Removable shround and pump deck for boiling water nuclear reactor

A technology for pump covers and nuclear reactors, applied in the direction of reactors, reactor fuel elements, climate sustainability, etc., can solve problems such as metal overstress corrosion cracking, and achieve the effect of easy repair and/or replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

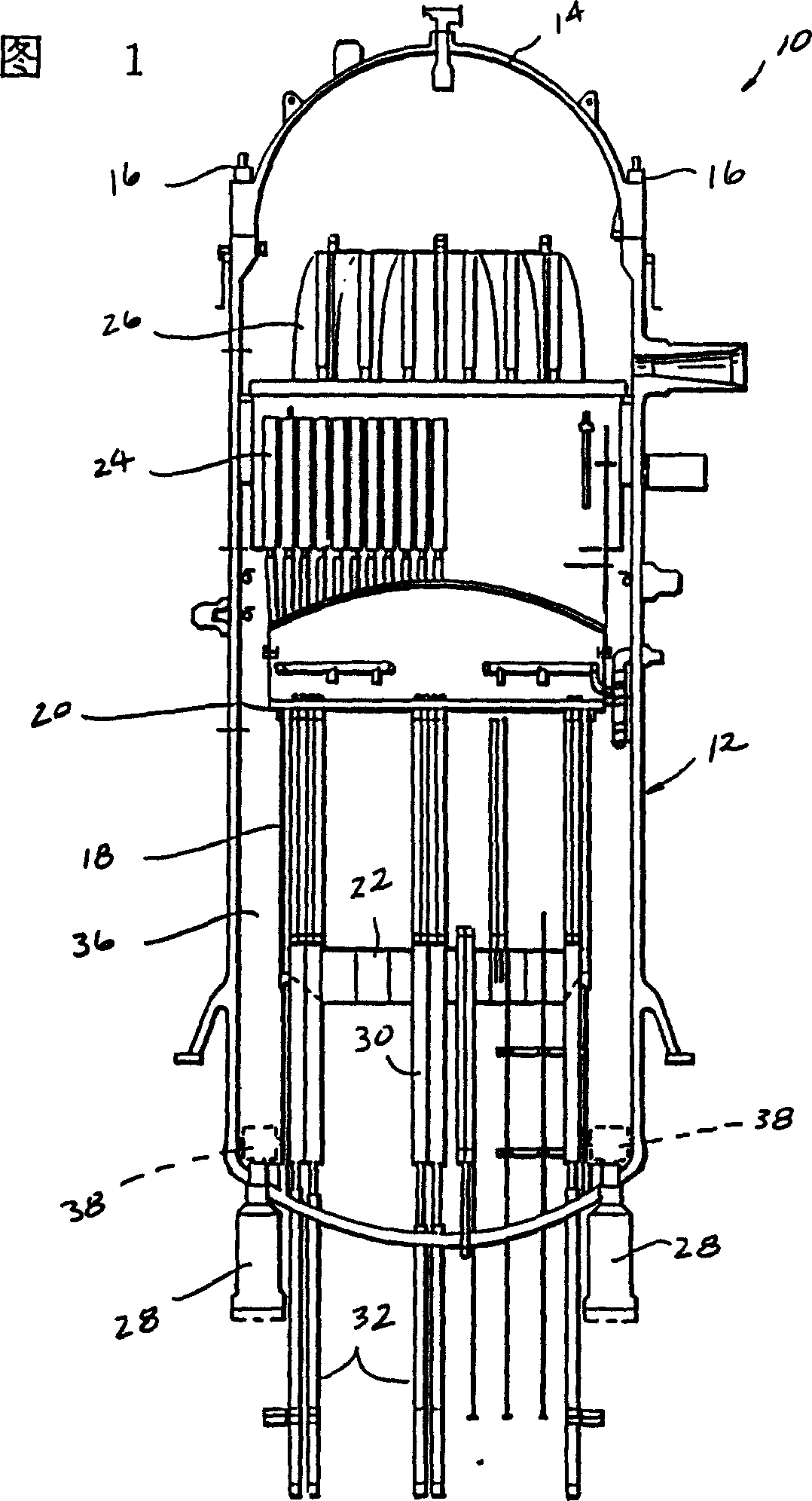

[0024] Referring to FIG. 1 , an advanced boiling water reactor 10 with an internally welded core cylinder is illustrated. However, before discussing the cylindrical structure, it may be instructive to briefly describe the general structure of the reactor.

