranged in the impeller seat, and an induction coil is arranged in the preamplifier, and A permanent magnet is embedded in the center of the induction coil, and an amplifier electrically connected to the control module is provided at the upper end of the induction coil, and the blade assembly includes a blade base, two or more blades on the blade base and metal rods on the blades; The two ends of the blade seat are connected to the impeller seat through bearings; the principle of the magnetic flux change in the induction coil caused by cutting the magnetic field line with the metal rod is used, and then the magnetic flux is amplified and displayed, so as to achieve simple overall structure, fast speed and high measurement precision.

Owner:CHANGZHOU CHENTONG TELECOMM EQUIP FACTORY

Total bile acid detection reagent

InactiveCN106896101AGood colorRapid responseMaterial analysis by observing effect on chemical indicatorSterolPyridine-N-oxide

The invention relates to a total bile acid detection reagent. The detection reagent is composed of the following components: 6-8wt% of a preservative, 30-40mmol / L of sodium pyruvate, 30-40g / L of glycinate buffer solution, 8-10g / L of dextran sulfate, 2-3g / L of 2-hydroxy pyridine-N-oxide, 5-8g / L of a stabilizer, 30-40mmol / L of phosphatic buffer solution, 6000-7000u / L of diaphorase, 3-4g / L of sodium azide, 4-5mmol / L of a chemical oxidant, 2-3wt% of a free-drying protective agent, 30-40mmol / L of NaCl, 6-8KU / L of 3alpha-hydrocarbon sterol dehydrogenase, 3-10g / L of human serum albumin, 6-8mmol / L of an oxidizing auxiliary enzyme I, 12-15g / L of a reduced coenzyme I and 2-3g / L of nitrotetrazolium blue. The detection reagent provided by the invention is high in determination precision, strong in anti-interference capability, good in stability, long in retention period and easy to store and transport.

Owner:徐淼

A Simple Flow Meter

InactiveCN106813723ASimple structureHigh speedVolume/mass flow measurementChemical industryEngineering

The invention discloses a simple flow meter used in the fields of petroleum, chemical industry, etc., which comprises a pipe body, an impeller assembly and a display controller. The pipe body is provided with a liquid inlet, a liquid outlet and a measuring pipeline. The display controller includes The casing and the control module, the impeller assembly includes an impeller seat and a blade assembly, one end of the impeller seat extends into the measuring pipe, and the other end is fixed on the casing, a preamplifier is arranged in the impeller seat, and an induction coil is arranged in the preamplifier, and A permanent magnet is embedded in the center of the induction coil, an amplifier electrically connected to the control module is provided at the upper end of the induction coil, and the blade assembly includes a blade base, two or more blades located on the blade base, and a metal rod located on the blade; The two ends of the blade seat are connected to the impeller seat through bearings; the principle of the magnetic flux change in the induction coil caused by cutting the magnetic field line with the metal rod is used, and then the magnetic flux is amplified and displayed, so as to achieve simple overall structure, fast speed and high measurement precision.

