Radar bearing performance test bench

A bearing performance, test bench technology, applied in the workbench, radio wave measurement system, loading/unloading, etc., can solve the problems of affecting the detection effect, complex use of radar bearings, and lack of reliability in detection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

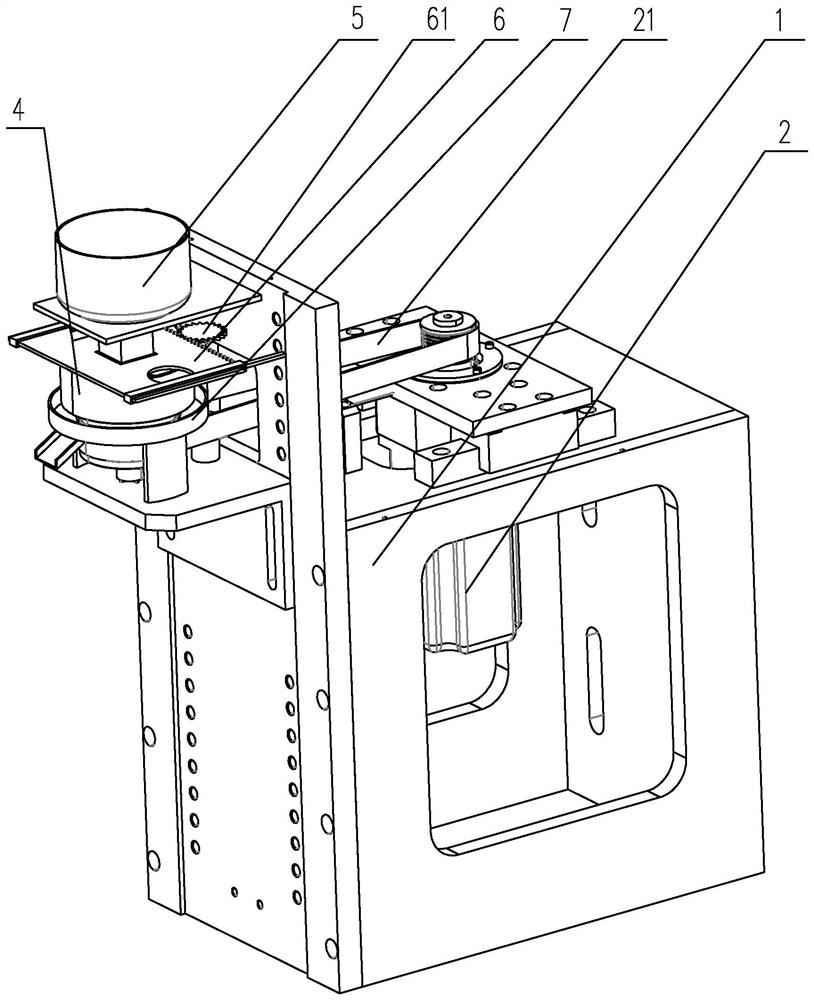

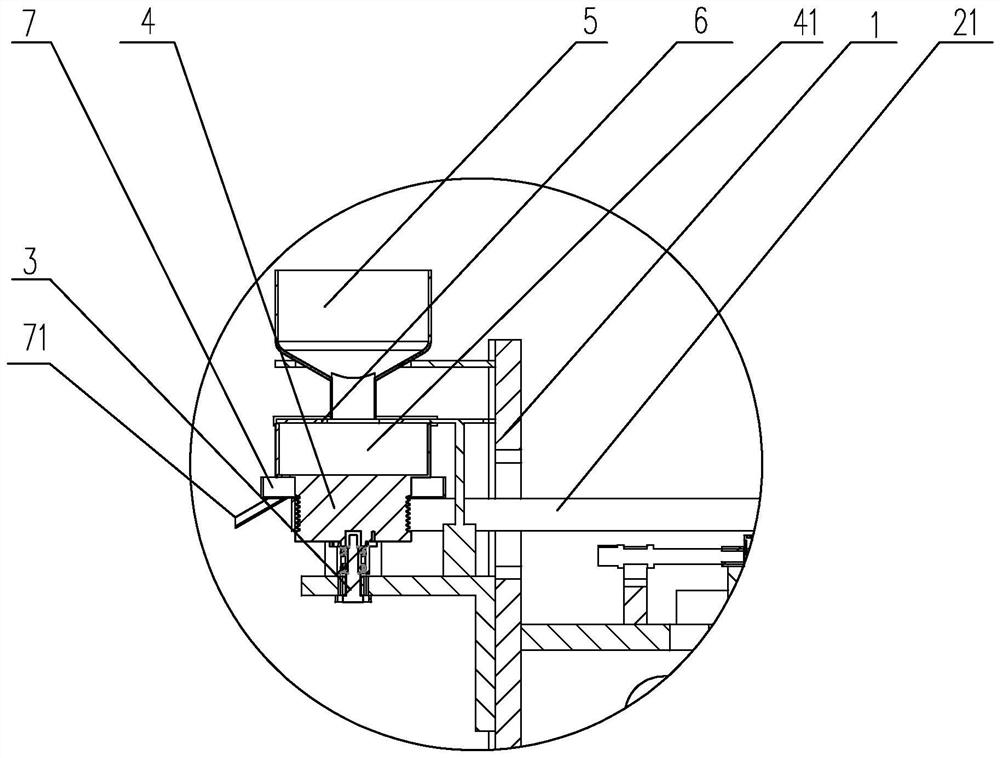

[0018] The embodiment of the radar bearing performance test bench of the present invention is as follows Figure 1 to Figure 2 Shown: including a frame body 1, the frame body 1 is provided with a mounting shaft 3 for connecting with the inner ring of the bearing to be tested, and the mounting shaft 3 is provided with a bearing seat 4 for connecting with the outer ring of the bearing to be tested, The frame body 1 is provided with a drive motor 2, and the output end of the drive motor 2 is connected to the bearing seat 4 through a pulley 21. The bearing seat 4 is provided with a bearing slot 41, and the frame body 1 is in the bearing slot 41. A material-carrying barrel 5 is arranged above, and the material-carrying barrel 5 carries steel balls of the same quality and size, and a discharge port is provided on the material-carrying barrel 5, and the material-carrying barrel 5 and the bearing groove 41 are slidably arranged There is a baffle 6 used to block the discharge port, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com