Conical twin-screw extruder PVC high calcium filling precision metering feeding equipment

A conical twin-screw and polyvinyl chloride technology, which is applied in the field of metering and feeding equipment, can solve the problems affecting the extrusion performance and output of the conical twin-screw extruder, affecting the quality of products, and inaccurate metering and feeding. To achieve the effect of simple and beautiful structure, easy cutting and good self-cleaning performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

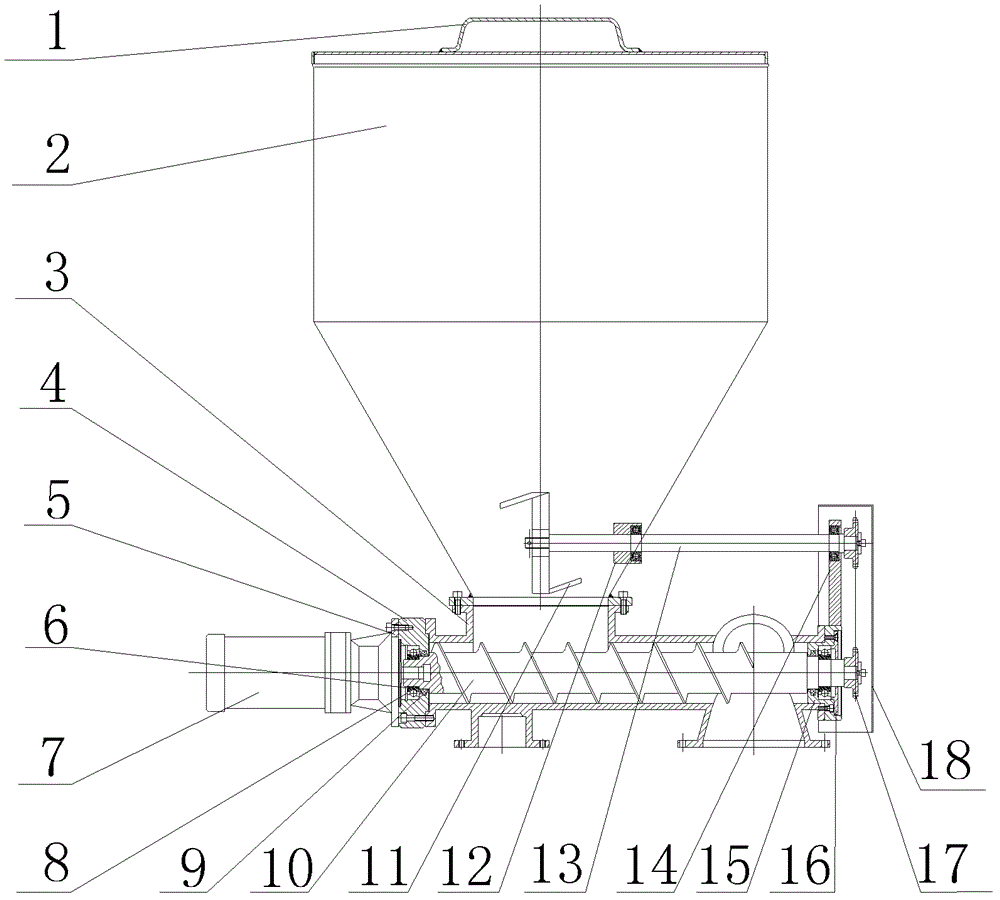

[0025] A conical twin-screw extruder polyvinyl chloride high calcium filled precision metering feeding equipment, the structure is as follows figure 1 shown, including:

[0026] Material storage device: composed of feeding hopper 2 and hopper cover 1 arranged on the upper part of feeding hopper 2;

[0027] Mixing device: including feeding barrel 3 and feeding screw 10, feeding barrel 3 is set at the lower part of feeding hopper 2, and feeding screw 10 is set in feeding barrel 3;

[0028] Drive transmission device: including drive motor 7, motor connecting plate 5, motor connecting body 4, first bearing seat 15, deep groove ball bearing 6, bearing retaining ring 8, felt ring 9 and bearing cover 16, one part of motor connecting plate 5 One side is connected with the drive motor 7, the other side of the motor connection plate 5 is connected with one side of the motor connection body 4 and the feeding screw 10, the other side of the motor connection body 4 is connected with the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com