Owner:CHANGZHOU CHENTONG TELECOMM EQUIP FACTORY

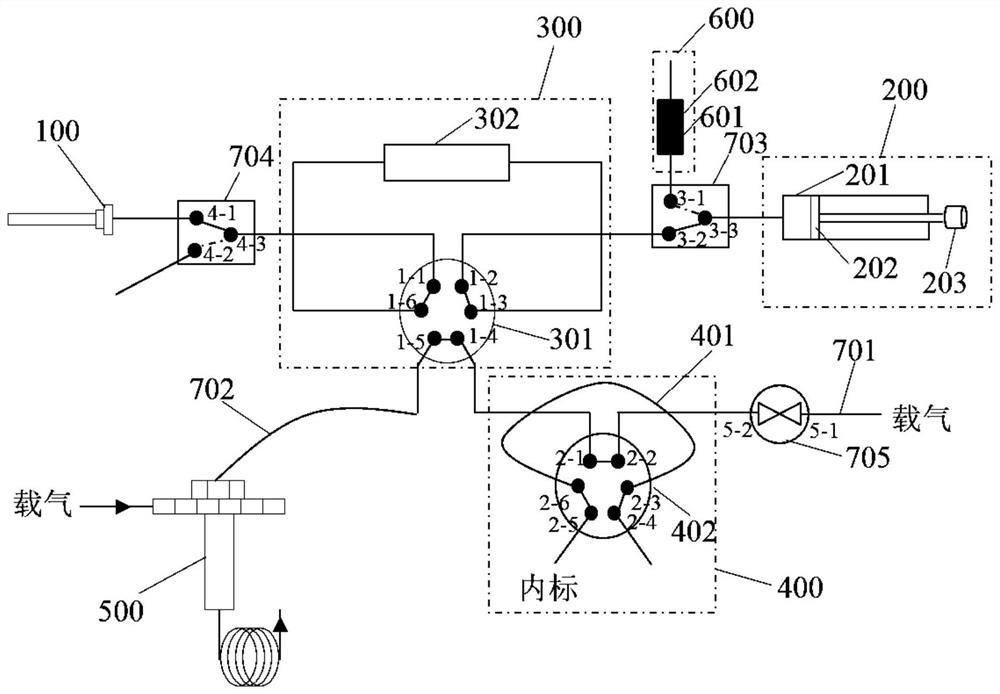

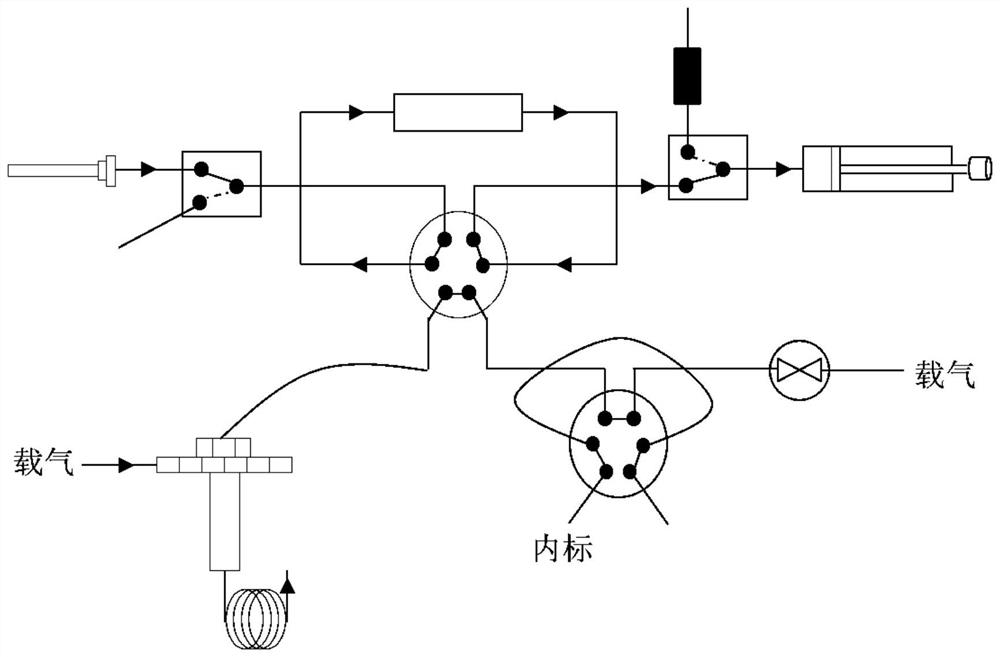

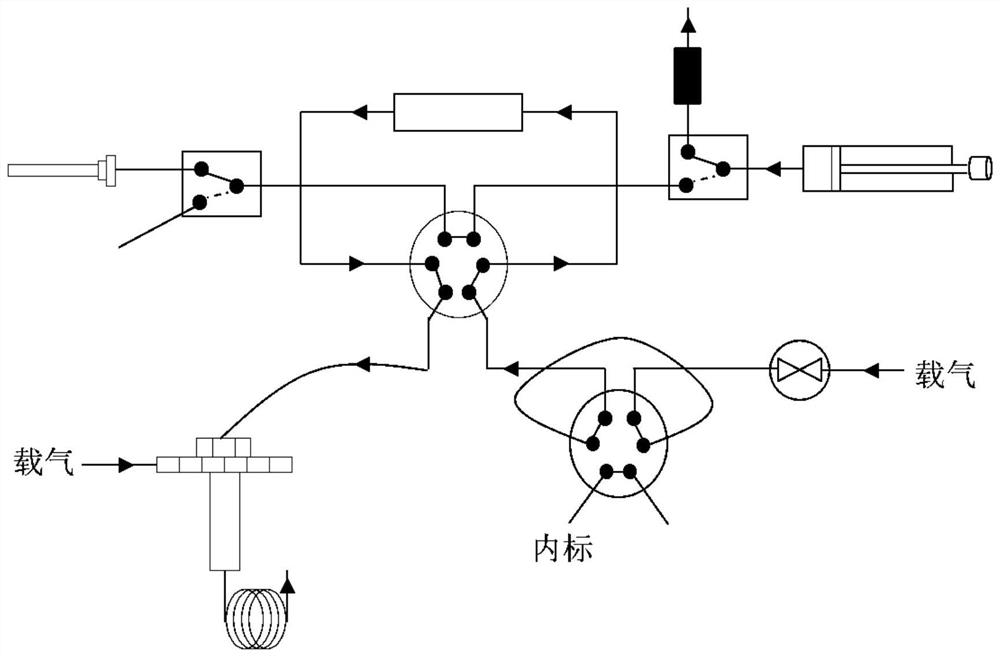

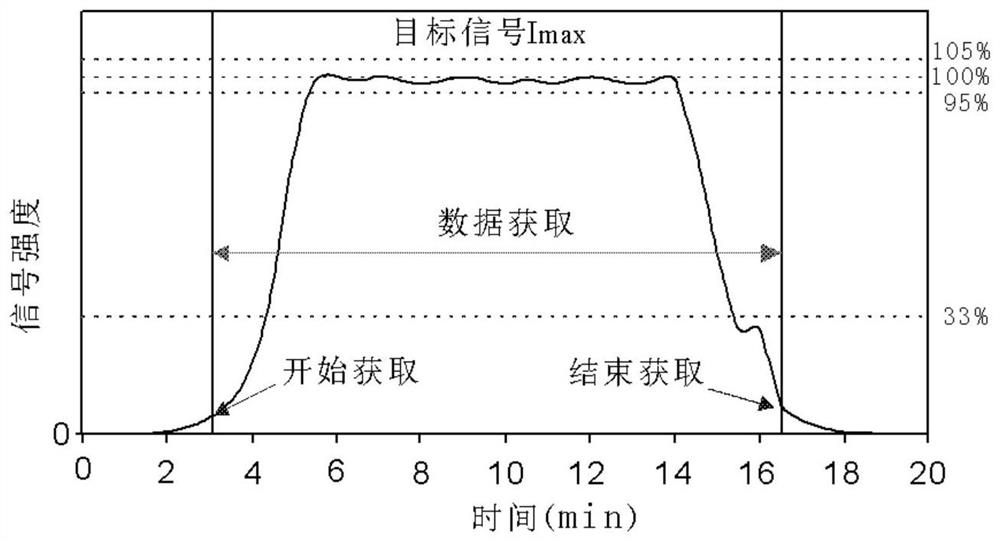

Online analysis and detection device and method for heated cigarette smoke

PendingCN113970600AReduce usageHigh measurement precisionComponent separationFlue gasProcess engineering

The invention discloses an on-line analysis and detection device and method for heated cigarette smoke. The device comprises a cigarette holder, a cigarette smoking module, an on-line sampling module, an on-line internal standard introduction module, an on-line smoke analysis module, a flow path system and a control module. The cigarette holder, the cigarette smoking module, the on-line introduction internal standard module and the on-line smoke analysis module are communicated with the on-line sampling module through the flow path system, and the on-line introduction internal standard module is further used for being communicated with external carrier gas; the on-line sampling module is used for collecting a smoke sample and introducing the smoke sample into the on-line smoke analysis module; the on-line internal standard introduction module is used for collecting an internal standard gas sample and introducing the internal standard gas sample into the on-line flue gas analysis module; and the on-line smoke analysis module is used for receiving the smoke sample and the internal standard gas sample to carry out smoke on-line analysis and detection. Internal standard gas is quantitatively introduced into the on-line flue gas analysis module through the on-line internal standard introduction module, so that the sample introduction amount can be ensured to be accurate, and the detection precision is improved; the smoke sample does not need to be subjected to any sample pretreatment, and simplicity, convenience and high efficiency are achieved.

