Method for extracting and measuring ABA (abscisic acid) of strawberry

A strawberry and extract technology, applied in the direction of measuring devices, instruments, scientific instruments, etc., to achieve the effects of less reagent consumption, accurate and reliable results, and improved extraction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

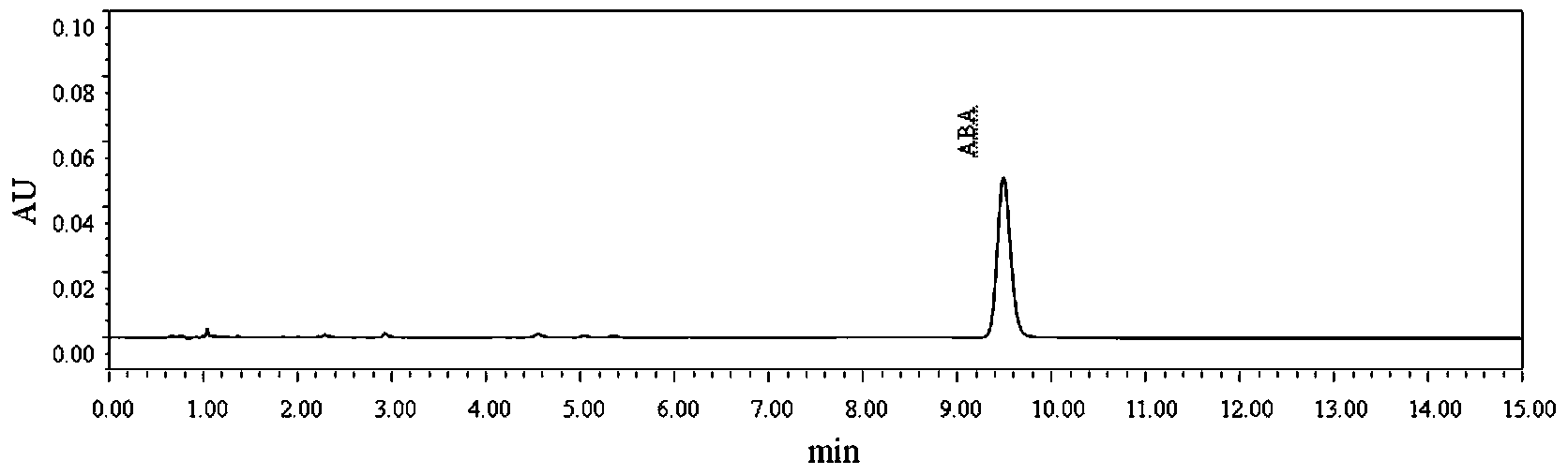

[0027] 1. Preparation of standard solution: take 25mg of ABA reference substance, add 10mL of chromatographically pure methanol to dissolve and constant volume, to make a standard solution mother solution with a concentration of 2.5mg / mL (it should be noted that when the mother solution is not When used immediately, it needs to be stored at -20°C), and then the mother solution was diluted into 7 concentration gradients of 0.1, 0.25, 0.5, 0.75, 1, 2.5, and 5 μg / mL;

