Stretching device of case beam in case

A tensioning device and box girder technology, which is used in construction, building construction, and building material processing to achieve the effects of high stability, construction safety, and simple construction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in further detail below in conjunction with examples and with reference to the accompanying drawings.

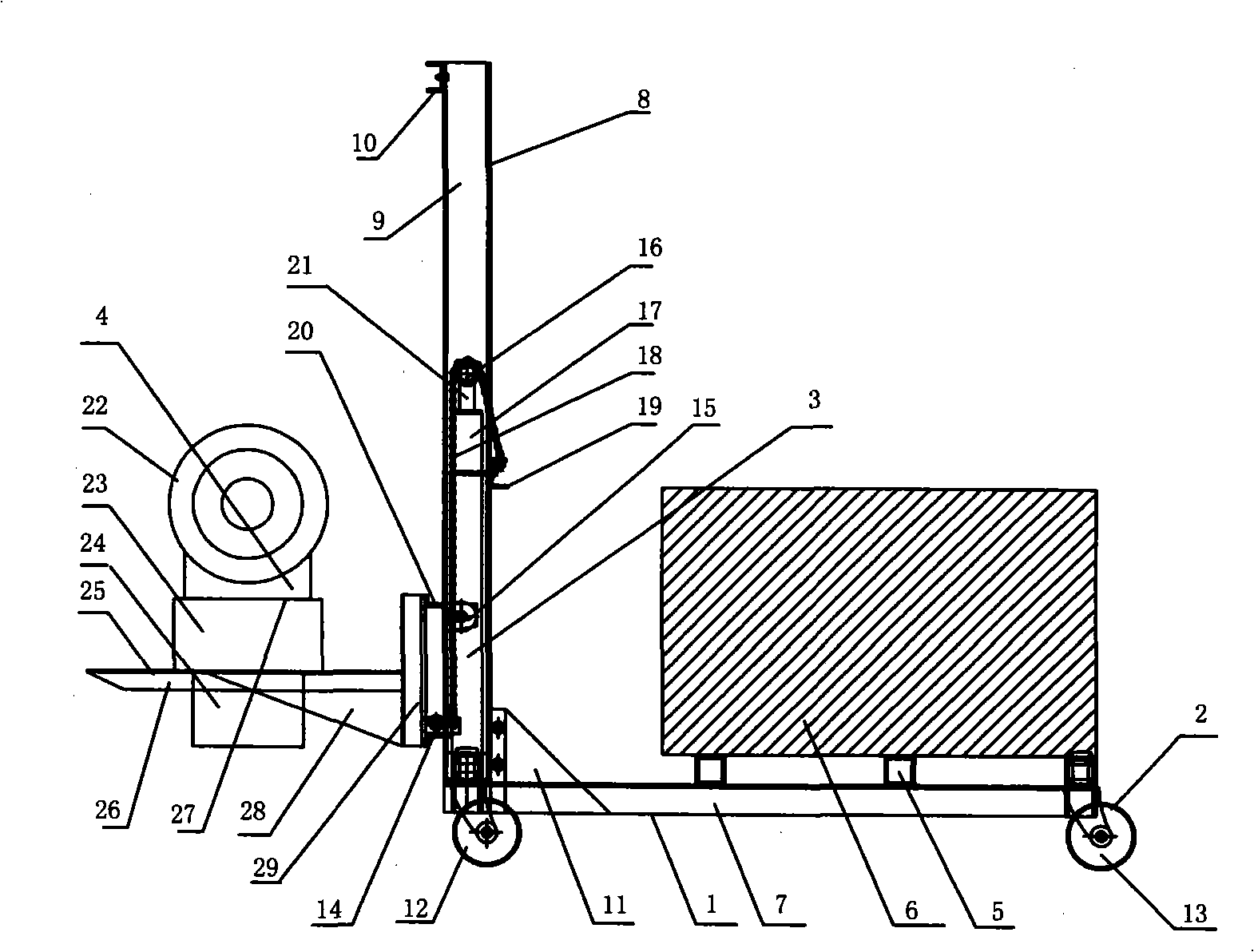

