Construction method of aerial micro-pipes

A construction method and micro-pipe technology, applied in the direction of optical fiber/cable installation, etc., can solve the problems of being easily damaged by wind, hail, ice and snow, large spans of overhead optical cables, and difficult repairs, etc., achieving a wide range of applications and easy repairs , restore the effect of fast communication

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

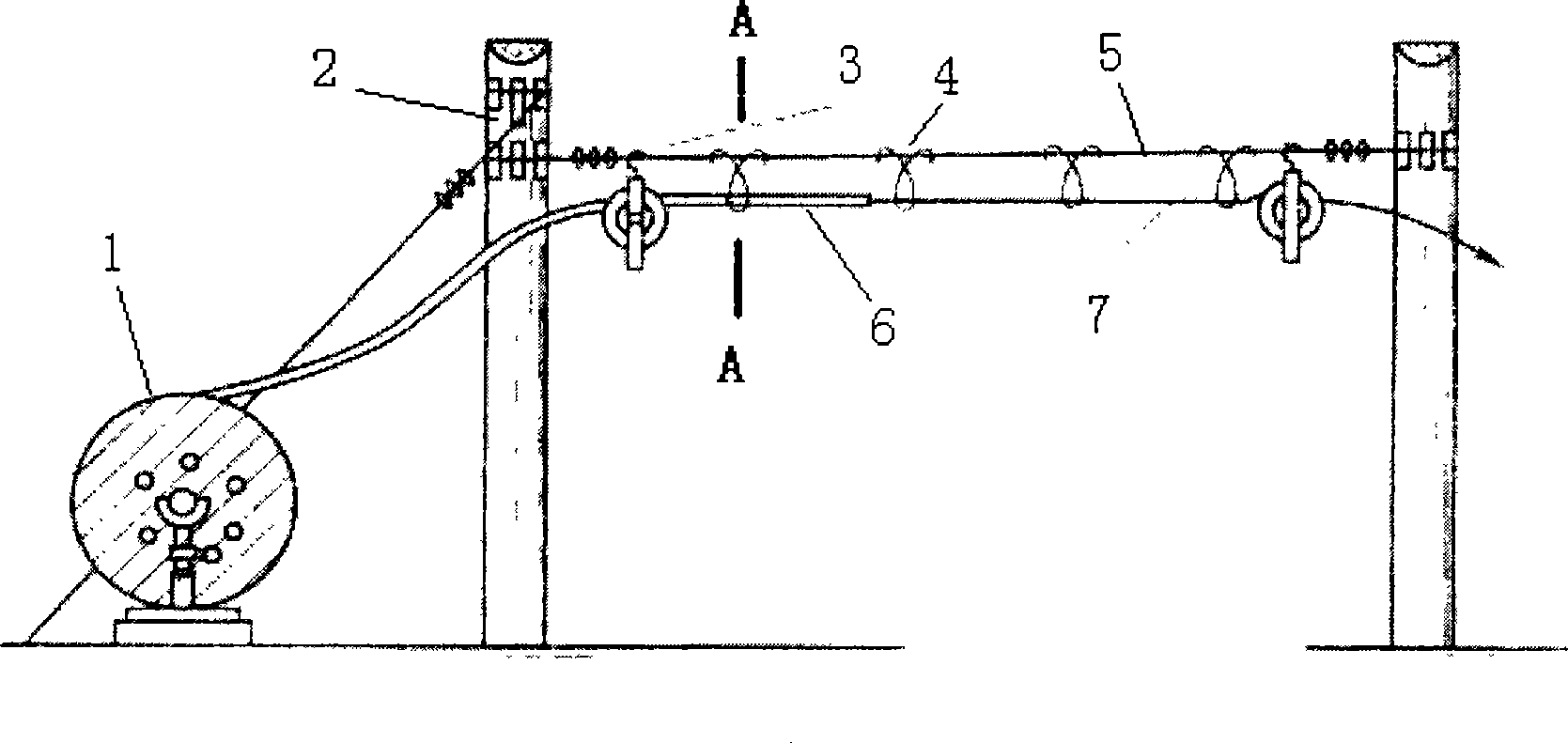

[0018] The construction method of overhead micro-pipe that the present invention proposes, its construction schematic diagram is as figure 1 shown, including the following steps:

[0019] (1) hang steel strand 5 between two utility poles 2, pulley 3 is set on steel strand, a plurality of hooks 4 are set between adjacent two pulleys;

[0020] (2) Pull out the optical cable sub-tube 6 from the optical cable sub-tube reel 1 with the traction rope 7, so that the optical cable sub-tube 6 passes through the pulley 3 and then penetrates into the hook 4 on the steel strand;

[0021] (3) pull the traction rope 7, so that the optical cable sub-tube 6 is erected between the utility poles 2;

[0022] (4) The microcable is blown into the microtube 8 of the subtube 6 of the aerial optical cable by means of air blowing.

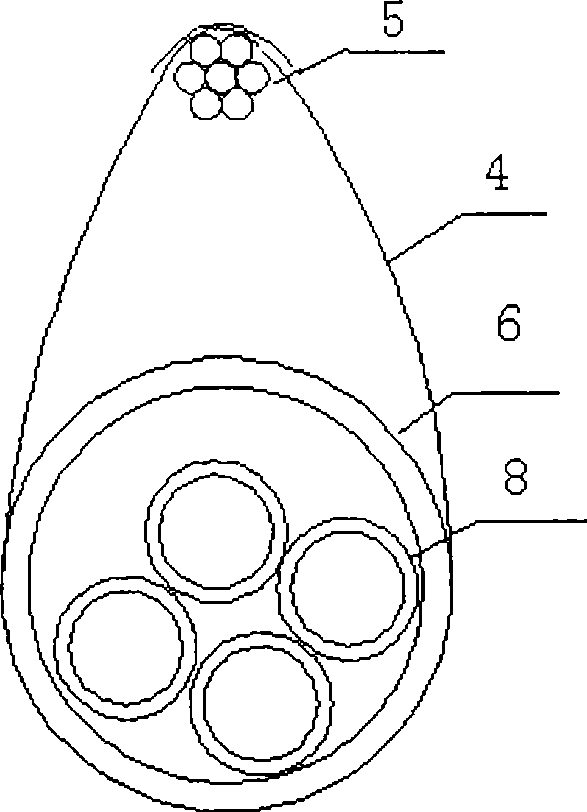

[0023] In the above method, the optical cable sub-tube can be a bundle tube, and the bundle tube is provided with 3-4 microtubes, such as figure 2 shown.

[0024] In o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com