Method for measuring aluminium content in sherardizing agent

A technology of aluminum content and zinc sherardization, applied in the field of chemical analysis, can solve problems such as unsatisfactory, complicated detection, and inability to obtain test results of aluminum content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

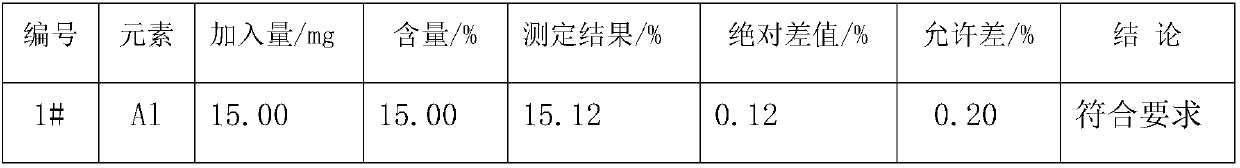

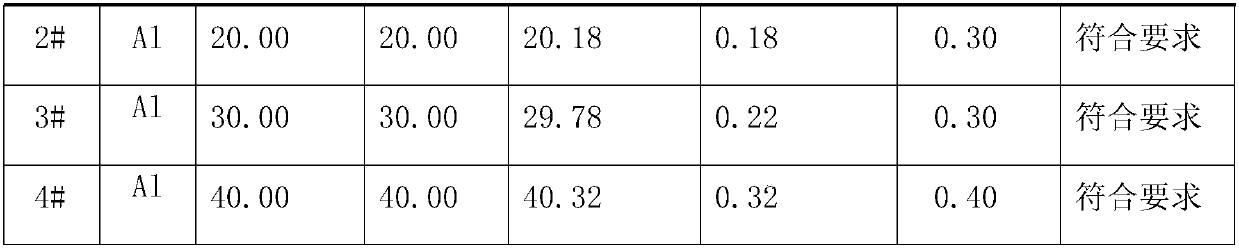

Examples

Embodiment

[0078] Step 1: Weighing the sample

[0079] Weigh 0.1000g of the zinc-seeding agent sample with a ten-thousandth electronic balance, and place it in a 50mL platinum crucible;

[0080] Step 2: Pretreatment Melting

[0081] Add about 2g of potassium pyrosulfate to the platinum crucible containing the zinc-seeding agent sample, and mix it with a thin iron wire; in a high-temperature resistance furnace, heat to 700°C to 750°C to melt the sample until the sample is completely melted; take it out , placed on a heat-resistant asbestos board, and cooled to room temperature;

[0082] Step 3: Melt leaching

[0083] Melt leaching includes water preparation, preparation of hydrochloric acid solution, preparation of co-solvent solution and sample dissolution; preparation of ultrapure water: use ultrapure water machine to prepare ultrapure water, and its conductivity requirement is not more than 0.10mS / m; preparation of hydrochloric acid solution: in a 400mL beaker, add 200mL ultrapure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com