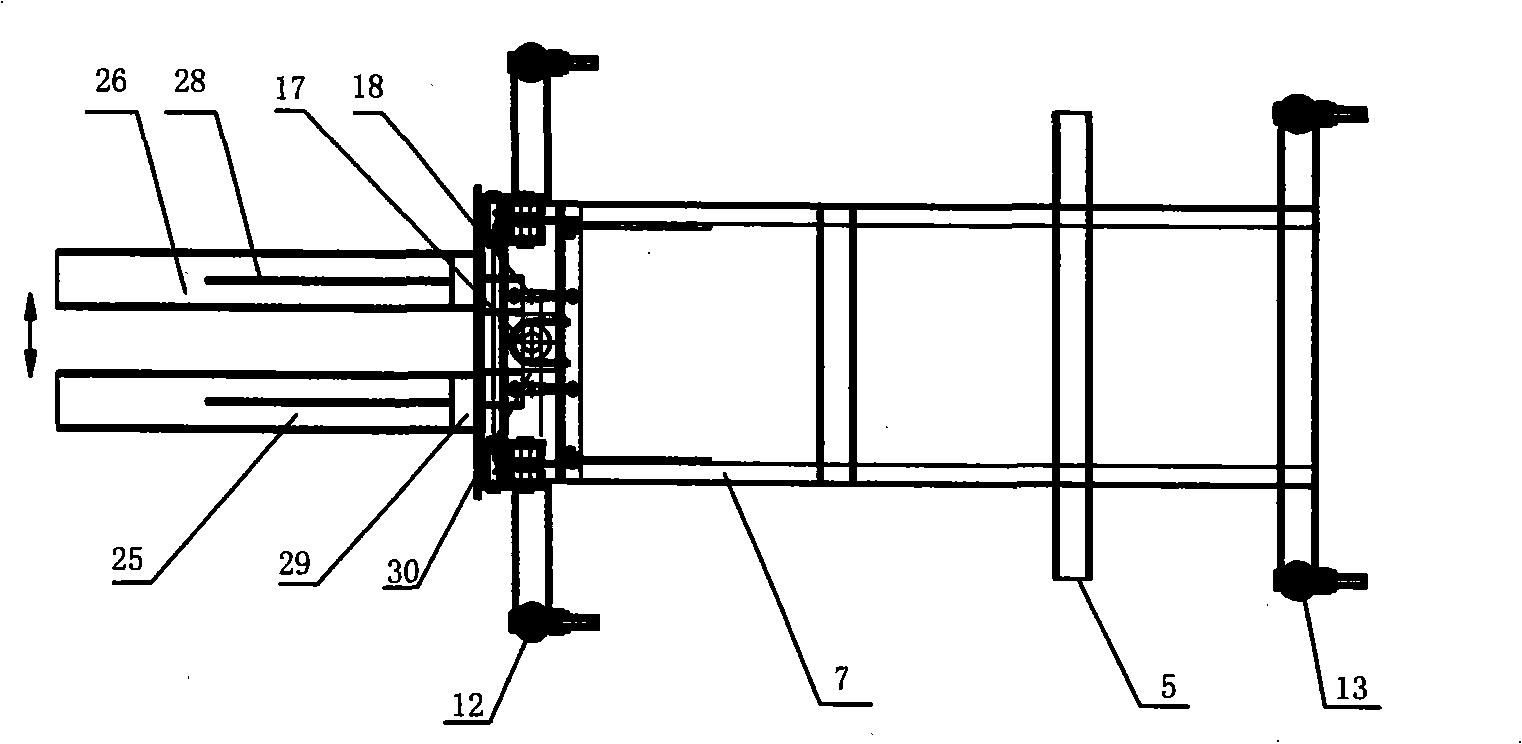

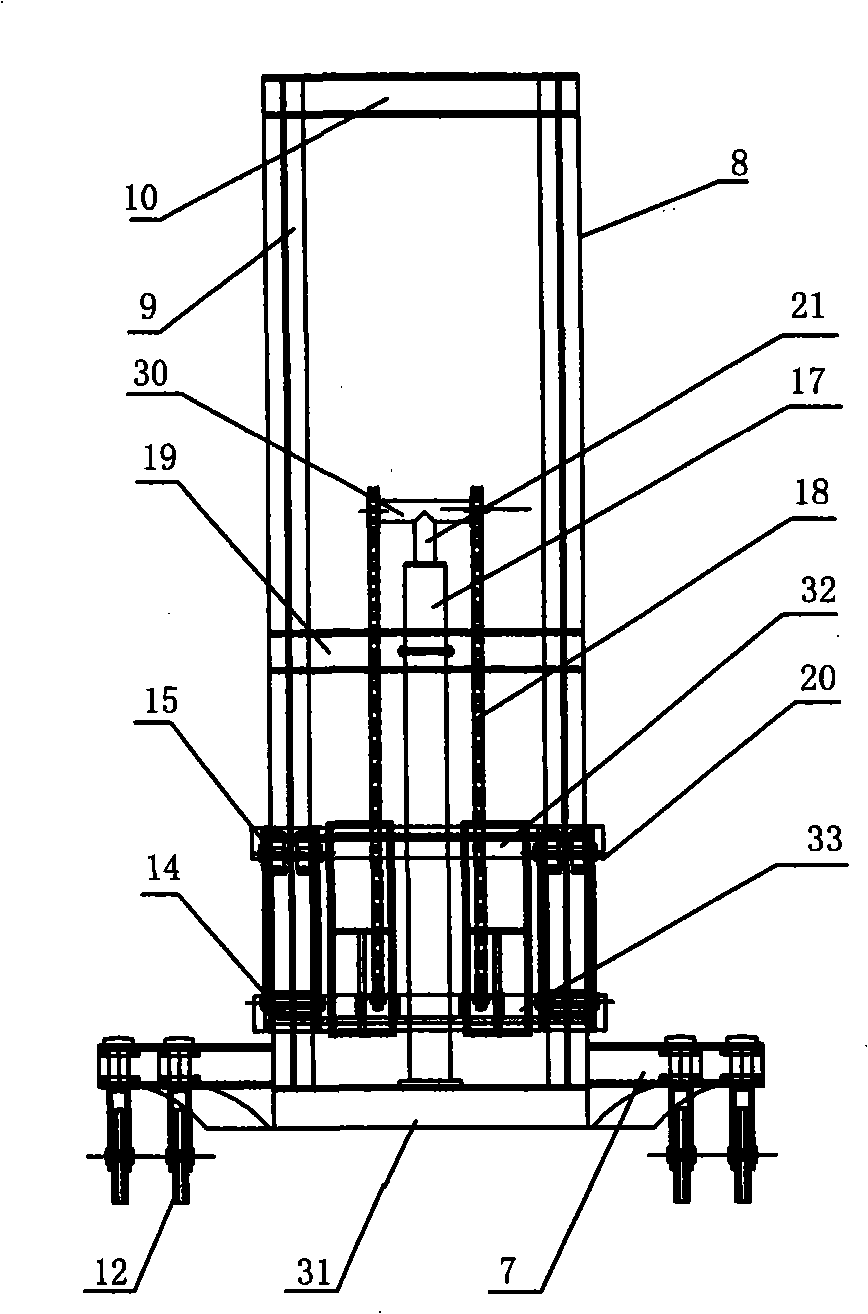

[0029] The present invention is composed of a main structure system 1, a running system 2, a lifting system 3 and a load-bearing system 4, wherein:

[0030] The main structure system 1 is an "L"-shaped steel structure composed of plane trusses 7 and vertical trusses 8. A beam 5 is fixed at the middle and rear end of the plane truss 7, and a balance weight 6 is set on the beam 5. The mass ratio of the jack 22 to the balance weight 6 is 1:0.65-0.85. The vertical truss 8 is composed of two vertical slide bars 9 arranged in parallel, and a limit beam 10 for preventing the lifting system 3 from falling is installed on the top of the two vertical slide bars 9 of the vertical truss 8 . A stiffening steel plate 11 is fixed between the plane truss 7 and the vertical truss 8 of the main structure system 1, the plane truss 7 is a channel ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com