Device and method for measuring cloud point pressure and density of supercritical CO2 microemulsion system

A cloud point pressure and microemulsion technology, applied in the measurement of fluid pressure, measurement device, specific gravity measurement, etc., can solve the problems of many operation steps, high cost, inability to meet the test, etc., achieve precise control of volume change, and reduce manufacturing costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

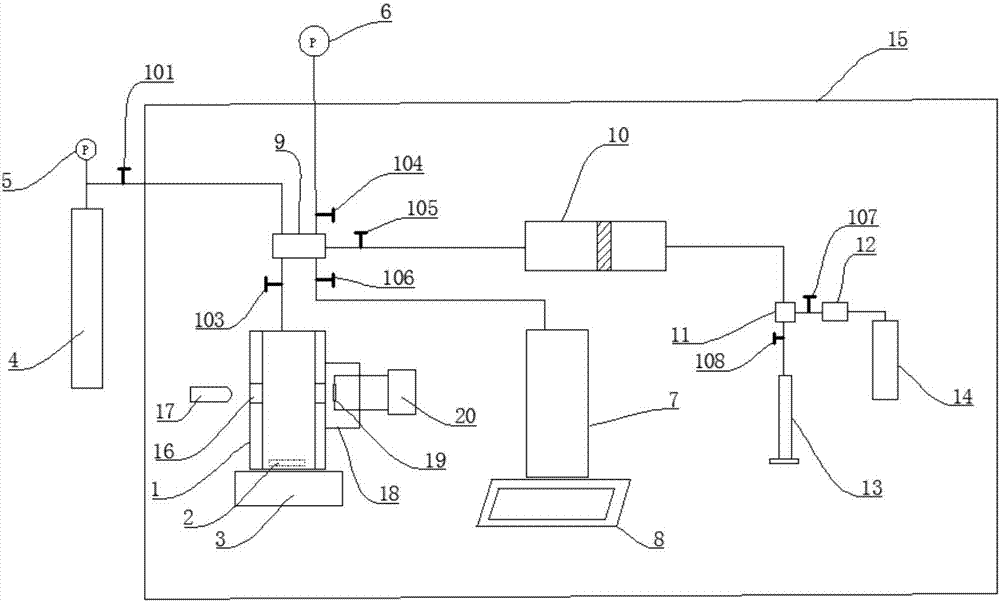

Method used

Image

Examples

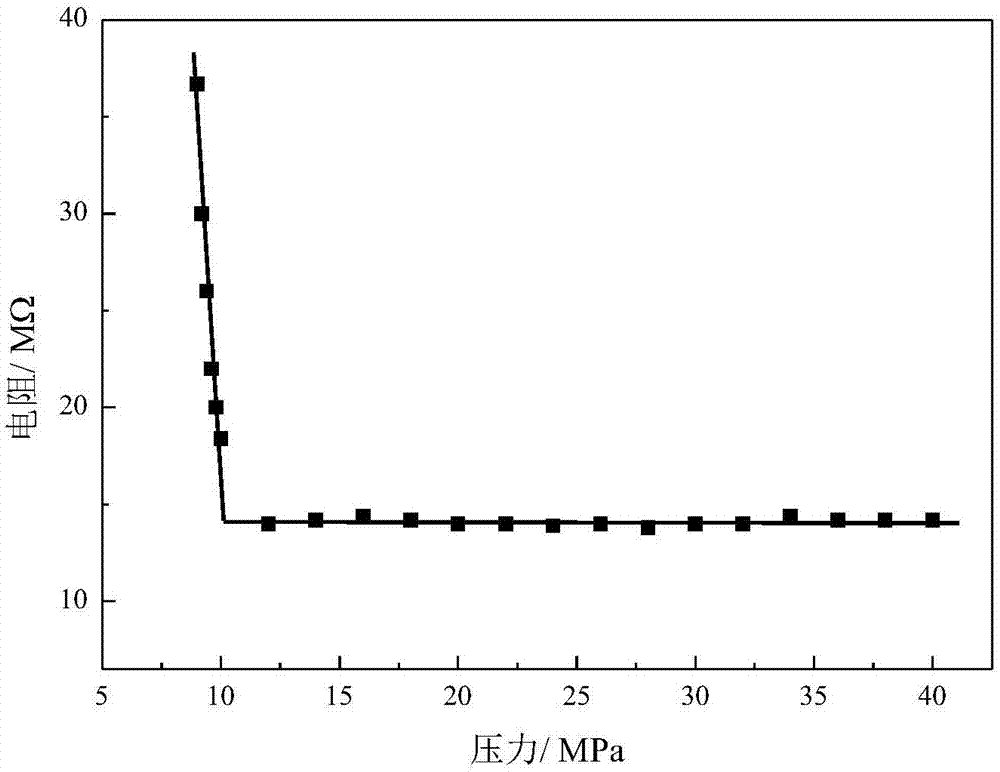

Embodiment 1

[0076] Control the temperature at 50°C, weigh 0.01g of surfactant sodium bis(2-ethylhexyl) succinate sulfonate (AOT), dissolve it in a mixed solvent composed of 1g of water and 10g of ethanol, and add it to a visual container , adjust the electromagnetic stirring speed to 100rad / min, and the CO in the gas storage tank 2 Into the visible container, until the pressure in the visible container is 19MPa, the added CO 2 mass, i.e. m 2 -m 3 The value is 85.0g, the volume of the visible container is increased through the intermediate container, and the curve of the system pressure and the resistance value of the photoresistor is recorded as figure 2 As shown, it can be concluded that the cloud point pressure of the system is 10.2MPa, restore the initial state of the visible container, increase the volume of the visible container through the intermediate container again until the pressure reaches 10.2MPa, and a total of 27.2 mL of water is discharged from the intermediate container...

