Series cab signal two-way receiver coil

A technology for receiving coils and locomotive signals, which is applied in the directions of vehicle route interaction equipment, railway signals, railway signals and safety, etc., can solve the problems of disordered, unbalanced, normal signal interference of the receiving coil waveform, and improve the ability to resist electrical interference, Easy to use, maintain and repair, and improve the effect of impact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

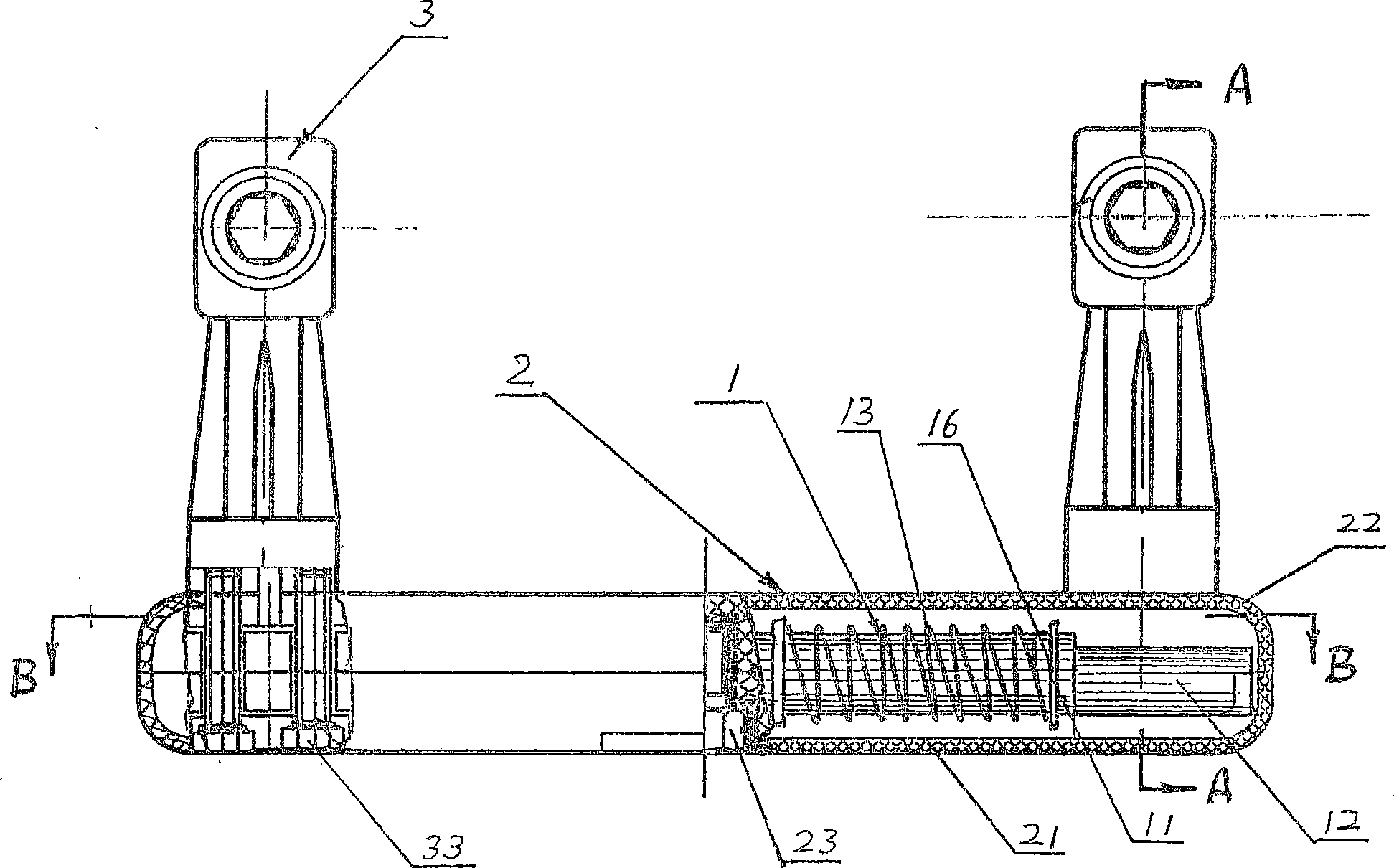