Owner:CHINA TOBACCO HUNAN INDAL CORP

Device and method for measuring cloud point pressure and density of supercritical CO2 microemulsion system

InactiveCN105890839BSimple structureImprove sealingFluid pressure measurementMaterial resistanceElectrical resistance and conductanceWater storage tank

The invention discloses an apparatus and method for measuring the cloud point pressure and density of a supercritical CO2 microemulsion system. A magneton is arranged in a visual container, an electronic stirrer is arranged under the visual container, and the upper portion of the visual container is connected with a five-way valve. A quartz window is arranged on each of two parallel sides on the lower portion of the visual container, a light source is arranged on the outer side of one quartz window, and an opaque chamber is arranged on the outer side of the other quartz window. A photoresistor connected with a universal meter is arranged in the opaque chamber, and a CO2 gas cylinder is connected with the five-way valve. A second pressure transducer is connected to the five-way valve, one end of an intermediate container is connected to the five-way valve, and the other end of the intermediate container is connected with a three-way valve. A gas tank is connected with the five-way valve, one end of a high-pressure plunger pump is connected to the three-way valve, and the other end of the high-pressure plunger pump is connected with a water storage tank. A liquid volume metering device is connected with the three-way valve. The cloud point pressure of a supercritical CO2 microemulsion system and the density of the supercritical CO2 microemulsion system under the cloud point pressure can be obtained under same condition, the influence of minimal difference in parallel experiment processes can be minimized, and important basic data for designing construction scheme of an oil field can be provided.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

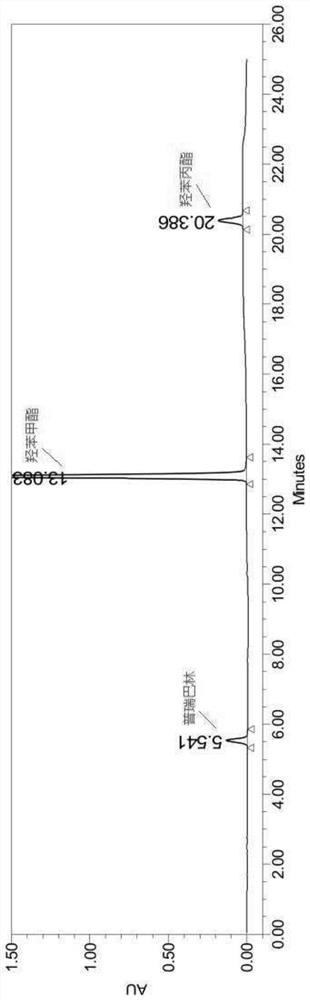

Method for simultaneously determining contents of pregabalin and hydroxybenzene ester bacteriostatic agent

ActiveCN111855828AGood peak shapeHigh theoretical plate numberComponent separationPregabalinSilica column

The invention belongs to the field of medicines, and relates to a method for determining the content of pregabalin and a hydroxybenzene ester bacteriostatic agent. Specifically, the invention relatesto the method for simultaneously determining the pregabalin content and the hydroxybenzene ester bacteriostatic agent content in a pregabalin oral solution. The method is an HPLC method, and HPLC conditions are as follows: a chromatographic column is an octadecylsilane chemically bonded silica column; the column temperature is 20 to 40 DEG C; the mobile phase A is a 20 to 30 mmol / L monopotassium phosphate solution, and the pH value is 6.2 to 7.0; the mobile phase B is methanol; the flow rate is 0.5 to 1.5 mL / min; the sample size is 10 to 30 [mu] L; and the detection wavelength 210 nm. The method disclosed by the invention is good in specificity, high in sensitivity, good in repeatability and high in accuracy, and can be used for controlling the quality of the pregabalin oral solution.

Owner:ACADEMY OF MILITARY MEDICAL SCI

A rhenium strip processing device and method

ActiveCN109632927BRealize the function of degassingRealize the function of carburizing treatmentMaterial analysis by electric/magnetic meansEngineeringMechanical engineering

Owner:CHINA INSTITUTE OF ATOMIC ENERGY

Measuring device and method for thrust force of piezoelectric actuator

ActiveCN104729776BSolve the problem that the thrust cannot be measuredHigh measurement precisionApparatus for force/torque/work measurementForce measurement by elastic gauge deformationPiezoelectric actuatorsDisplacement control

