Online analysis and detection device and method for heated cigarette smoke

A cigarette smoke and detection device technology, which is applied in the field of online analysis and detection devices for heated cigarette smoke, can solve problems such as blank research, avoid the use of toxic organic solvents, improve instrument measurement precision, and reduce pipeline pollution Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

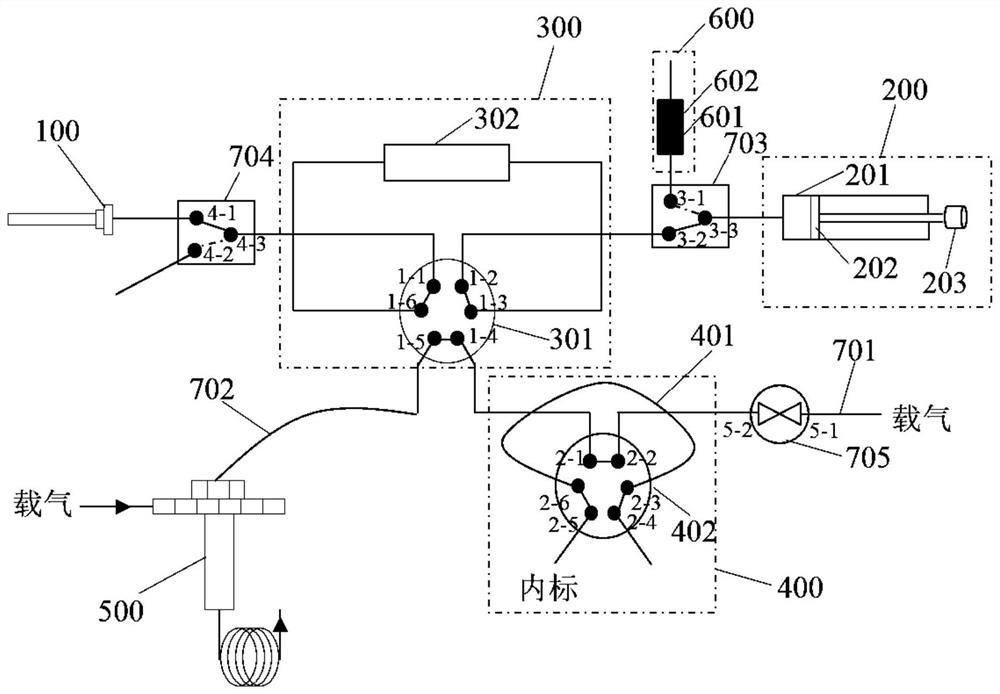

[0090] On-line detection of whole smoke components of heated cigarettes.

[0091] Gas chromatography mass spectrometer (GC / MS) is used as the analysis detector, and the online analysis device adopts figure 1 The online analysis and detection device shown. The volume of the sample quantitative loop is 0.5mL, the internal standard gas is ethanol standard gas, the volume of the internal standard sample quantitative loop is 0.25mL, and the insulation temperature of the transmission line is 150°C.

[0092] Heated cigarette sample preparation and smoking: Before the experiment, the heated cigarette sample was placed in a constant temperature and humidity condition of temperature (22±1)°C and relative humidity (60±2)% for 48 hours. The suction parameters were a suction volume of 55 mL, a suction duration of 2 s, a suction interval of 30 s, and a bell-shaped suction curve.

[0093] GC conditions: Agilent DB-WAXETR quartz capillary column (60m×250μm×0.25μm); inlet temperature 250°C; ...

Embodiment 2

[0098] Puff-by-puff analysis of heated cigarette smoke

[0099] Example 1 was repeated according to the same steps described above, and the sample quantification loop captured the flue gas port by port according to the suction port sequence for online analysis.

Embodiment 3

[0101] On-line detection of gas phase components in heated cigarette smoke.

[0102] Example 1 was repeated according to the same steps described above, a Cambridge filter was added to the cigarette holder, and the vapor phase of the heated cigarette smoke was analyzed on-line.

PUM

| Property | Measurement | Unit |

|---|---|---|

| ionization potential | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com