Method for positioning and clamping straight-line guiding rail

A clamping method and technology of linear guide rails, applied in the field of positioning, positioning and clamping of linear guide rails, and clamping fields, can solve problems such as parallelism errors, incomplete tightness, difficulties, etc., to improve rigidity and stability, technology Improve the effect of expanding and eliminating accumulated errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

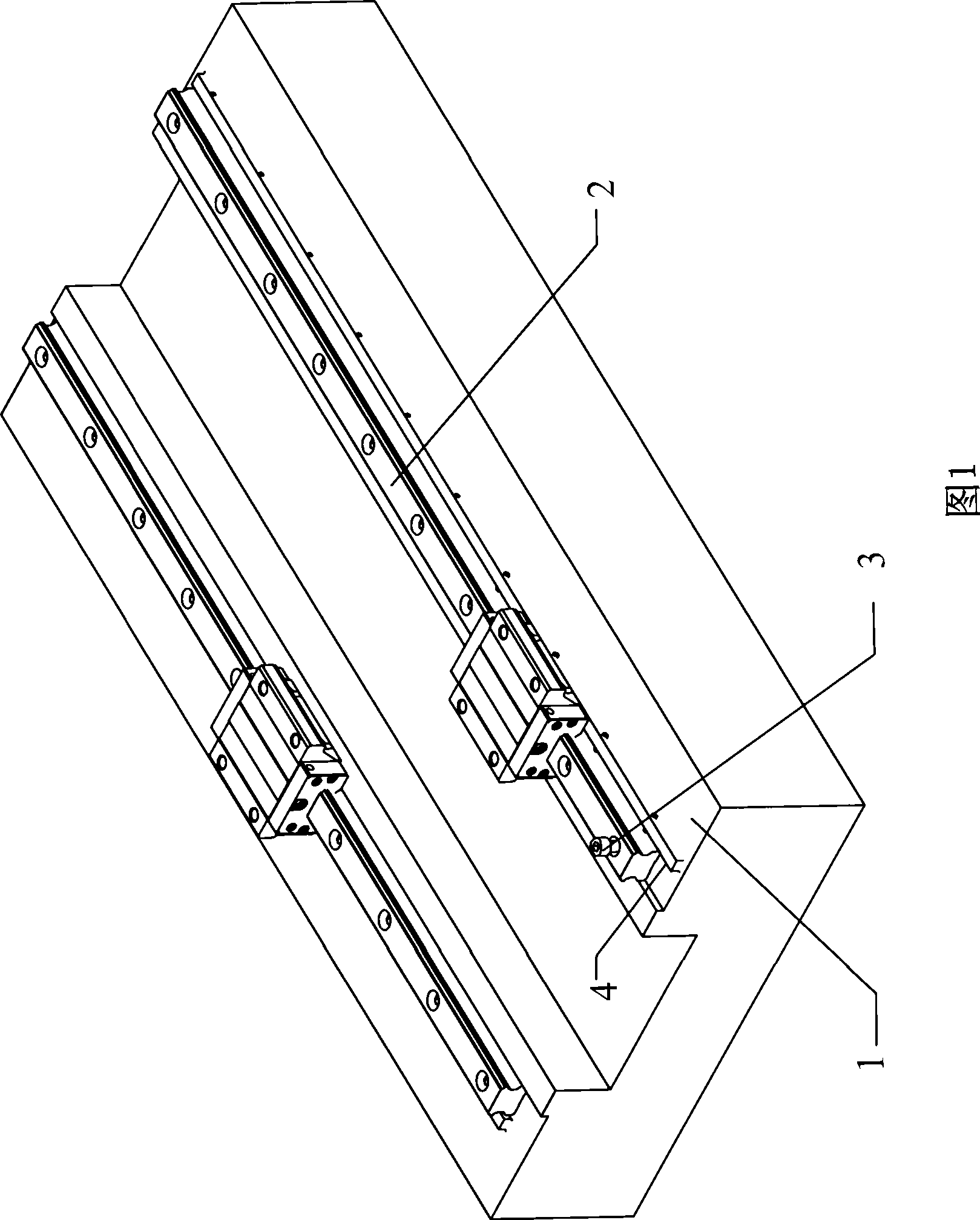

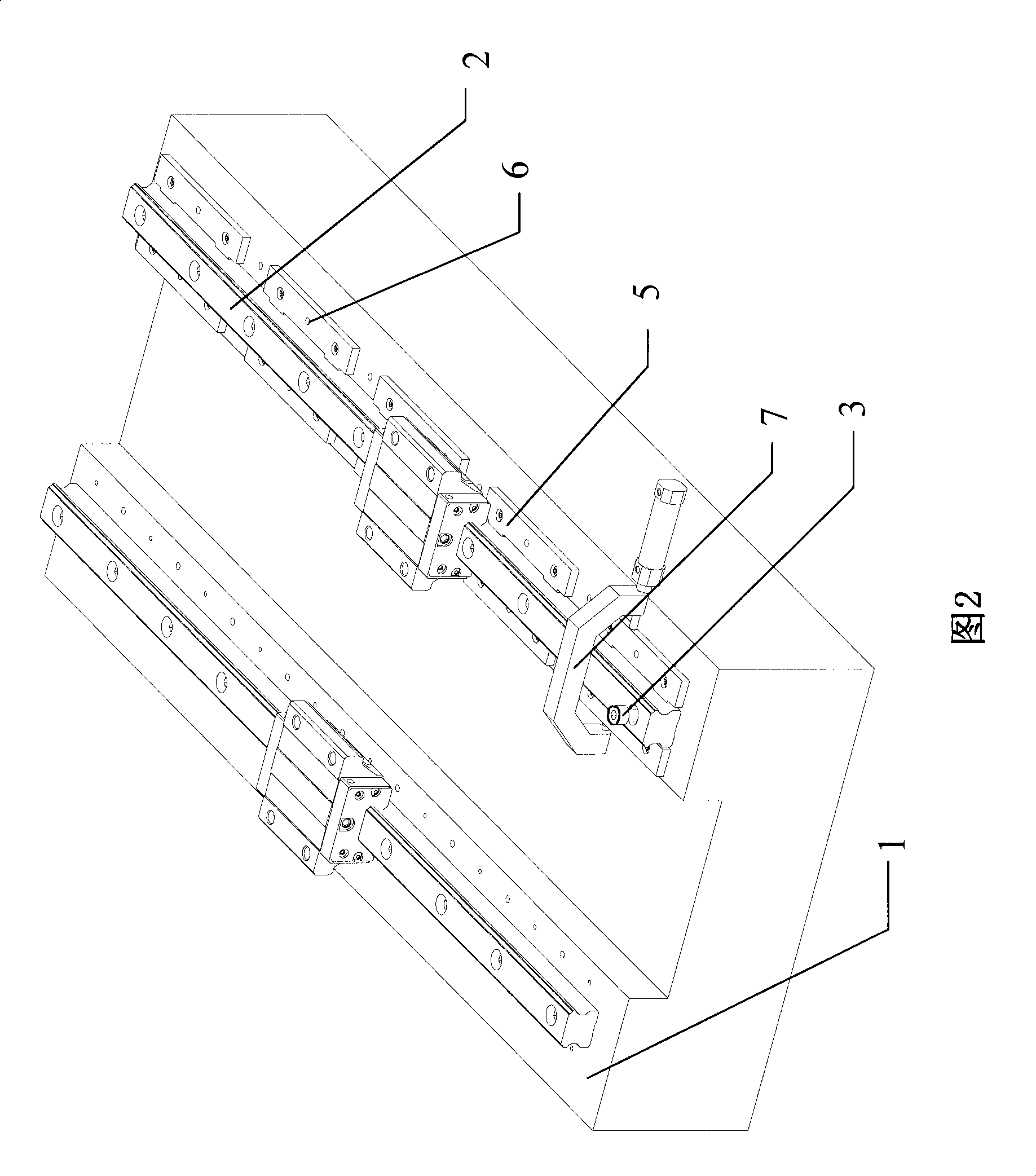

[0022] The positioning and clamping method of a linear guide rail as shown in Figure 2 mainly involves the installation base 1, the track 2, and the track fixing screws 3. The special feature is that firstly, the track 2 is installed on the corresponding Reserve the position, and adjust the straightness and mutual parallelism of each track at the same time; after that, lock the track 2 through the track fixing screw 3; then, attach the upper clamp block 5 on both sides of the track 2; then, provide the The clamping stress makes the clamping blocks close to both sides of the track, and the symmetrical clamping blocks 5 on both sides of the track 2 are sequentially locked with screws, and the pins 6 are used to position the clamping blocks 5, so that the clamping stress of the clamp 7 becomes that of the clamping block 5. Clamping force; finally withdraw the fixture 7, so that the clamping force of the clamping block 5 becomes the fixed pre-tightening force of the track 2. In or...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com