Owner:XI AN JIAOTONG UNIV

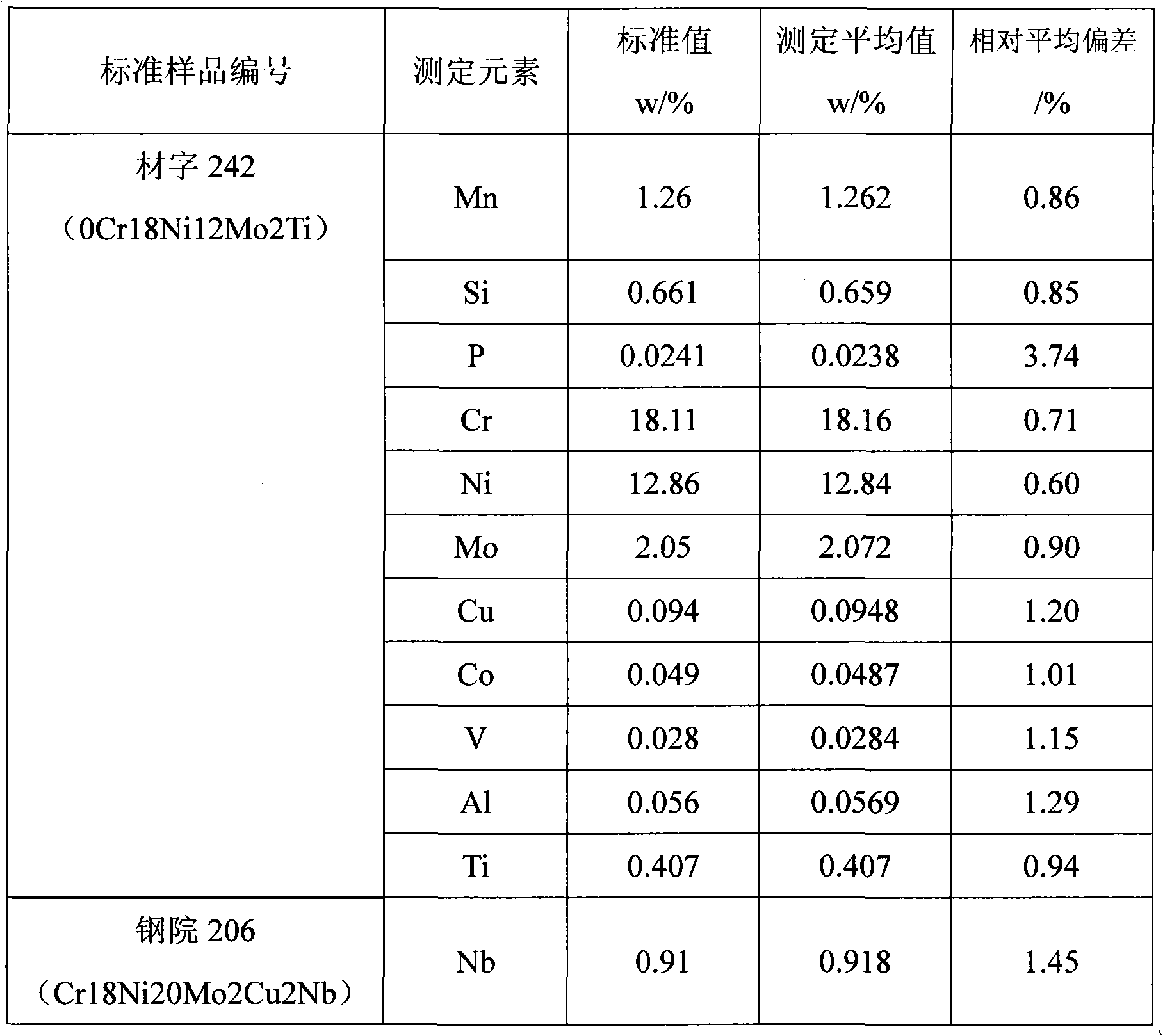

Method for fast and effectively improving measurement accuracy of 12 elemental composition in stainless steel

InactiveCN101430284BEfficient determinationMicro emissionAnalysis by thermal excitationElemental compositionManganese