[0025] The reactor pressure vessel (or RPV) 12 is essentially a cylindrical vessel with a single full diameter removable top cover 14 . The top cover 14 is bolted to the cladding as indicated at 16 . The RPV 12 houses the core barrel 18 , top guide apparatus 20 , core plate apparatus 22 , steam separator 24 and steam dryer 26 . Also included in the reactor plant are an in-reactor pump 28 (here also referred to as a jet pump), control rods 30 and associated drives 32 . The control rods 30 occupy the space between the fuel assemblies within the reactor core in a conventional manner and can be withdrawn from the core into guide tubes below the core when the plant is in operation.

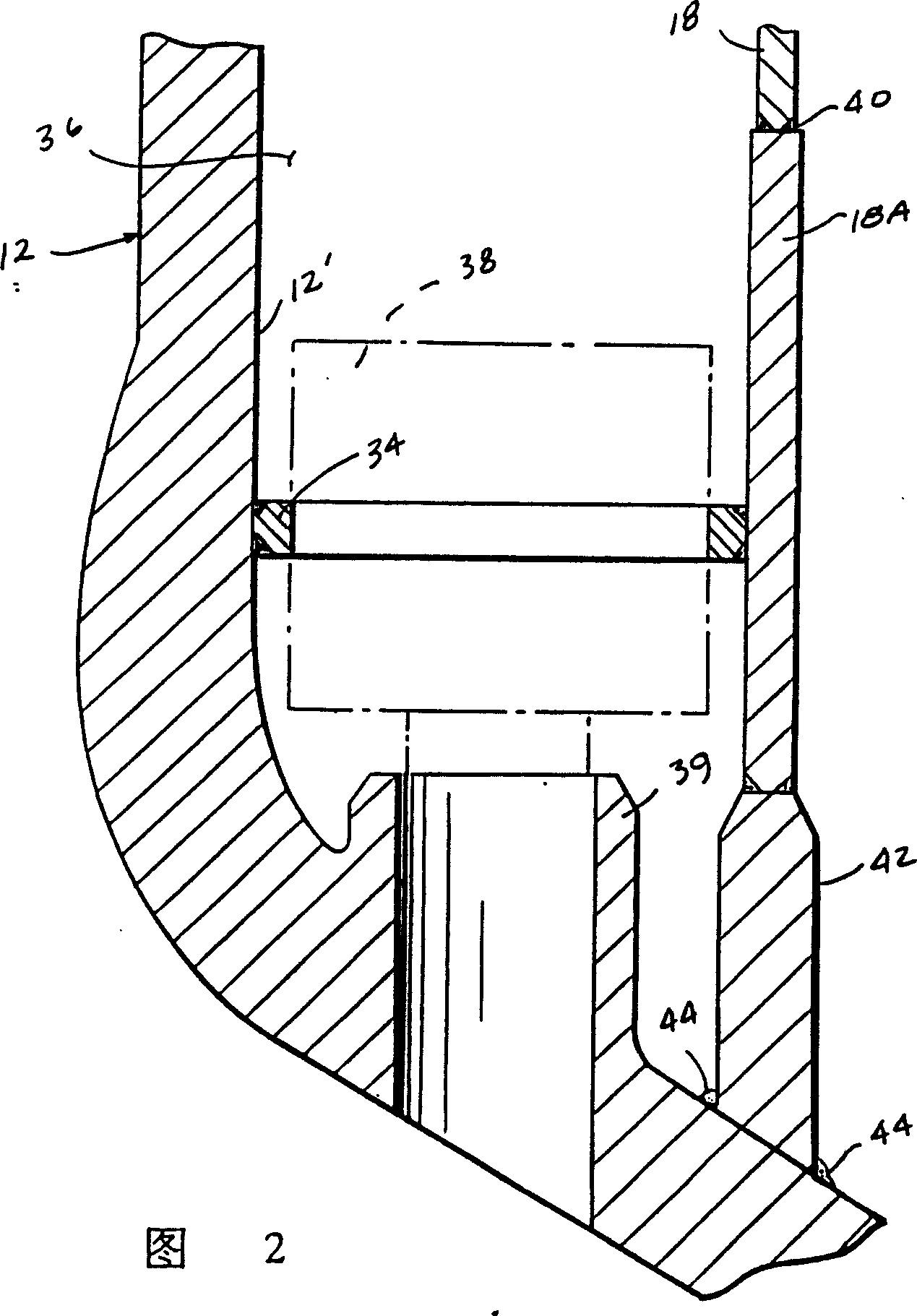

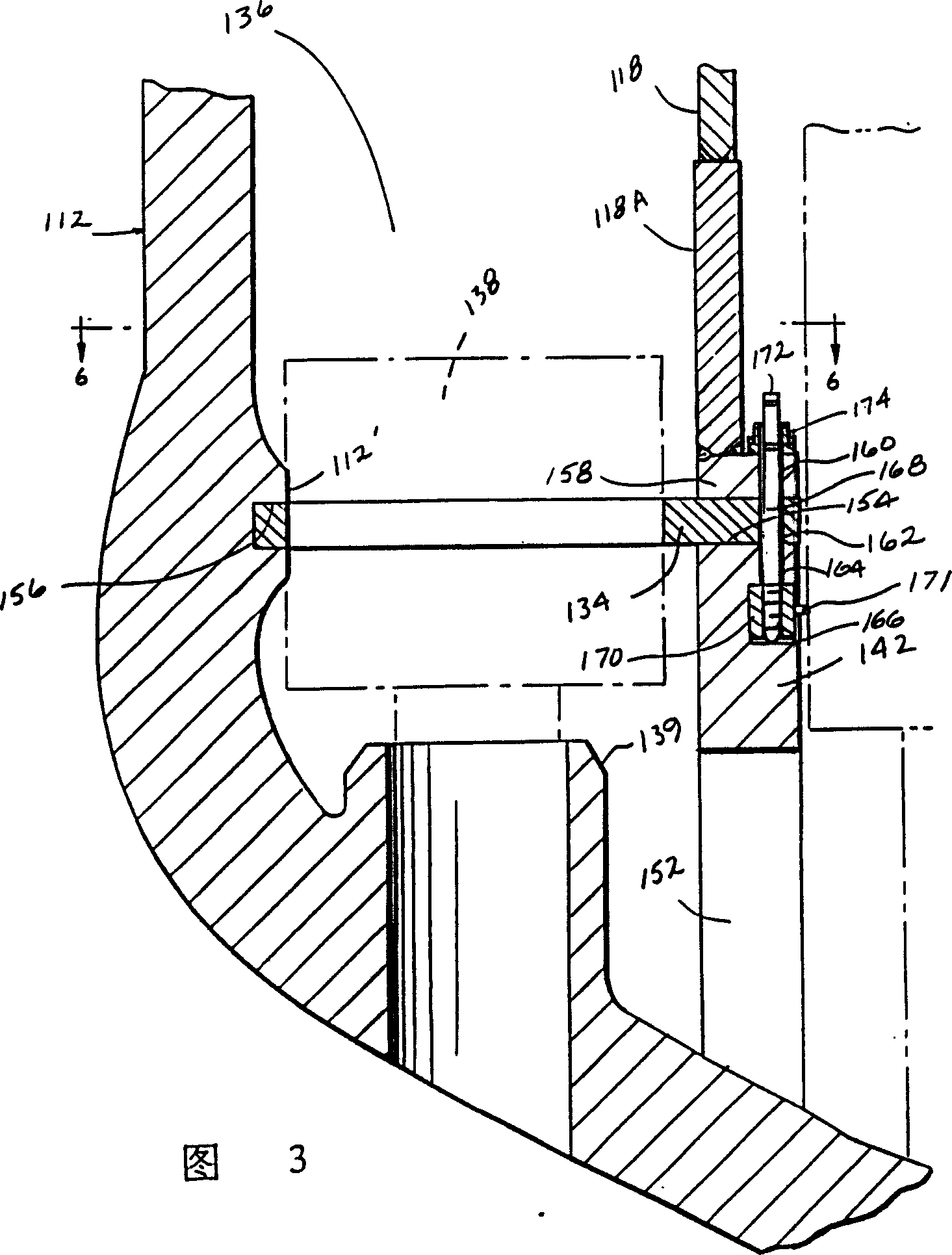

[0026] An annular pump cover plate 34, in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com