Fuel cell assembly using multiple fuel cell stacks and control method therefor

一种燃料电池堆、燃料电池的技术,应用在燃料电池分组、燃料电池、燃料电池助剂等方向,能够解决制造及工作成本增加等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

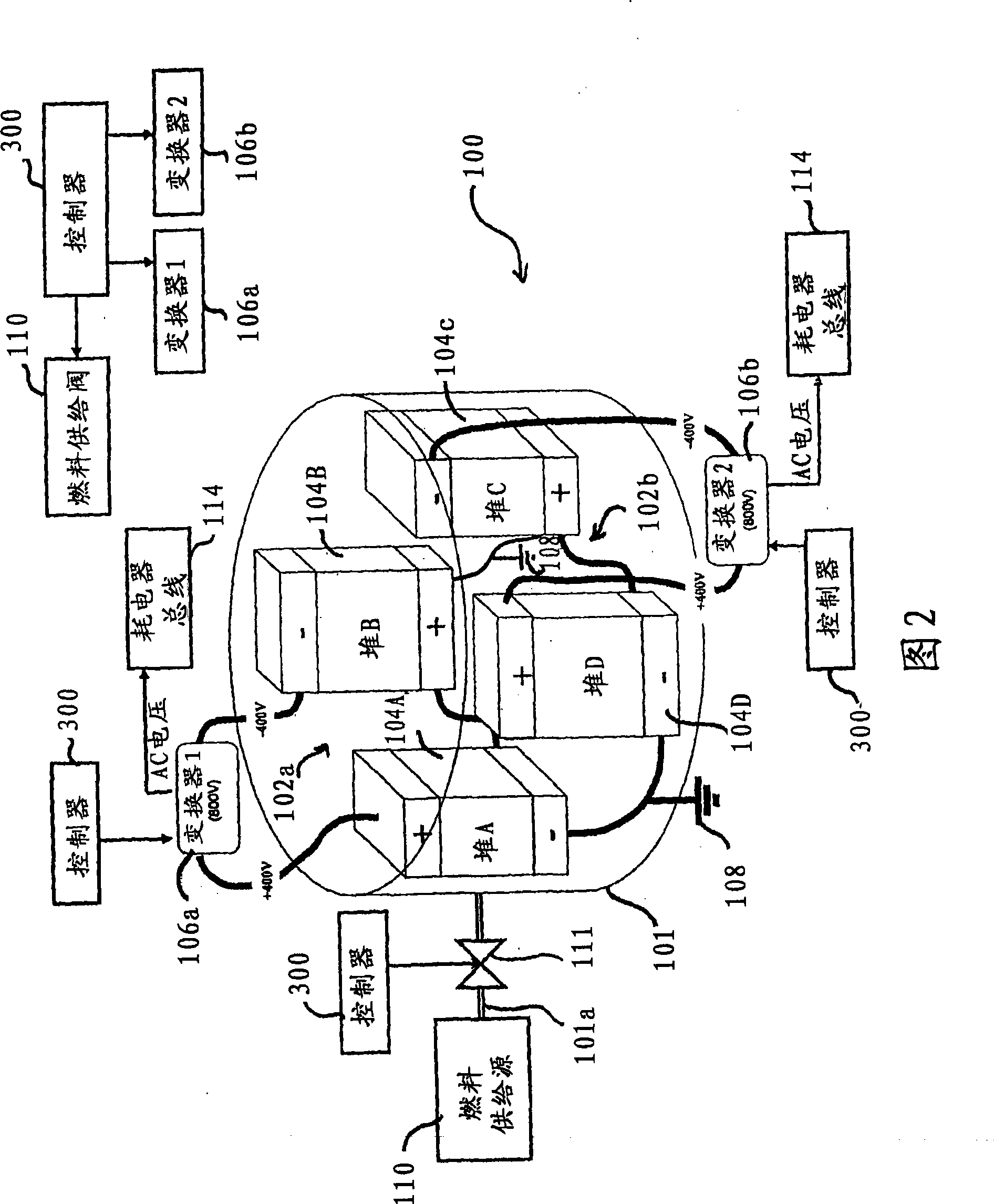

[0023] Figure 2 shows a multi-stack assembly that receives fuel from a fuel supply source and generates power for load consumption, the assembly includes a plurality of fuel cell stack groups, each stack group includes at least one fuel cell stack, and corresponding to the fuel cell stack A plurality of inverters of a group, each inverter draws a predetermined amount of DC power from a corresponding group of fuel cell stacks and converts the DC power to AC power. The multi-stack assembly also includes a controller for controlling the inverters to draw a predetermined amount of DC power from the corresponding fuel cell stack group to meet the power demand of the load.

[0024] As shown in FIG. 2, the multi-stack assembly includes a plurality of fuel cell stack pairs 102a-b, wherein each stack pair 102a-b includes two fuel cell stacks 104A-D connected in series with each other, and a plurality of 102a-b draws DC power and converts the DC power to an AC power converter 106a-b, wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com