Boxing machine

A cartoning machine and box-packing technology, applied in packaging, packaging bottles, transportation and packaging, etc., can solve the problems of low work efficiency and inability to realize automatic boxing, etc., achieve convenient boxing, save labor resources, and increase production speed Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

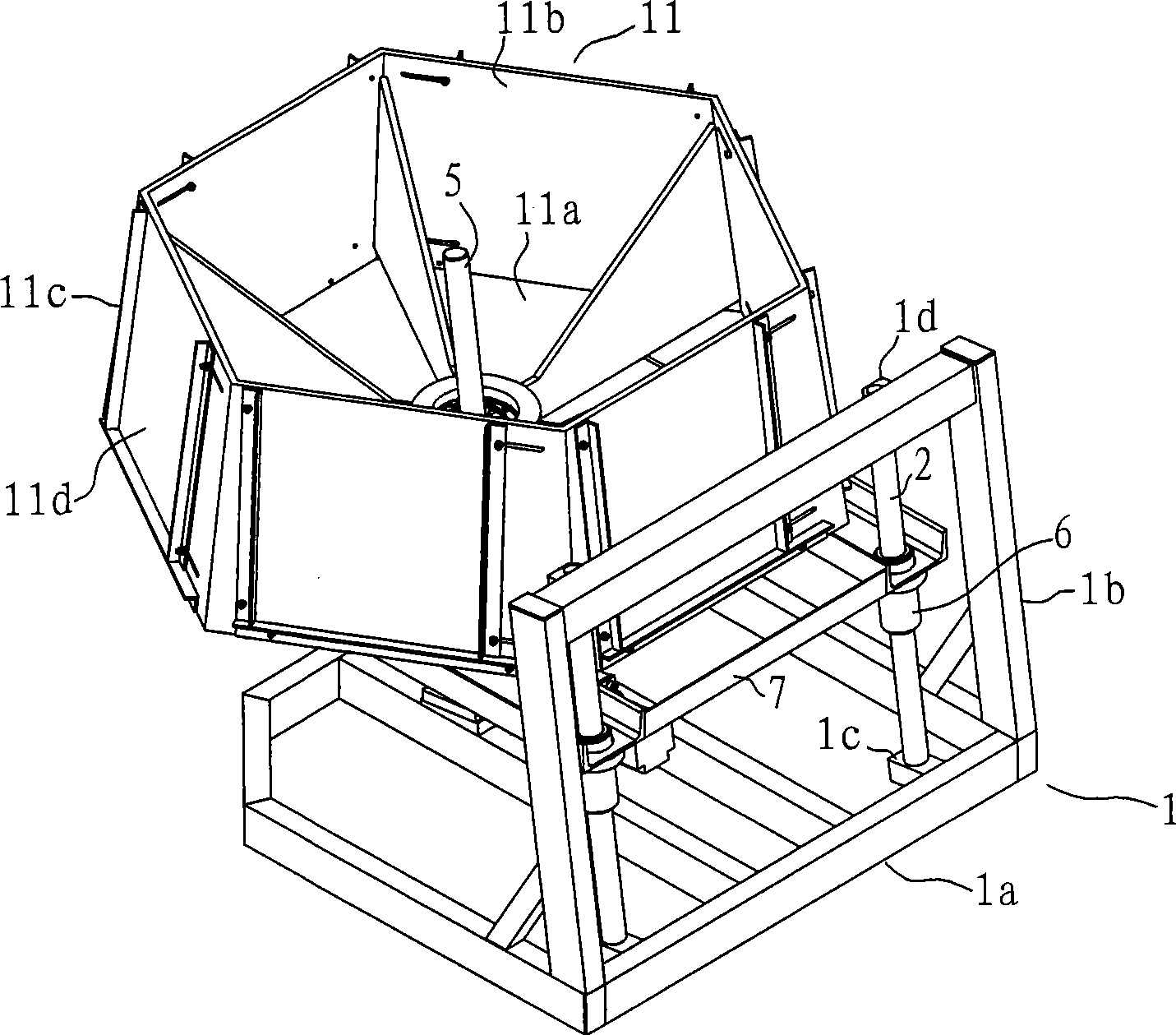

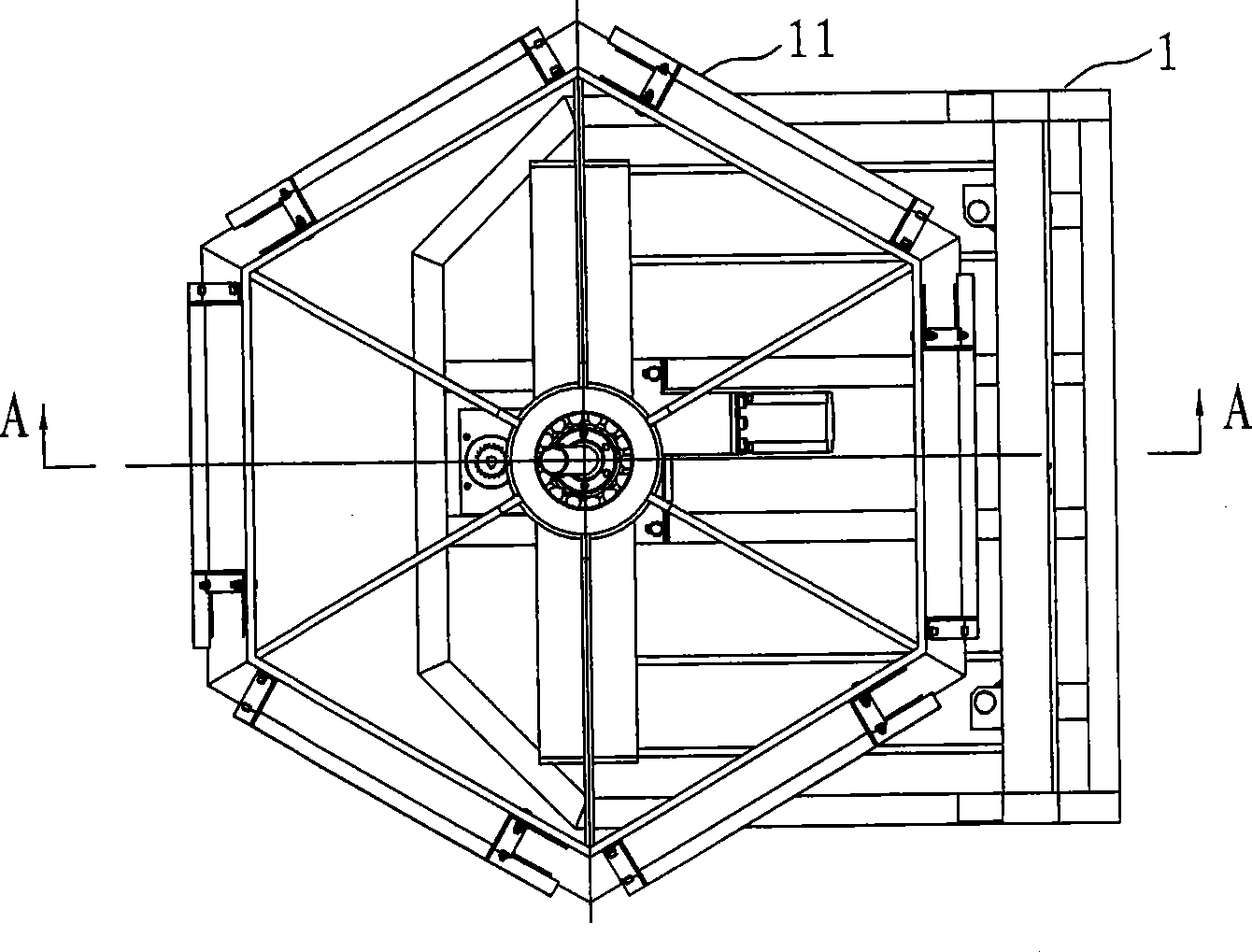

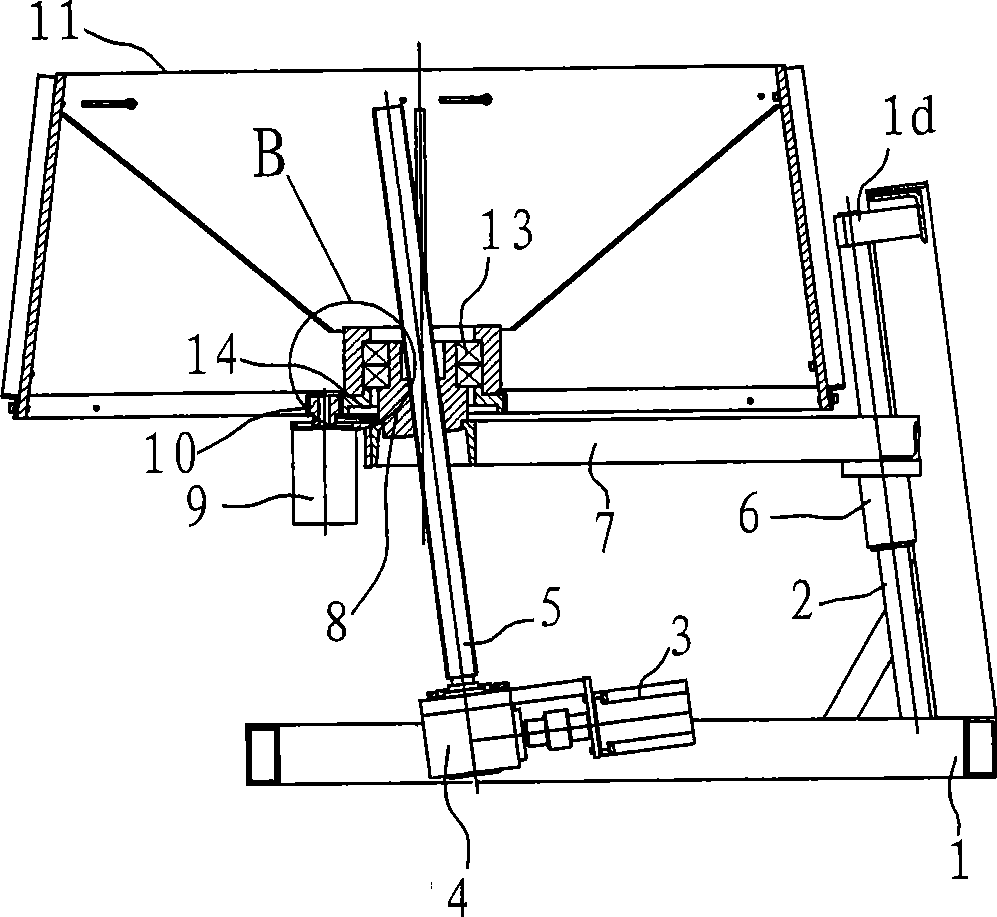

[0027] Example: Reference figure 1 , figure 2 and image 3 As shown, the cartoning machine in this embodiment includes a frame 1, a bracket 7, a guide column 2, a turntable 11, a first motor mechanism, a screw shaft 8, a lead screw 5 and a second motor mechanism.

[0028] refer to image 3 As shown, the frame 1 is roughly L-shaped, including a bottom frame part 1a and a support part 1b arranged on the bottom frame part 1a, and the bracket 7 is arranged on the frame 1 in a liftable manner through the guide column 2, and the bracket 7 is parallel It is arranged on the bottom frame part 1a; the guide columns 2 are two in parallel, and the outer walls of the guide columns 2 are provided with guide sleeves 6, and the guide sleeves 6 are fixed on both sides of the bracket 7. The bottom end of the guide column 2 is fixed on the cushion block 1c of the bottom frame part 1a, and the top end is fixed on the mounting block 1d of the support part 1b.

[0029] The packaging box 21 can...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com