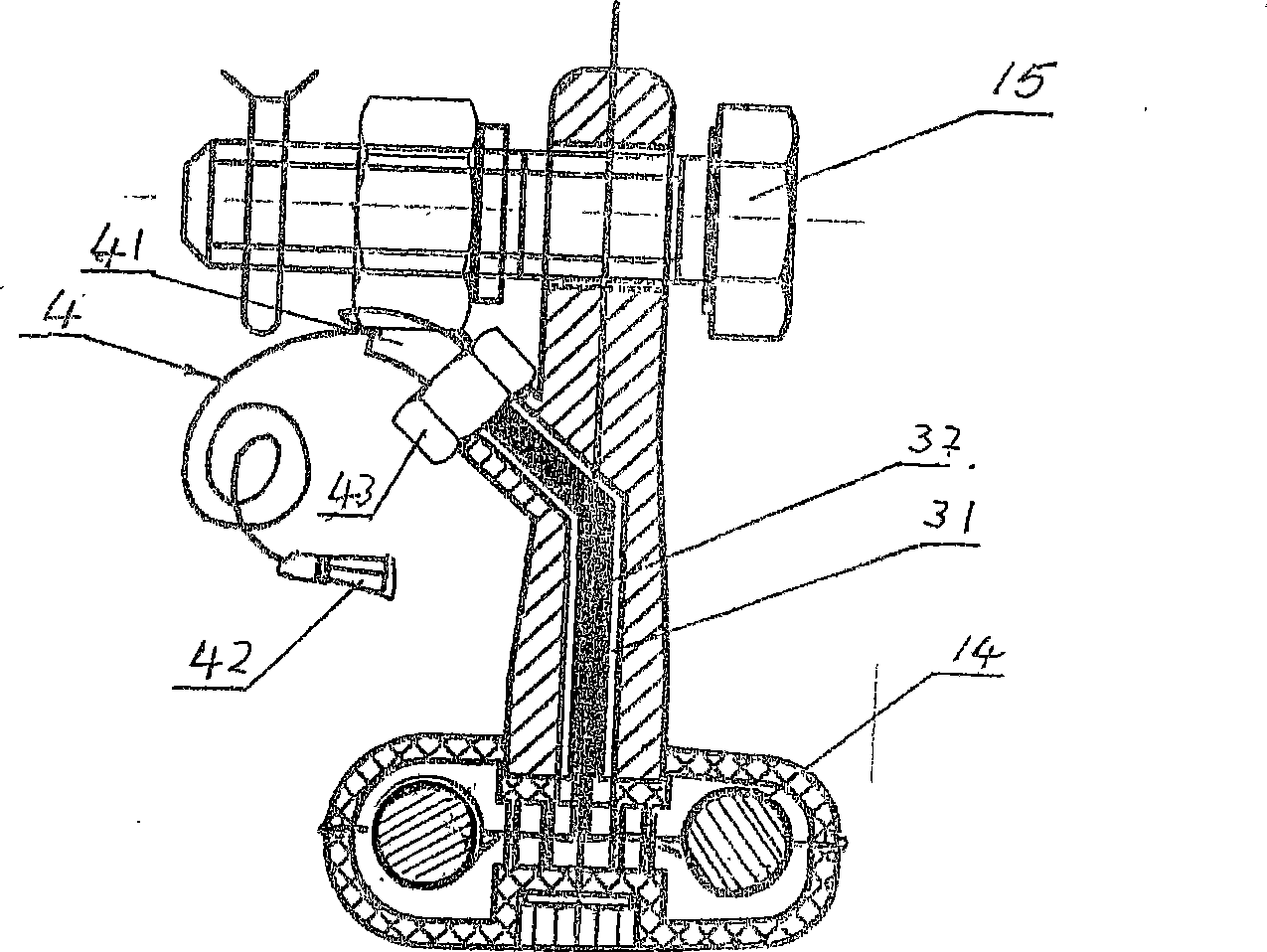

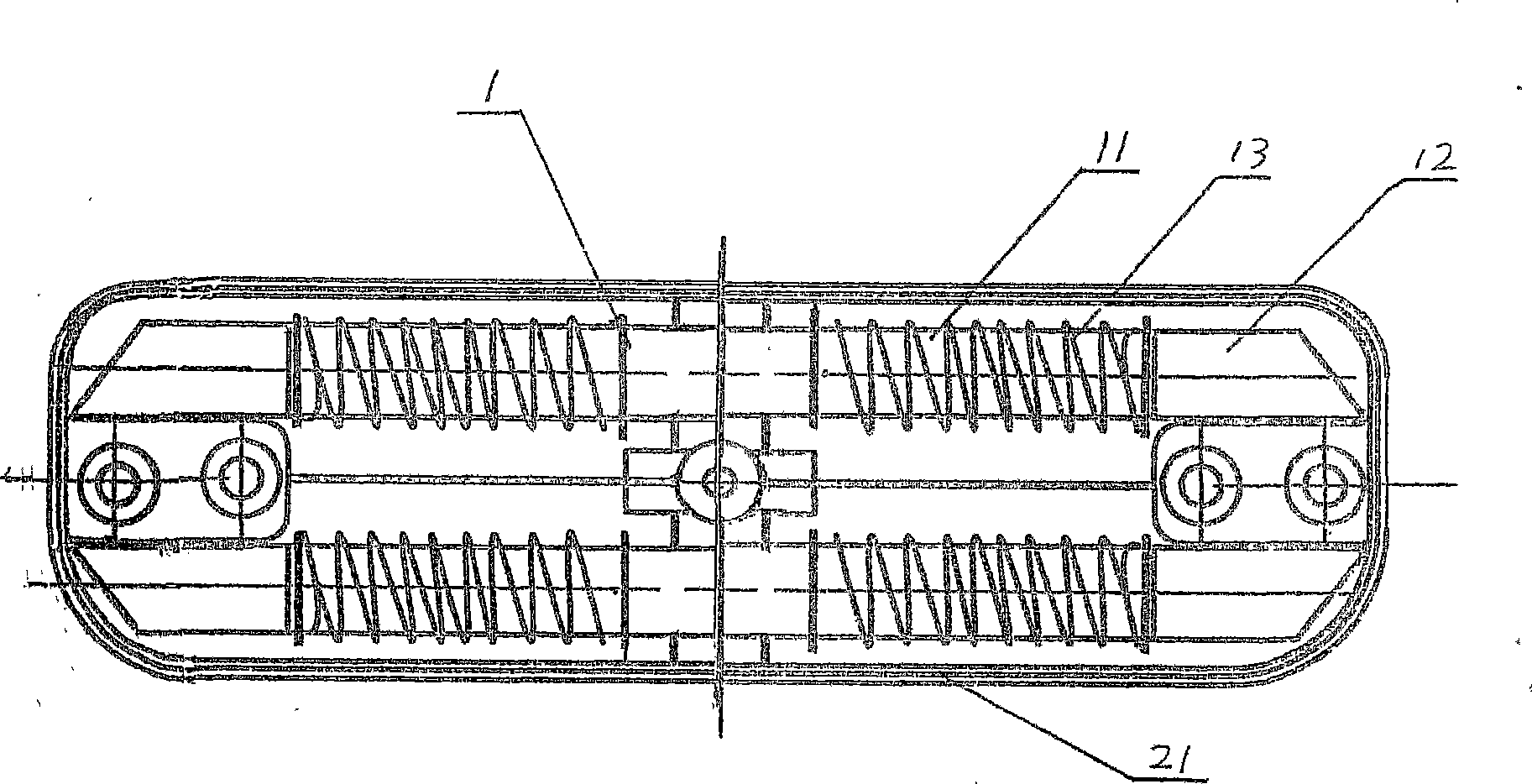

[0015] Depend on figure 1 , figure 2 and image 3 Shown, a series of locomotive signal two-way receiving coils are mainly composed of balanced two-way receiving coils 1, glass fiber reinforced plastic shells 2, precision cast steel hangers 3 and two-core shielded cable lead wires 4, wherein: The main magnetic core 11 and the auxiliary magnetic core 12 with low magnetic permeability are both bonded and fixed to form the magnetic core of the balanced dual-circuit receiving coil 1, the coil winding 13 is arranged on the magnetic core, and the epoxy resin glue 14 is used to seal the coil winding 13 and Limiting ring 16, its two sets of coils are arranged parallel to each other in the lower casing 21 of the FRP casing 2, the lower casing 21 is screwed with the upper casing 22 of the FRP casing 2 through the connecting piece 23, and epoxy resin is used between the two. Glue 14 is sealed, and the glass fiber reinforced plastic shell 2 equipped with the balanced two-way receiving c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com