Machine tool, sensor module, and measuring method

A technology of sensor components and measurement methods, applied in the direction of measuring devices, measuring/indicating equipment, metal processing machinery parts, etc., can solve the problems of arm obstacles, inability to install arms, and difficulty in miniaturization of turret lathes, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

[0082] A turret lathe as an example of a machine tool in Embodiment 1 of the present invention will be described in detail with reference to the drawings.

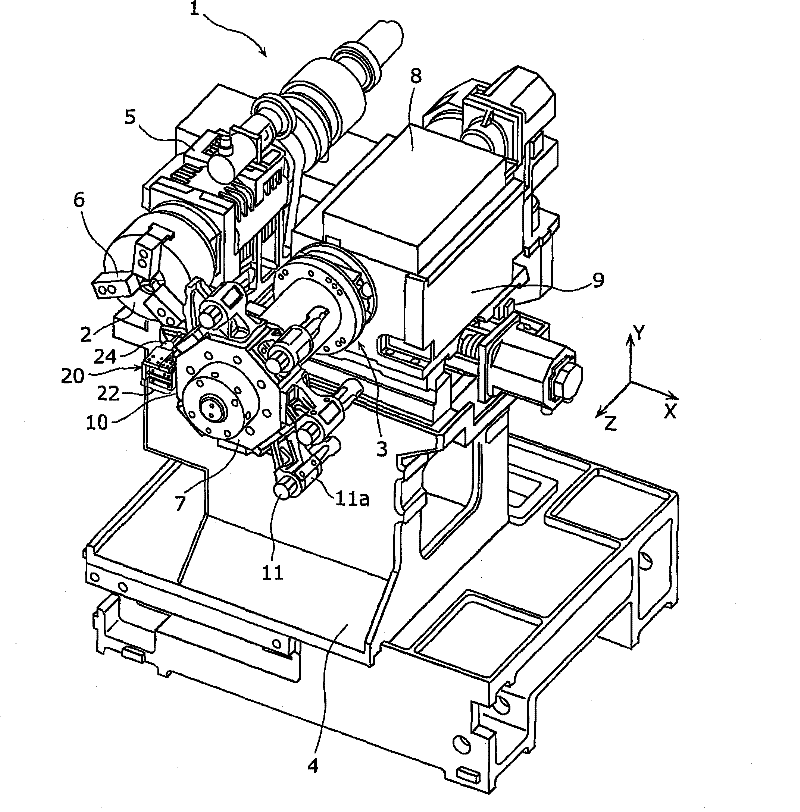

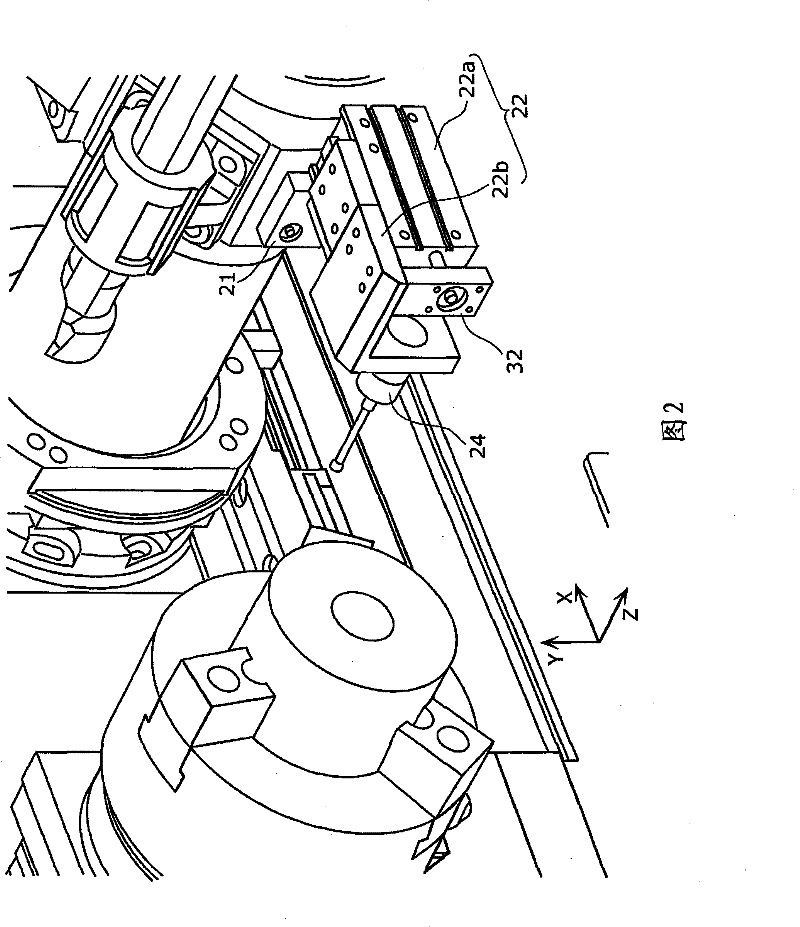

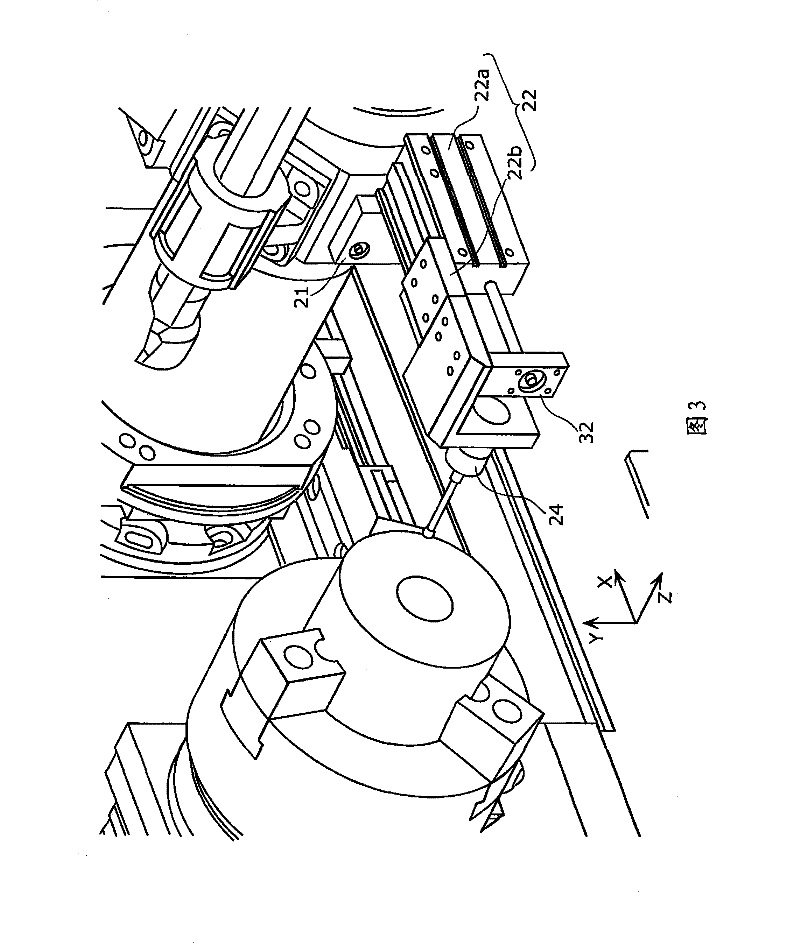

[0083] First, use Figure 1 ~ Figure 3 The configuration of the turret lathe according to Embodiment 1 will be described.

[0084] figure 1 It is a perspective view showing the appearance of the turret lathe according to Embodiment 1 of the present invention.

[0085] like figure 1 Shown, the basic composition of turret lathe 1 and Figure 21 The shown conventional general turret lathe 200 is similarly equipped with a spindle 2 for gripping and rotating a workpiece, a turret 3 which is a rotary tool selection mechanism, and the like.

[0086] However, the turret lathe 1 further includes a sensor unit 20 as a characteristic component.

[0087] The sensor unit 20 has a support 22 that expands and contracts in the radial direction of the turret 7 and a sensor 24 for measuring the dimensions of the workpiece, and is capa...

Embodiment approach 2

[0157] As Embodiment 2 of the present invention, a turret lathe 100 having a sensor unit 120 capable of expanding and contracting a sensor distance by turning an arm 122 provided with a sensor 24 at an end will be described. The turret lathe 100 is another example of the machine tool of the present invention.

[0158] In addition, the basic configuration of the turret lathe 100 of the second embodiment is the same as that of the turret lathe 1 of the first embodiment. Therefore, in Embodiment 2, the description will be centered on the sensor unit 120 as a characteristic component.

[0159] First, use Figure 8 ~ Figure 11 , the basic configuration of the sensor unit 120 in the second embodiment will be described.

[0160] Figure 8 It is an enlarged perspective view showing the appearance of the sensor unit 120 in Embodiment 2 of the present invention.

[0161] The sensor unit 120 has: a base 121, a rotating arm 122 mounted on the base 121, a gear box 123 integrally rotating...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com