Construction method for paving road slot minitype communication pipe by urban area road

A construction method and road technology, applied in the direction of optical fiber/cable installation, etc., can solve the problems of insufficient detection capability of micro-control pipe jacking equipment, reduced advantages of network expansion, and danger of micro-control pipe jacking operations, etc., to achieve easy repair and construction risk The effect of small size and flexible construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

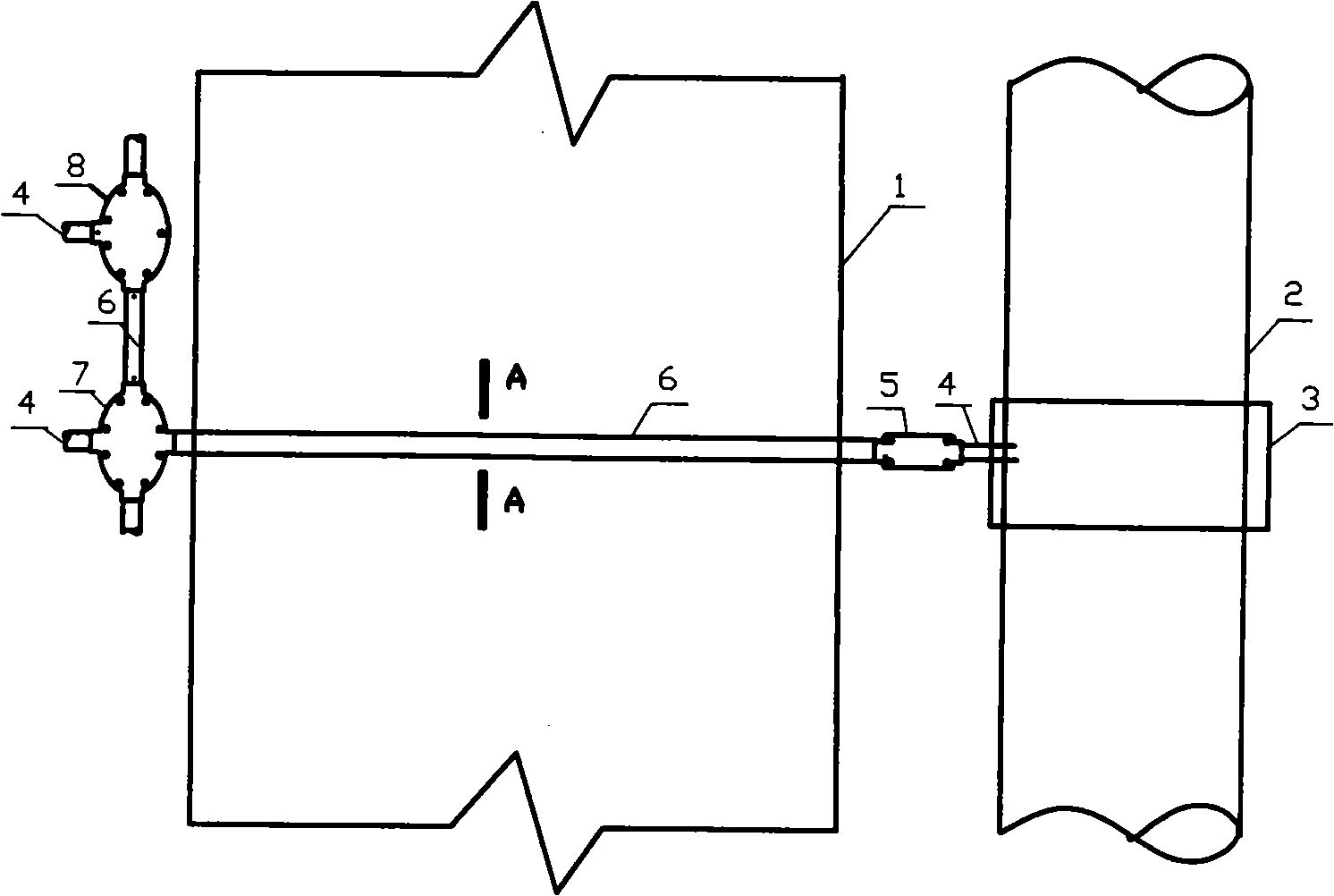

[0027] The present invention proposes the construction method of laying the micro-communication pipeline of the road groove by using urban roads, and its construction schematic diagram is as follows figure 1 shown, including the following steps:

[0028] (1) According to the set plan or design route, draw a groove line on the road 1, cut the road surface along the drawn groove line, dig out the groove 9, and make the bottom of the groove smooth;