Embodiment 2

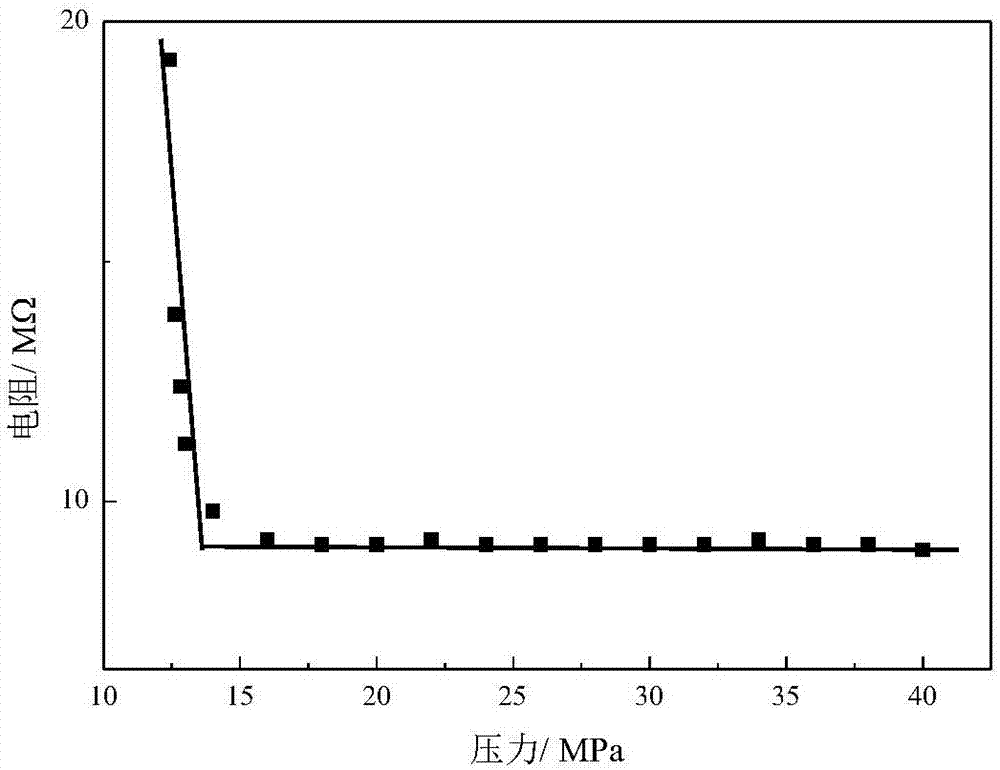

[0078] Control the temperature at 50°C, weigh 0.02g of surfactant sodium bis(2-ethylhexyl) succinate sulfonate (AOT), dissolve it in a mixed solvent composed of 1g of water and 10g of ethanol, and add it to a visual container In the process, the electromagnetic stirring speed is adjusted to 200rad / min, and the CO in the gas storage tank is 2 Into the visible container, until the pressure in the visible container is 19MPa, the added CO 2 mass, i.e. m 2 -m 3 The value is 86.2g, the volume of the visible container is increased through the intermediate container, and the curve of the system pressure and the resistance value of the photoresistor is recorded as image 3 As shown, it can be concluded that the cloud point pressure of the system is 13.6MPa, restore the initial state of the visible container, increase the volume of the visible container through the intermediate container again until the pressure reaches 13.6MPa, and a total of 9.0 mL of water is discharged from the in...

Embodiment 3

[0080] Control the temperature at 60°C, weigh 0.03g of surfactant sodium bis(2-ethylhexyl)succinate sulfonate (AOT), dissolve it in a mixed solvent composed of 1g of water and 10g of ethanol, and add it to a visual container In the process, the electromagnetic stirring speed is adjusted to 500rad / min, and the CO in the gas storage tank is 2 Into the visible container, until the pressure in the visible container is 19MPa, the added CO 2 mass, i.e. m 2 -m 3The value is 85.2g, the volume of the visible container is increased through the intermediate container, and the curve of the system pressure and the resistance value of the photoresistor is recorded as Figure 4 As shown, it can be concluded that the cloud point pressure of the system is 16.0MPa, restore the initial state of the visible container, increase the volume of the visible container through the intermediate container again until the pressure reaches 16.0MPa, the intermediate container has a total of 0.72 mL of wate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| volume | aaaaa | aaaaa |

| electrical resistance | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com