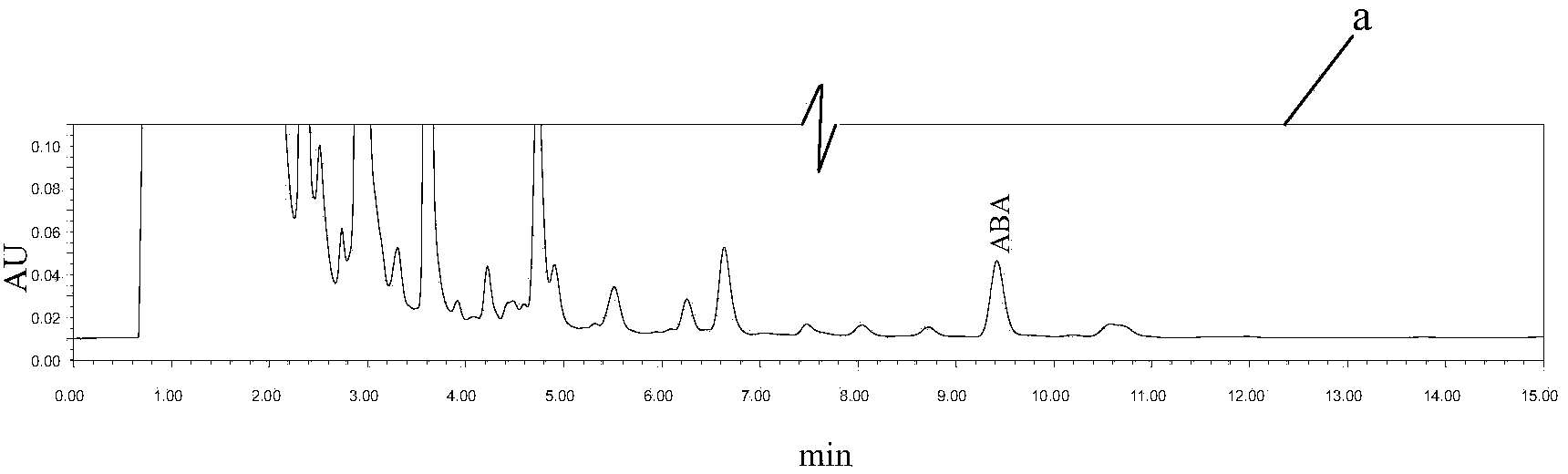

[0028] 2. Preparation of extract: Weigh 5g of strawberry green fruit pulp, grind it into powder with liquid nitrogen, then place it in a stoppered Erlenmeyer flask, and add 200mL of extraction solvent (methanol, ethyl acetate, formic acid at 50:50 : 1 volume ratio), after vigorously shaking and extracting for 5 minutes, the residue was discarded by suction filtration, and the obtained filtrate was rotary evaporated to dryness under reduced pressure at 35°C, and then the mobile phase of ultra-high performance liquid ...

Embodiment 2

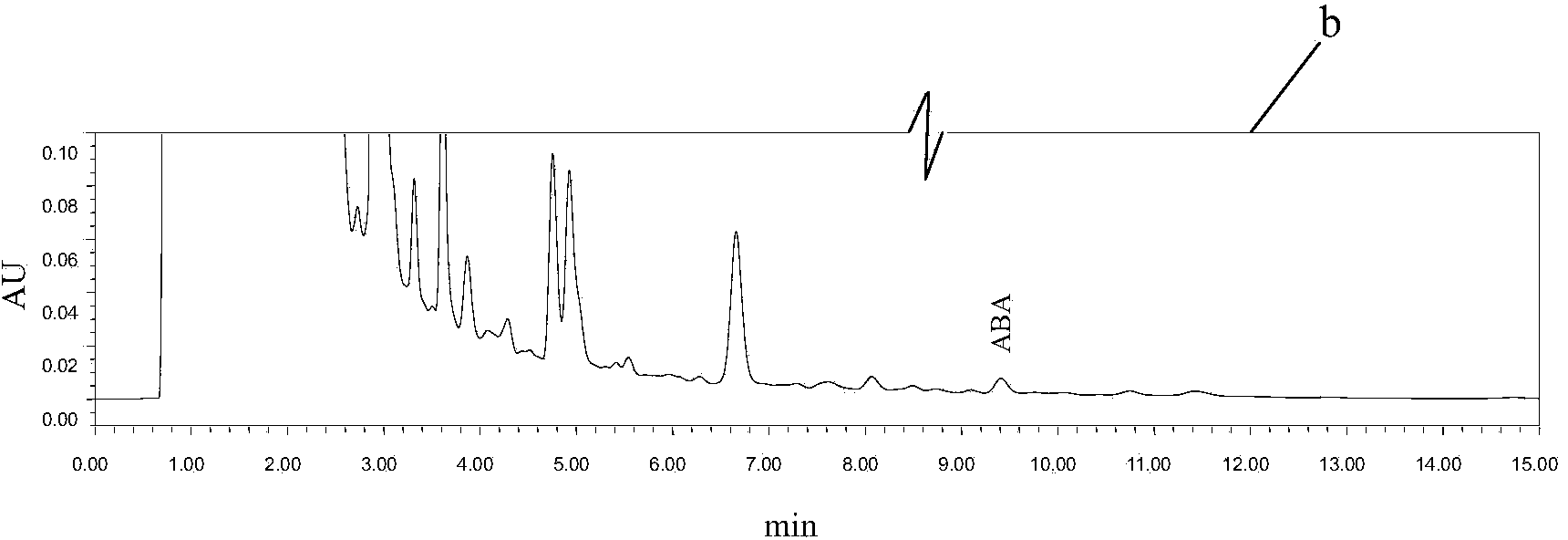

[0041] Preparation of extract: Weigh 10g of strawberry red fruit pulp, grind it into powder with liquid nitrogen, then put it into a stoppered Erlenmeyer flask, and add 400mL of extraction solvent (methanol, ethyl acetate, formic acid at 50:50:1 mixed by volume ratio), shake vigorously to extract for 5 minutes, remove the residue by suction filtration, place the obtained filtrate at 35°C and rotary evaporate to dryness, then add the mobile phase of ultra-high performance liquid chromatography to dissolve, and collect the solution to obtain Strawberry ABA extract, the resulting extract is passed through a 0.22 μm filter membrane to obtain the test solution;

[0042] Determination: Take the liquid to be tested prepared in this embodiment and inject it into an ultra-high performance liquid chromatograph with the same chromatographic conditions as in Example 1 for analysis and determination, and obtain the ultra-high performance liquid chromatogram of the liquid to be tested, speci...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com