Automatic low-frequency low-voltage load-reducing centralization optimization control system

A low-frequency, low-voltage, optimized control technology, applied in information technology support systems, power network operating system integration, AC network voltage adjustment, etc., can solve problems such as system crashes, increased frequency recovery time, single action parameters, etc., to reduce Effects of over-cut or under-cut, improved stability, and improved economy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The embodiments of the present invention are described in detail below in conjunction with the accompanying drawings: this embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation methods and specific operating procedures are provided, but the protection scope of the present invention is not limited to the following the described embodiment.

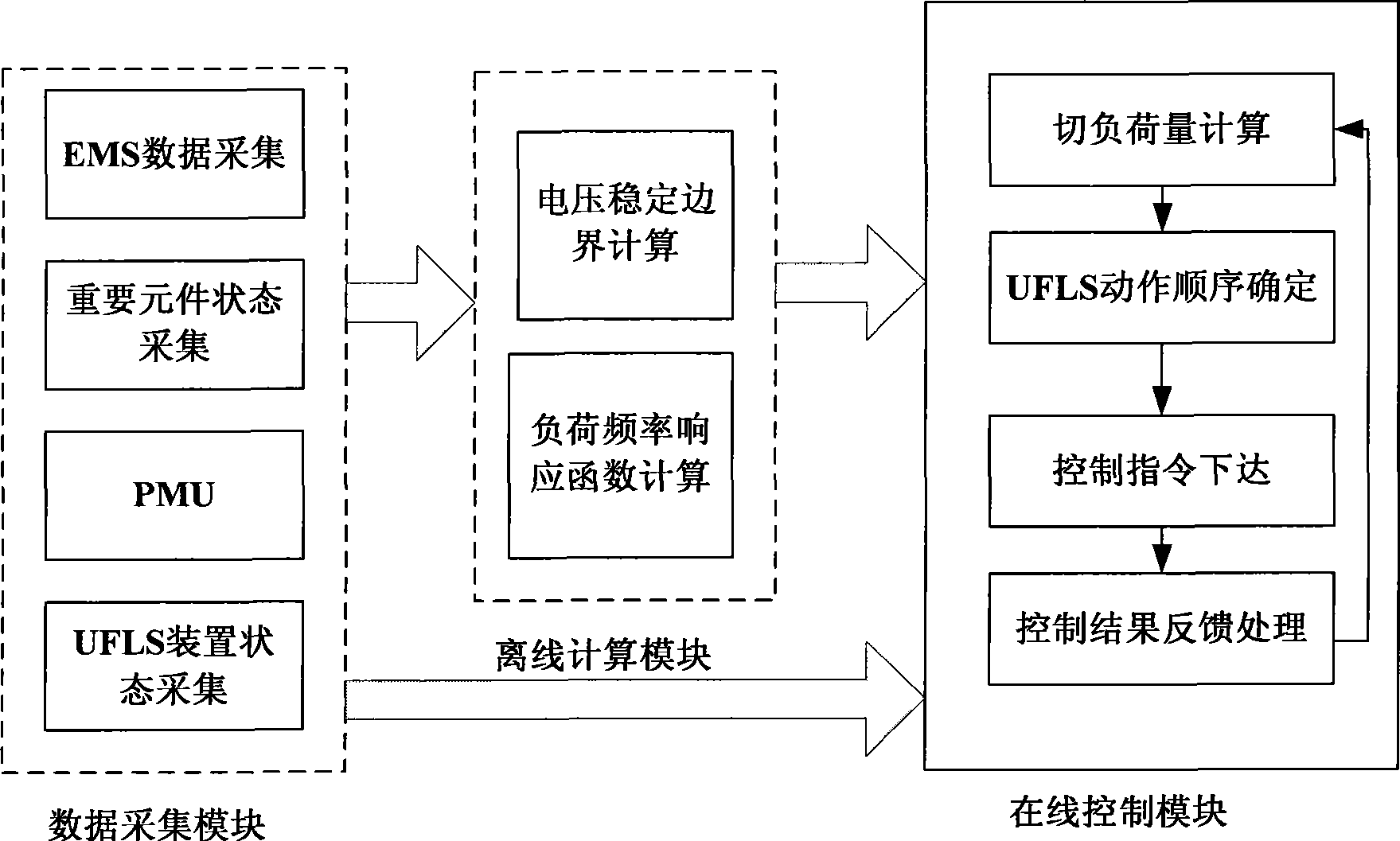

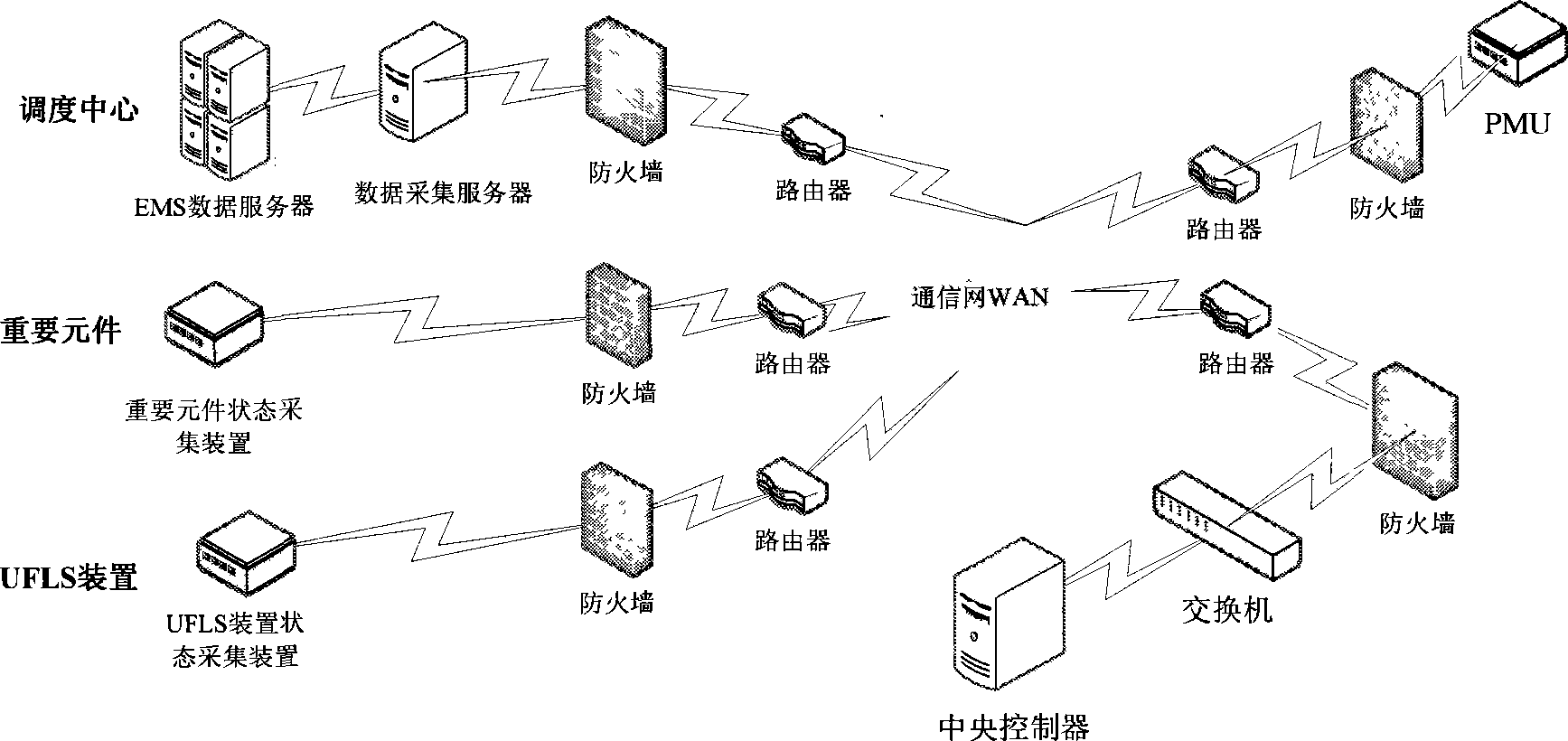

[0023] Refer to attached figure 1 , the power system automatic low-frequency low-voltage low-voltage load shedding centralized optimization control system involved in this embodiment includes: a data acquisition module, an offline calculation module, and an online control module, wherein:

[0024] The data acquisition module collects EMS data through the data server, and collects the current, voltage, frequency, load and other operating information of the system through the data acquisition device installed at the PMU, UFLS device, and important components, as well as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com