Valve driving device

A technology of valve drive and power transmission device, applied in the direction of valve device, valve operation/release device, valve details, etc., can solve the problem of surplus products, etc., and achieve the effect of reducing switching work and low introduction cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

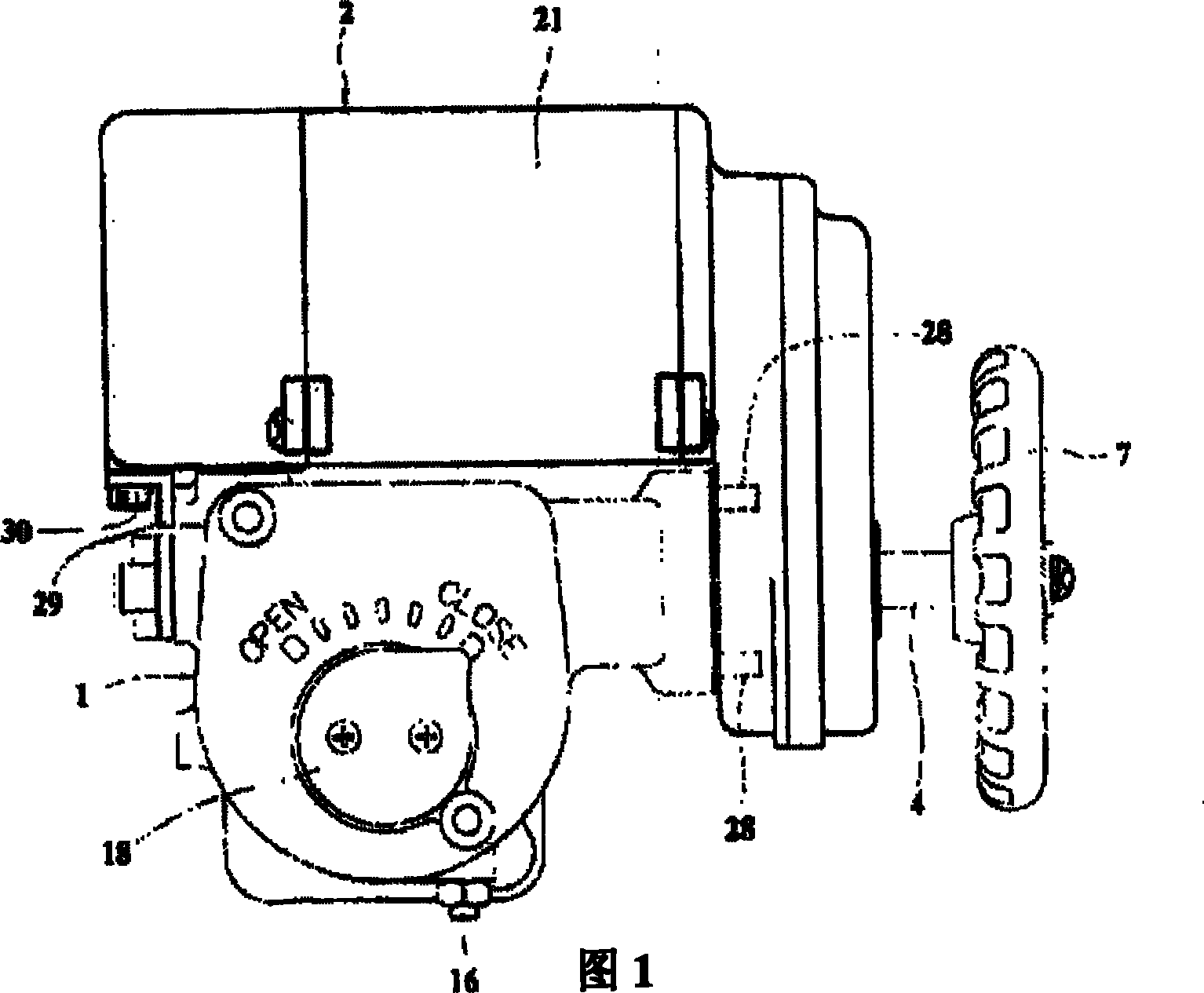

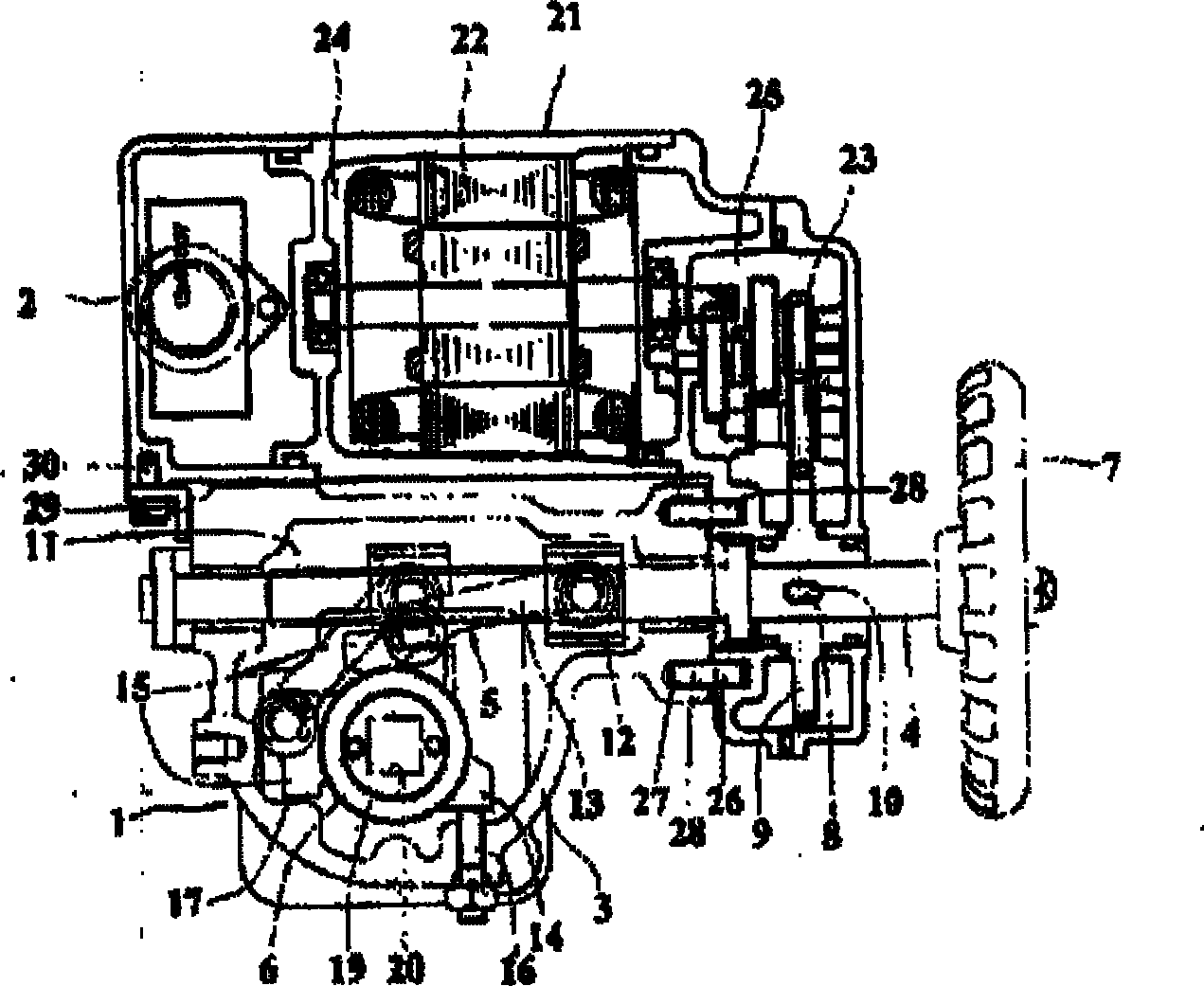

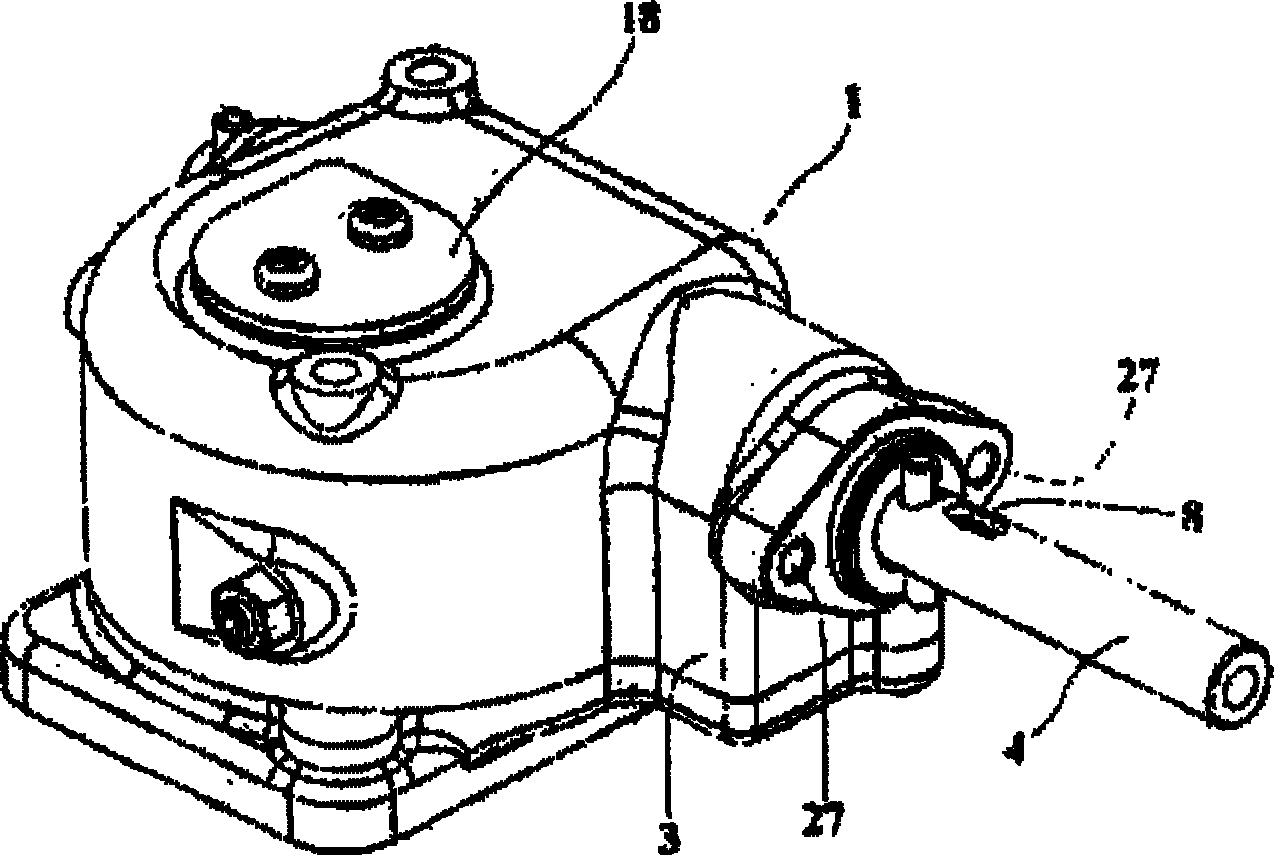

[0069]Preferred embodiments of the present invention will be described in detail below. Referring to Figures 1-4, (1) is the basic assembly, (2) is the additional assembly added to the basic assembly as necessary, by adding additional assemblies to the basic assembly, the manual drive mechanism can be changed into an automatic drive mechanism. The basic assembly (1) is equipped with a drive shaft (4) that is freely rotatably supported in the housing (3), and one end extends out of the housing (3), and is linked with the drive shaft (4) to transmit the external driving force Drive force transmission mechanism to stem connector (6). The front end portion of the drive shaft (4) extending from the casing (3) to the outside is detachably equipped with an operating handle (7) for applying power by manual operation. The housing (3) of the drive shaft (4) is provided with a keyhole (8) on the outside, which can be connected with the gear of the drive shaft (6) through the lock key (1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com