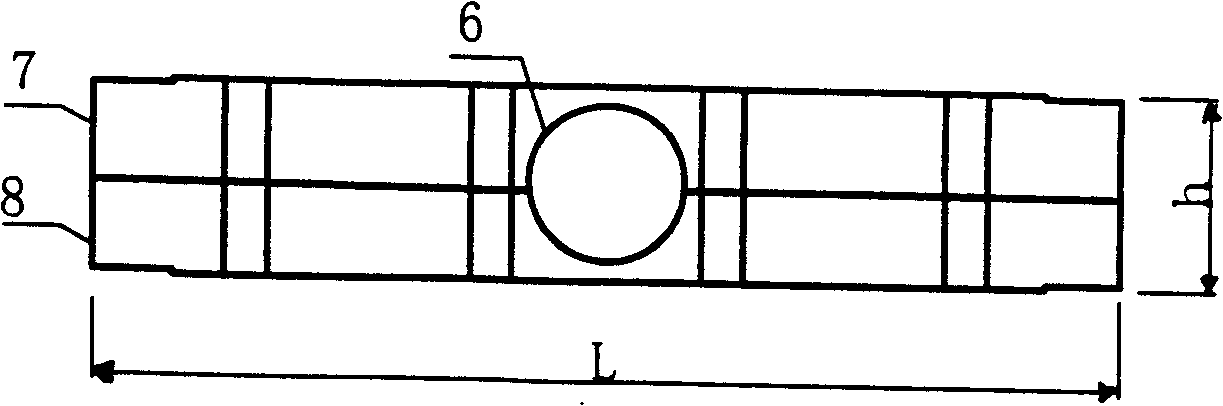

[0029] (2) Embed a four-way micropipe branching box 7 or a three-way micropipe branching box 8 at one end of the groove 9, and embed a micropipe joint box 5 near the manhole 3 or the transfer box at the other end of the groove;

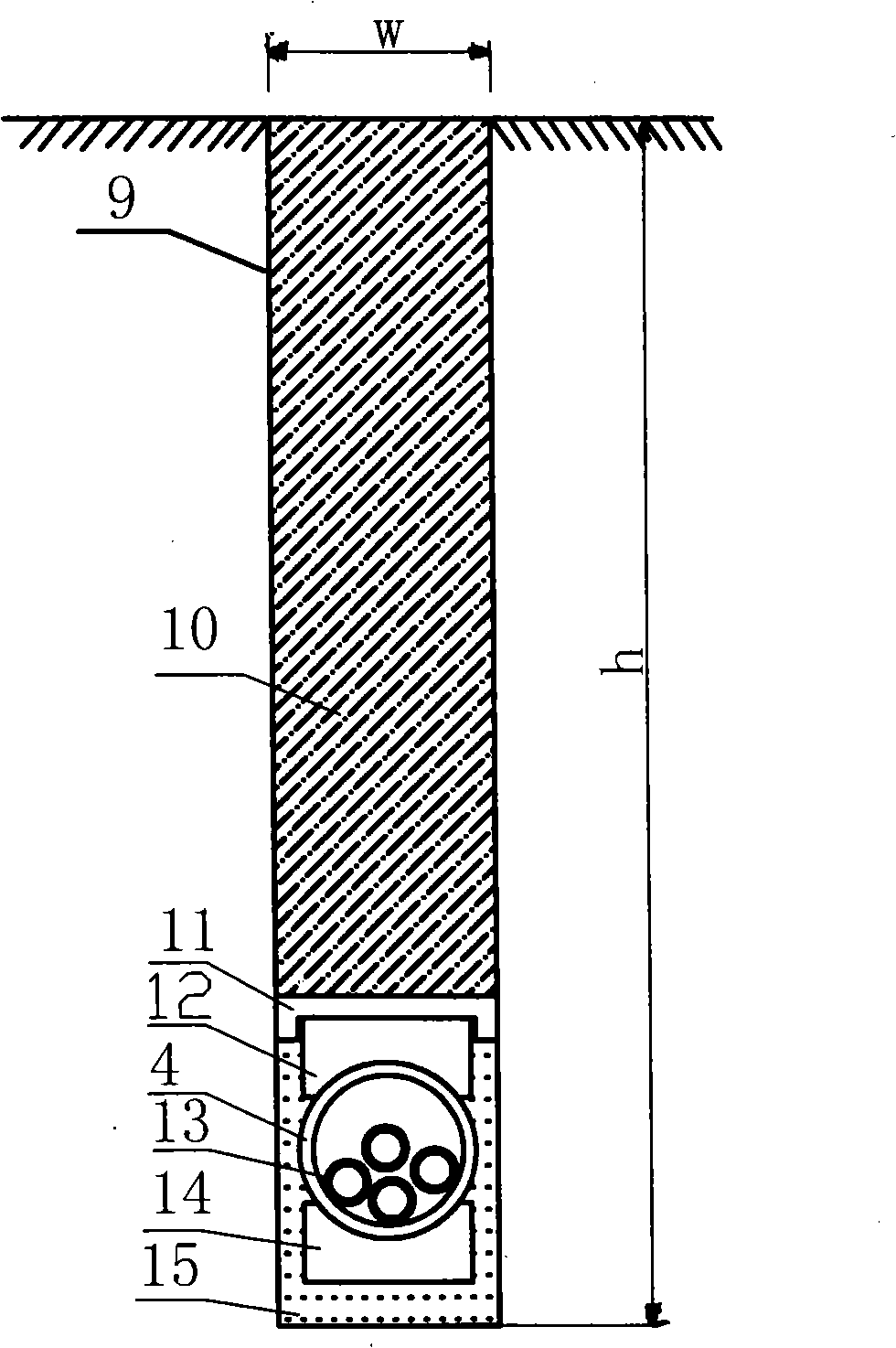

[0030] (3) spread fine sand 15 at the bottom of described groove 9, as figure 2 As shown, the thickness is 5 to 15 mm, and the pipe support 14 is laid flat on the fine sand, and the optical cable sub-tube 4 is placed on the pipe support 14 in the groove 9, and the two ends of the micro-cable sub-tube 4 are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com