Owner:SHANGHAI ELECTRIC POWER GENERATION EQUIPMENT CO LTD

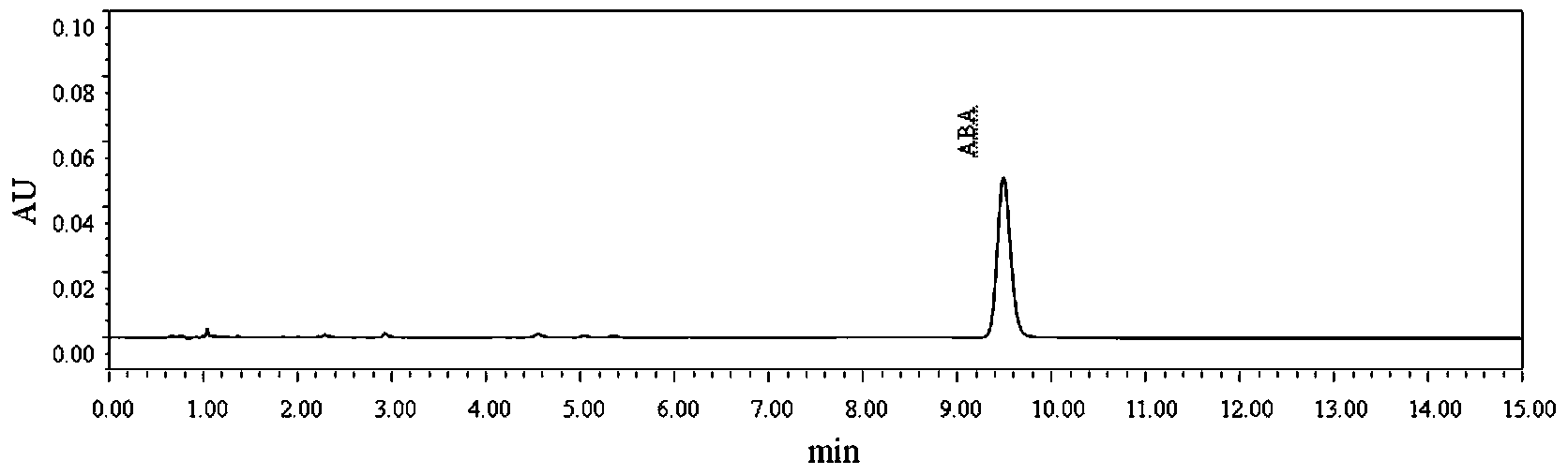

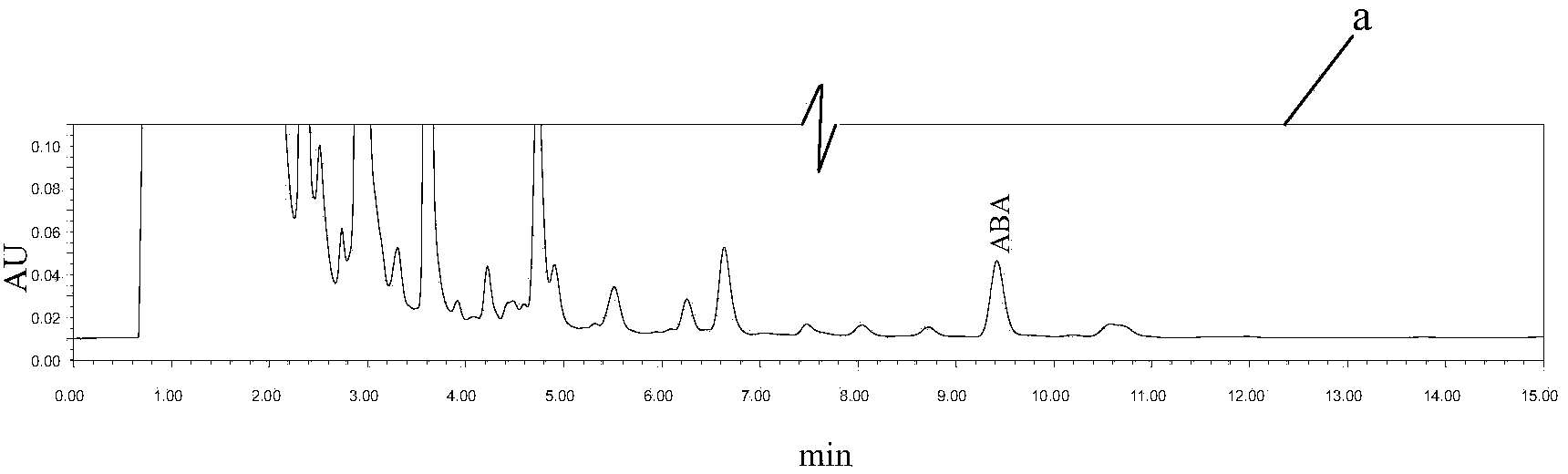

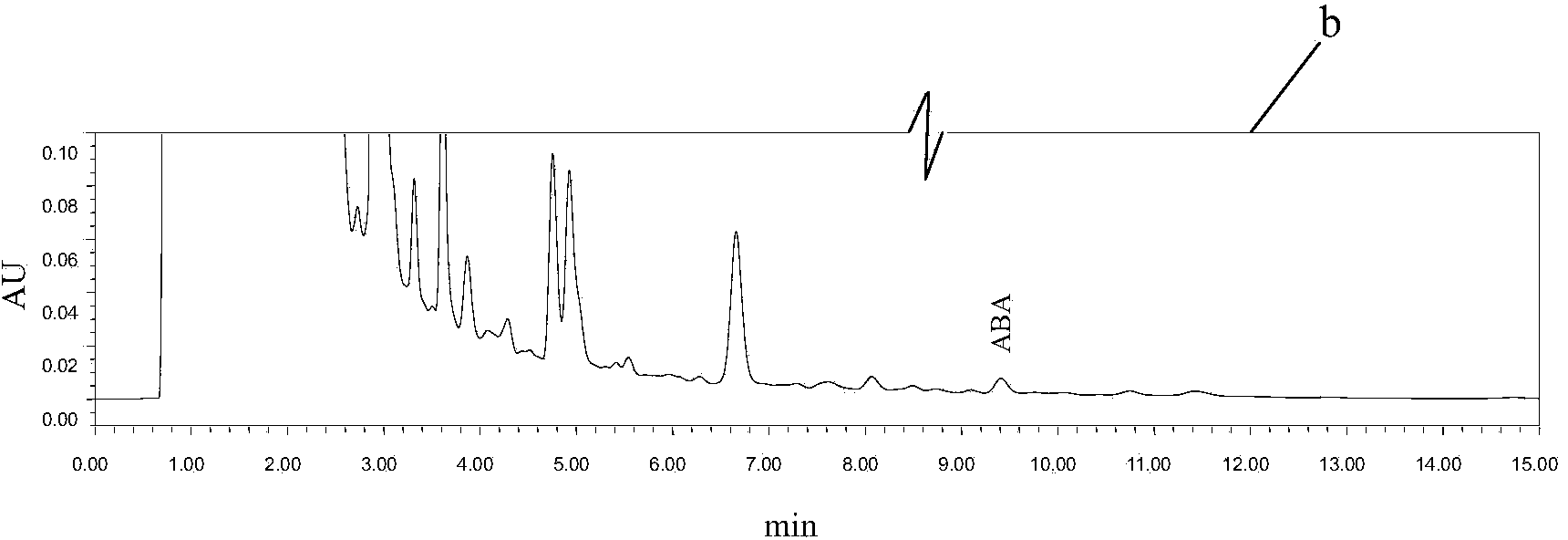

Method for extracting and measuring ABA (abscisic acid) of strawberry

The invention provides a method for extracting and measuring ABA of a strawberry. The method comprises the steps as follows: a mixed liquid of methyl alcohol, ethyl acetate and formic acid in a volume ratio of 50: 50:1 is taken as an extraction solvent, an ABA component in strawberry fruit pulp can be extracted in shorter time, residue is removed through suction filtration, an obtained filter liquor is decompressed and rotationally steamed to be dried at the temperature of 35 DEG C, and then, a flowing phase of an ultra-high performance liquid chromatography is added for dissolution, a solution is collected, and an extracting solution of strawberry ABA is obtained after filtered by a 0.22 mu m filter membrane; and the obtained extracting solution is injected into an ultra-high performance liquid chromatographic instrument under the set chromatographic condition for measurement and analysis. The method has the characteristics of high extraction speed, measurement accuracy and sensitivity and good repeatability, further, a measurement result is accurate and reliable, and the dosage of a reagent is small, so that the measurement speed is greatly increased, and the solvent consumption is reduced.

