Rod type convergence gauge and using method thereof

A technology of extensometer and measuring rod, which is applied in the direction of adopting mechanical device, mechanical solid deformation measurement, measuring device, etc., which can solve the difficulty of popularization and application of digital display extensometer, difficulty in connecting the extensometer and high point, and the reduction of durability of the instrument and other problems, to achieve the effect of convenient observation, avoiding the problem of deflection drooping error, and improving the measurement precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] An embodiment of the present invention will be further described below in conjunction with accompanying drawing:

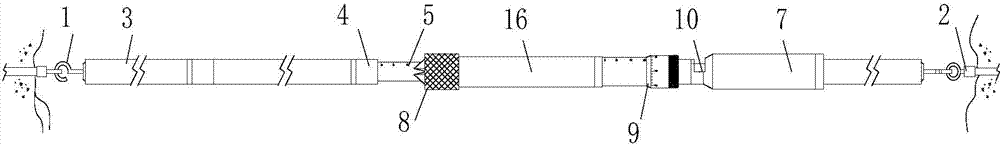

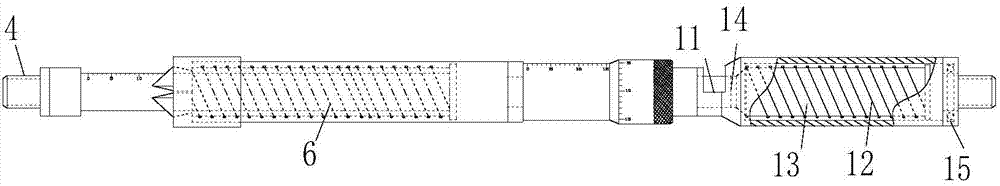

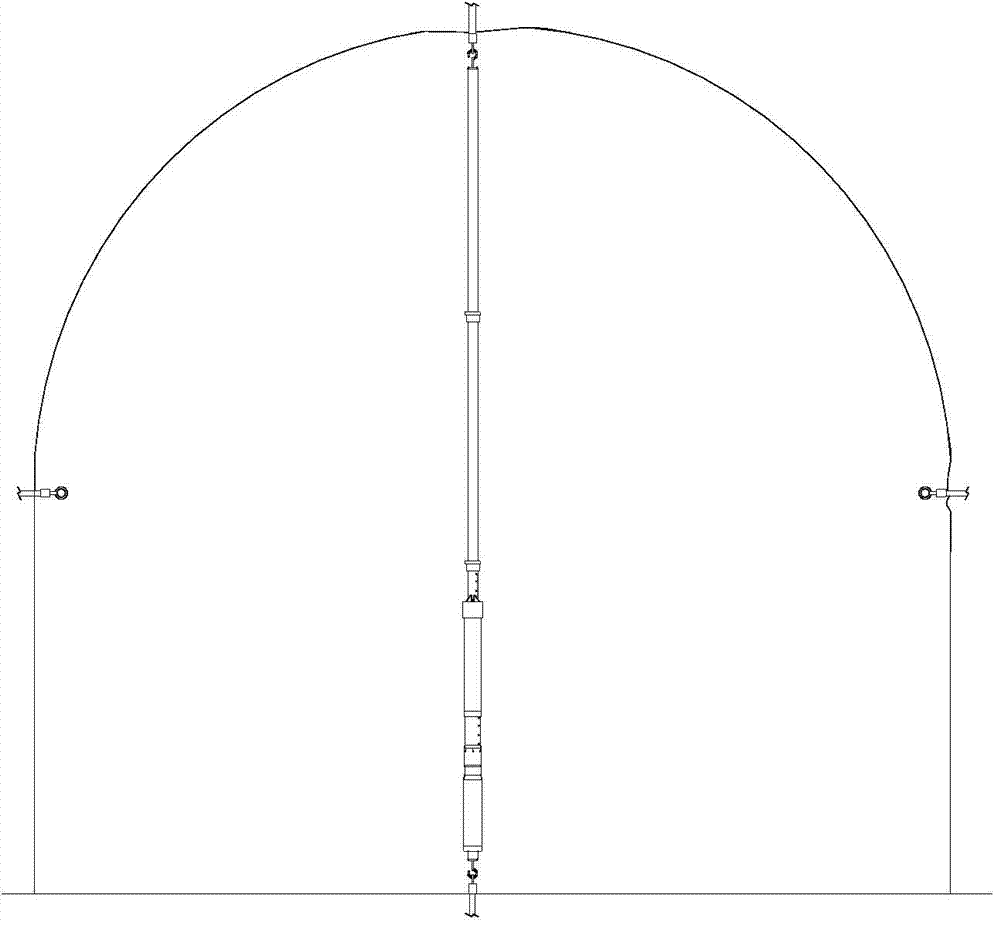

[0018] The metal rod type extensometer of the present invention is mainly composed of a universal hook 1, a fixed anchor head 2, a metal light measuring rod 3, a connecting bolt nut 4, and a main measuring reading rod. The main reading rod includes a built-in steel measuring ruler 5, a measuring ruler spring 6, a metal pressure rod 7, a measuring ruler locking ring 8, a spiral micrometer 9, a reference window 10, a force measuring spring 12, a force measuring spring Guide rod 13, bearing 15, hollow steel rod body 16; the fixed anchor head 2 is welded by a steel sleeve with internal threads and a steel shackle, and the diameters of the inner nuts are respectively: M24, M22, M20, M18; the metal light measuring rod 3 is made of a thin-walled stainless steel tube with small dead weight and high rigidity, and the lengths selected according to actual measurement ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com