Wooden lattice girder for construction

A lattice beam and field technology, applied in the field of wooden lattice beams used in the construction field, can solve the problems of high production cost, difficult tongue and groove and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

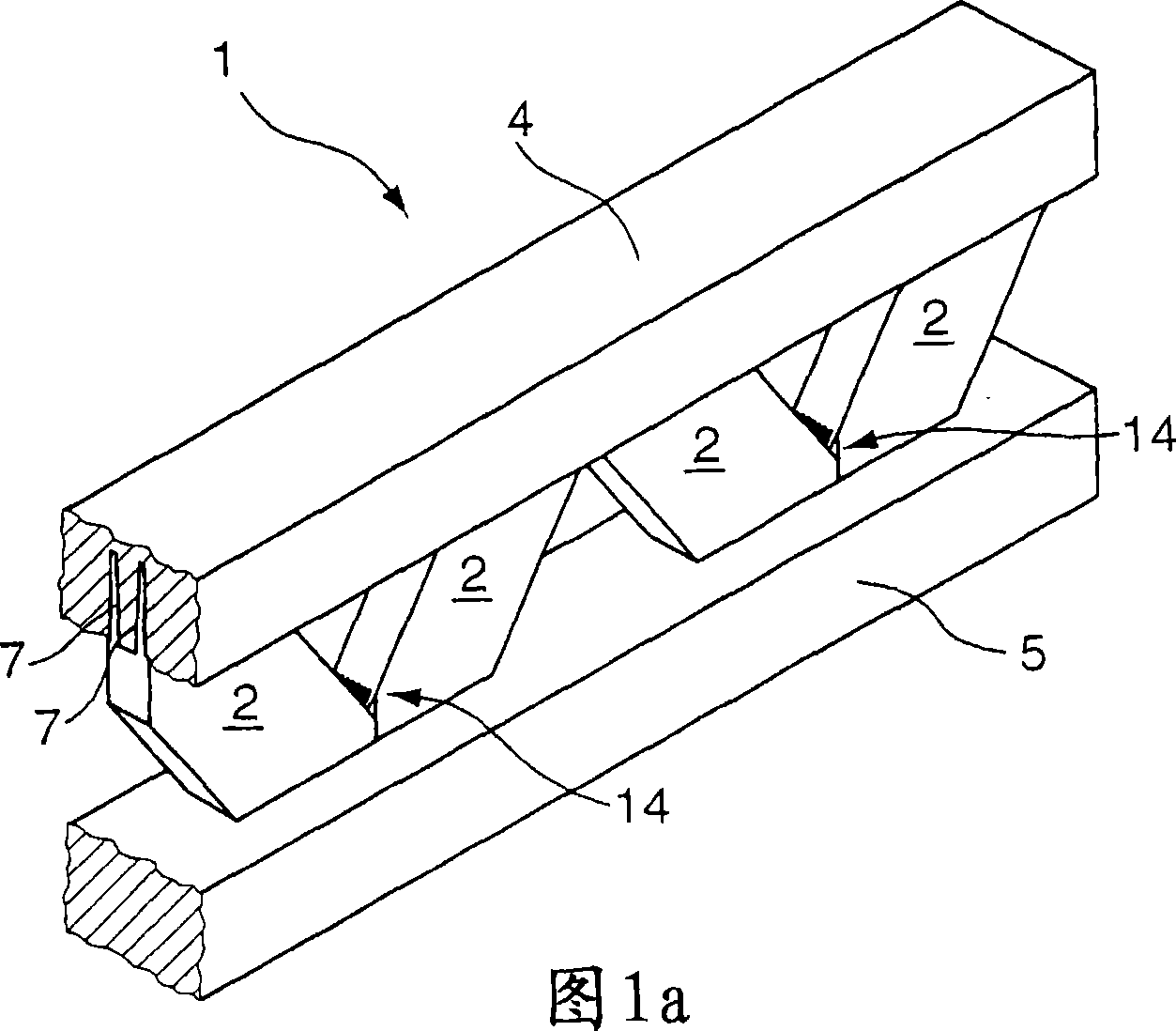

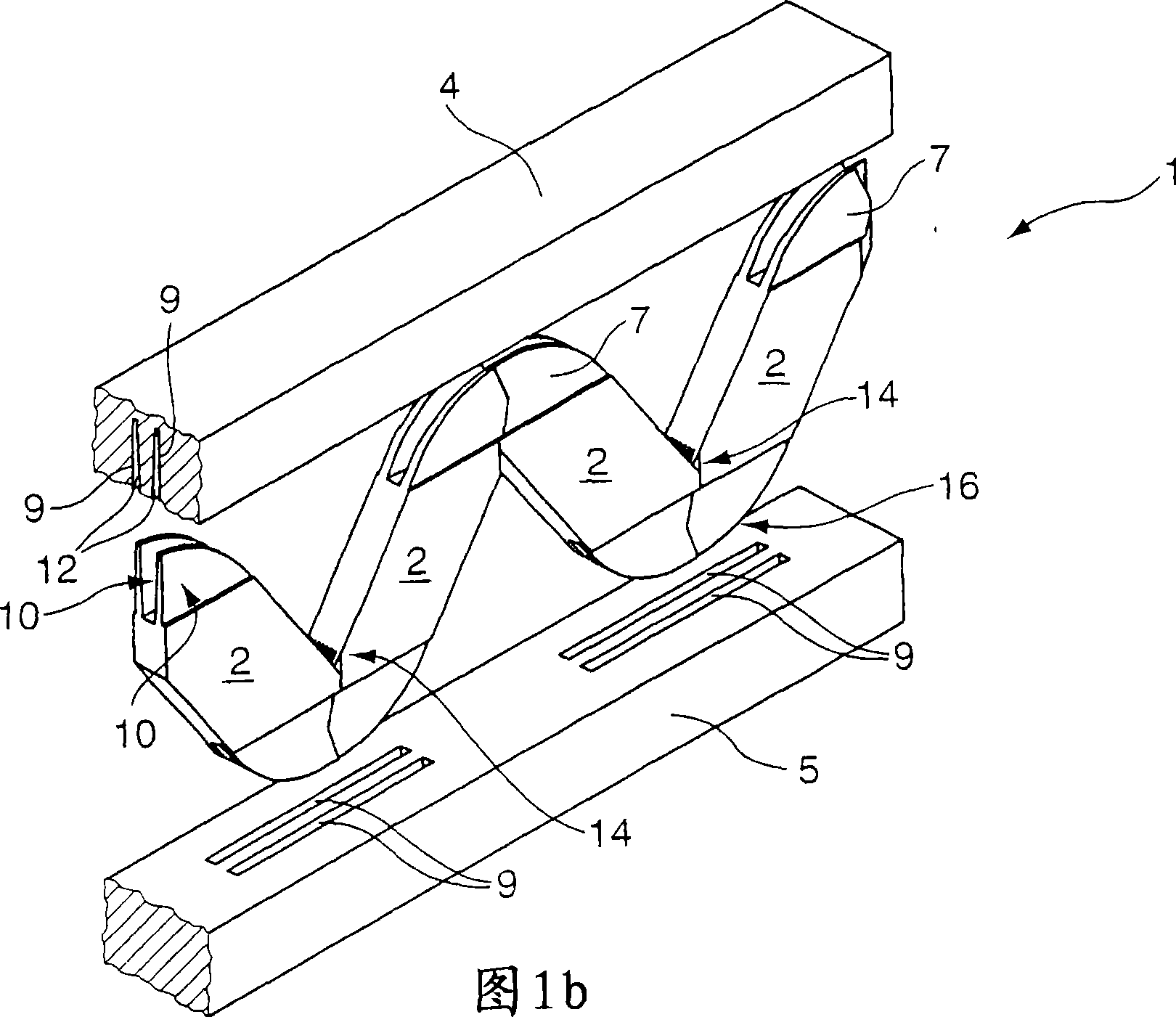

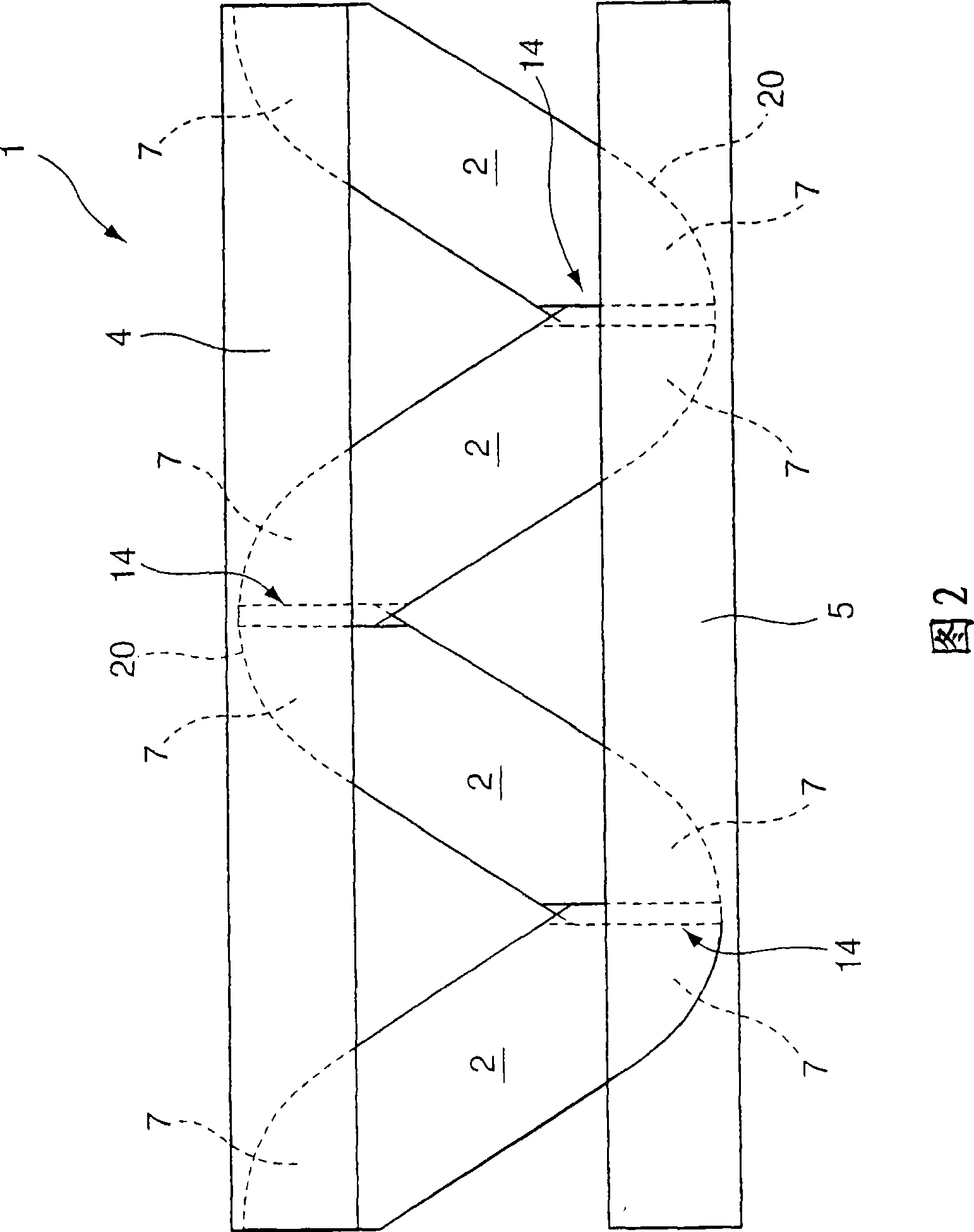

[0029] Figure 1 shows a part of the lattice beam of the present invention. Figure 1a shows the parts in an assembled state, and Figure 1b shows an exploded view of the parts.

[0030] The lattice beam 1 has dimensions commonly used in the construction industry for lattice beams of this type. The lattice beam 1 is several meters long and its supports 2 and stringers 4, 5 are several centimeters thick. The lattice girder 1 has an upper run 4 and a lower run 5 . The two string beams 4 , 5 are connected to each other by the supports 2 . The support 2 is positioned obliquely to the string beams 4, 5 and forms an angle of approximately 45° between the support 2 and the string beams 4, 5. The supports 2 each have two tenons 7 at their ends. The string beams 4 and 5 are provided with tenon grooves 9 extending longitudinally thereof, and each tenon groove 9 is matched with a tenon 7 . In the assembled state each tenon 7 is glued into an associated tenon groove 9 . The tenon 7 at ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com