Owner:建瓯市梦园农业发展有限公司

Gantry Double Drive System and Its Error Detection Method

ActiveCN106272369BHigh measurement precisionAvoiding the Difficulties of Double-sided Coupling ControlProgramme-controlled manipulatorDrive shaftEngineering

The invention discloses a gantry dual-driving system and an error detection method thereof, and belongs to the technical field of automation control. The gantry dual-driving system comprises a cross beam, a driving shaft, a driven shaft, a main shaft, a first mark point and a second mark point, wherein the driving shaft and the driven shaft are parallel to each other, two ends of the cross beam are movably fixed on the main shaft and the driven shaft respectively, the first mark point and the second mark point are located between the driving shaft and the driven shaft, the main shaft is movably mounted on the cross beam, a visual system is arranged on the main shaft, and position information of the first mark point and that of the second mark point are read through the visual system respectively, so as to detect a journey error of the system. By virtue of mechanical characteristics of the dual gantry driving system per se, control complexity is reduced, not only is the characteristic of high measurement precision of the visual system exerted, but also the difficulty in double-side coupling control on the driving shaft and the driven shaft is avoided, and the gantry dual-driving system has a very high practical value.

Owner:易视智瞳科技(深圳)有限公司

Device for Measuring Convergence Displacement and Top Subsidence Using Fiber Bragg Grating Sensor

ActiveCN106482642BAccurate measurementExcellent measurement resolutionForce measurementHeight/levelling measurementFiberEngineering

The invention relates to a device for measuring convergence displacement and top settlement using fiber grating sensors, which includes: a plurality of unit fiber grating sensor modules. The plurality of unit fiber grating sensor modules have a preset length and are continuously connected for use; The unit fiber Bragg grating sensor module includes: a fiber Bragg grating strain sensor, which is installed inside the protective tube for detecting length changes; a setting component, which is arranged side by side on one side of the above-mentioned protection tube; and a fiber Bragg grating angular displacement sensor, which is arranged on the above-mentioned setting component. For measuring angular displacement, the present invention continuously measures two-dimensional or three-dimensional convergence displacement and top settlement, thereby achieving the following effects: multiple unit fiber grating sensor modules can be continuously installed on the measurement object to measure cross-sectional deformation based on The movement distance and angular displacement of the coordinate points can be accurately measured, so that the convergence displacement and top settlement can be accurately measured.

Owner:FBG KOREA INC

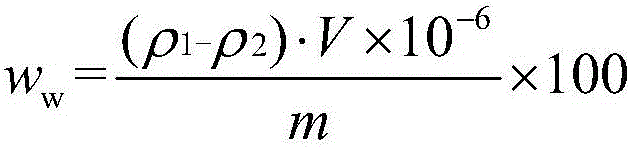

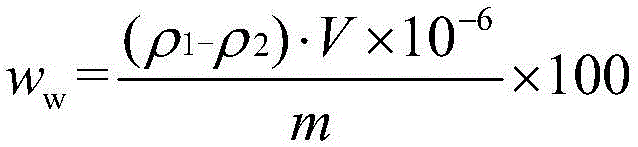

Analysis method for B impurity elements in electronic wet chemicals

InactiveCN105606591AGood linear relationshipAccurate measurementAnalysis by thermal excitationAnalysis methodMeasurement precision

The invention discloses an analysis method for B impurity elements in electronic wet chemicals. An inductively coupled plasma atomic emission spectrometer is adopted for analysis, the method is characterized in that a sampling system of the inductively coupled plasma atomic emission spectrometer is washed with high-purity inorganic acid for 48-72 h before sampling after startup and then washed with ultrapure water for 6-18 h without midway shutdown. The method can eliminate interference caused by the B elements in a detection background, and is accurate and quick in measurement, high in measurement precision, low in detection limit and wide in linear range.

Owner:ZHEJIANG KAISN FLUOROCHEM

Conical twin-screw extruder PVC high calcium filling precision metering feeding equipment

The invention relates to a precise polyvinyl chloride (PVC) high-calcium fill metering and feeding device of a conical twin-screw extruder. The device comprises a storage device, a feeding device and a stirring device, wherein the storage device consists of a feeding hopper and a hopper cover arranged at the upper part of the feeding hopper; the feeding device comprises a feeding barrel, a driving motor, a motor connecting plate, a motor connecting body, a feeding screw rod, a first bearing seat, a deep groove ball bearing, a bearing check ring, a felt ring and a bearing cover; the stirring device comprises a stirring body, a stirring shaft, a second bearing seat, a shaft sleeve, a sprocket chain and a sprocket cover. Compared with the prior art, the precise PVC high-calcium fill metering and feeding device has the advantages of easiness in blanking, accuracy in feeding, simple and attractive structure, high conveying capacity, no fluctuation, good self-cleaning performance, high metering precision, wide application scope, etc.

Owner:SHANGHAI JINHU EXTRUSION EQUIP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com