Centrifugal pump impeller

A centrifugal pump, distance technology, applied in the field of centrifugal pumps, can solve problems such as unwanted vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

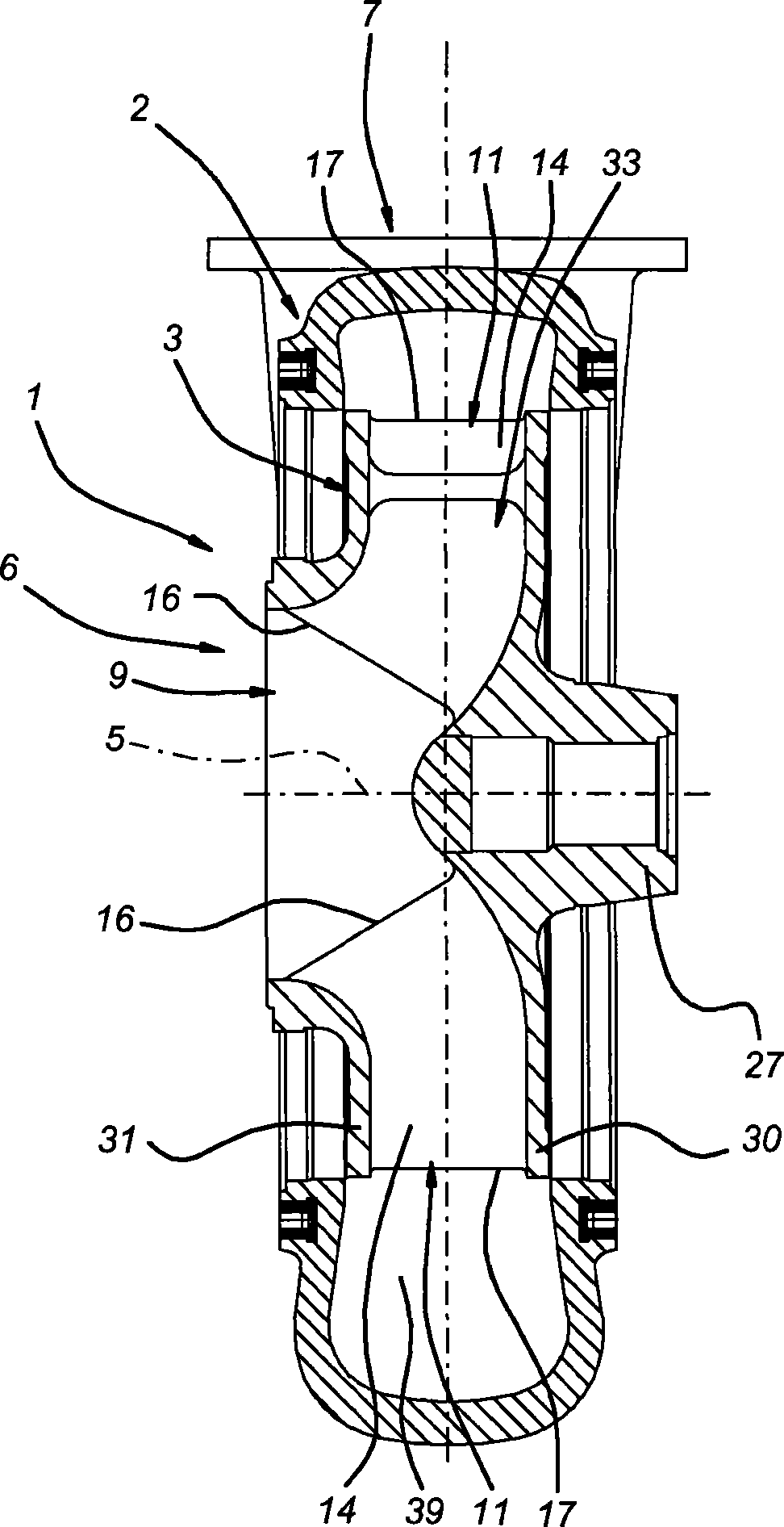

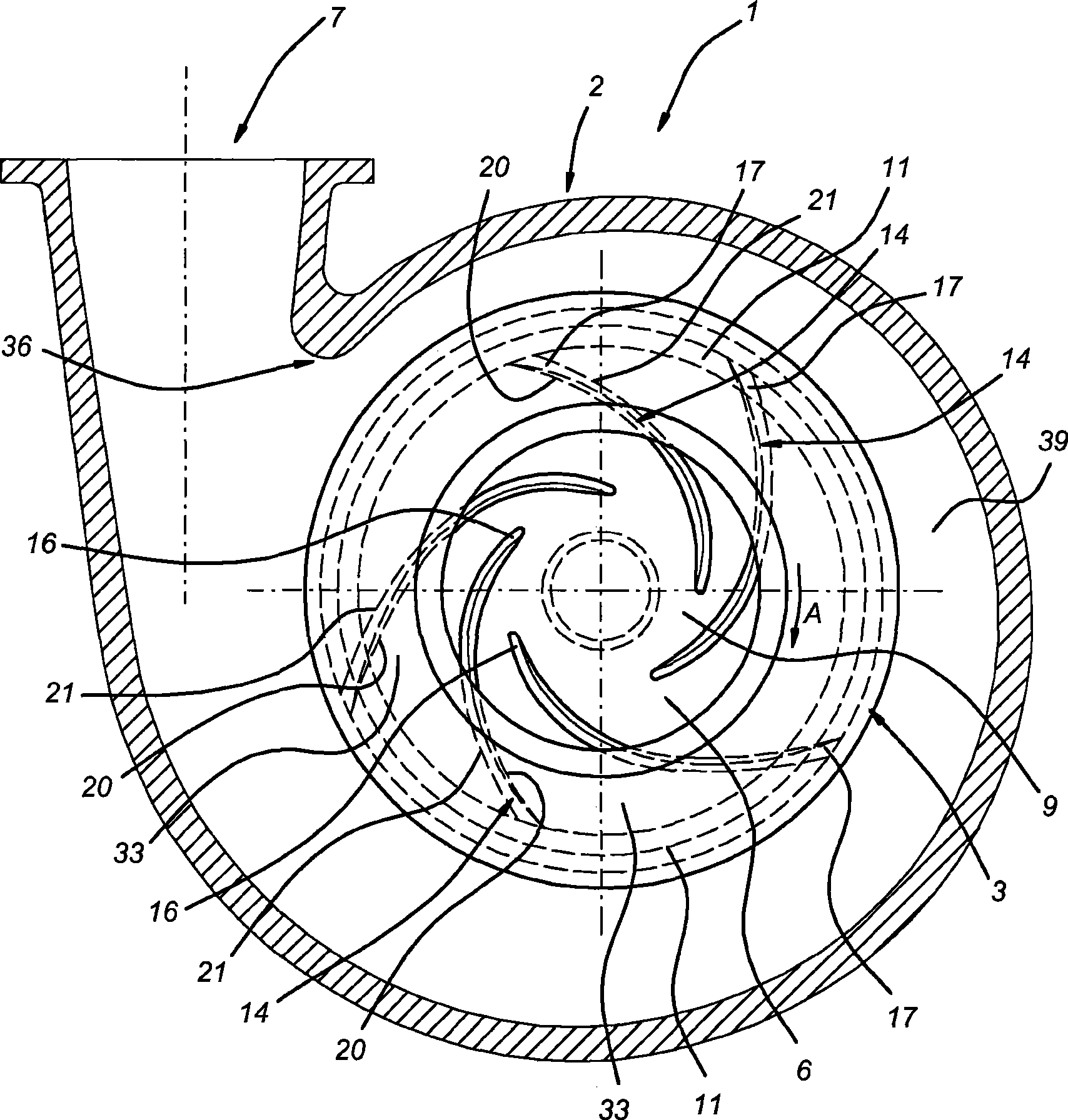

[0026] The centrifugal pump according to the invention is designated as a whole by the reference numeral 1 . The centrifugal pump 1 comprises a housing 2 which is helically shaped (see figure 2 ). The pump housing 2 comprises an axial inlet 6 and a tangential outlet 7 . The tangential outlet 7 is positioned transversely with respect to the housing 2 . In this exemplary embodiment, the tangential outlet 7 is designed as a nozzle. Furthermore, a rotor 3 is provided, which is arranged rotatably about an axial axis of rotation 5 within the housing 2 . The axial inlet 6 in the housing 2 is arranged centrally with respect to the rotor 3 .

[0027] The rotor 3 is usually formed from a single moulding. The rotor 3 comprises a hub 27 within which a shaft (not shown) mounted outside the housing 2 can be accommodated. The hub 27 defines the axis of rotation 5 of the rotor 3 . The rotor 3 further has a first wall or shaft housing 30 . The first wall 30 is connected to the hub 27 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com