Quick-cutting tool positioning structure

A tool positioning and positioning mechanism technology, applied in auxiliary devices, metal processing, manufacturing tools, etc., can solve the problems of waste of space and equipment resources, inability to share positioning trolleys, waste of resources, etc., achieve high switching efficiency and save manual switching time , The effect of convenient model switching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

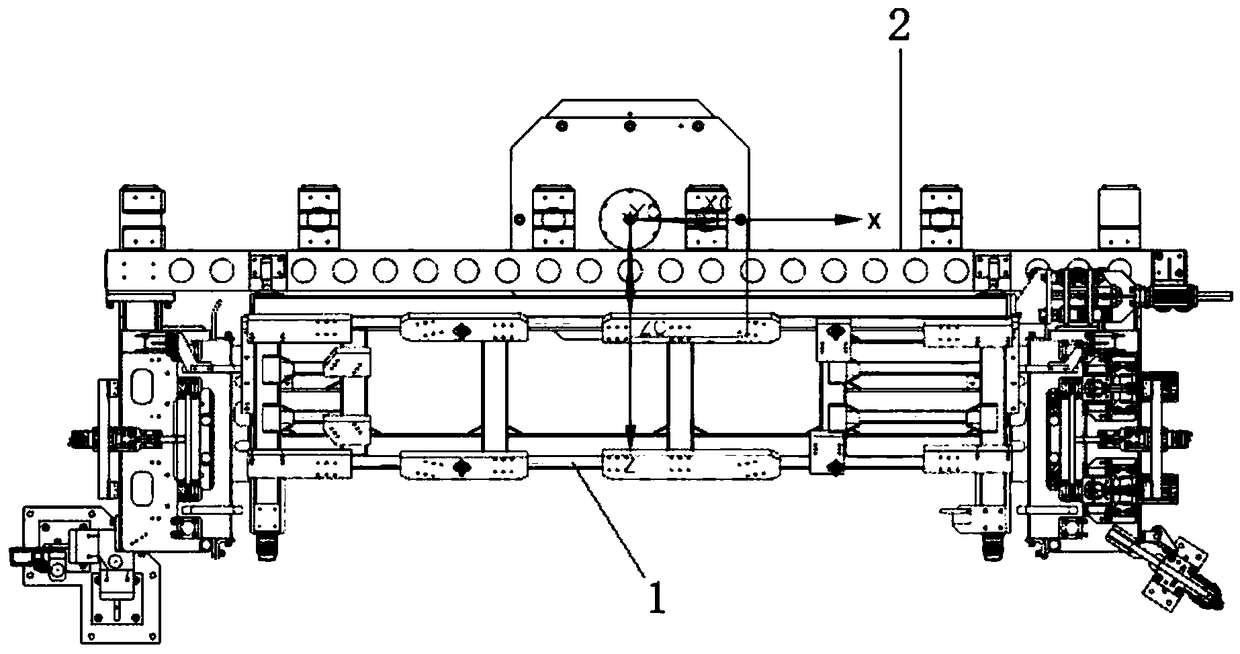

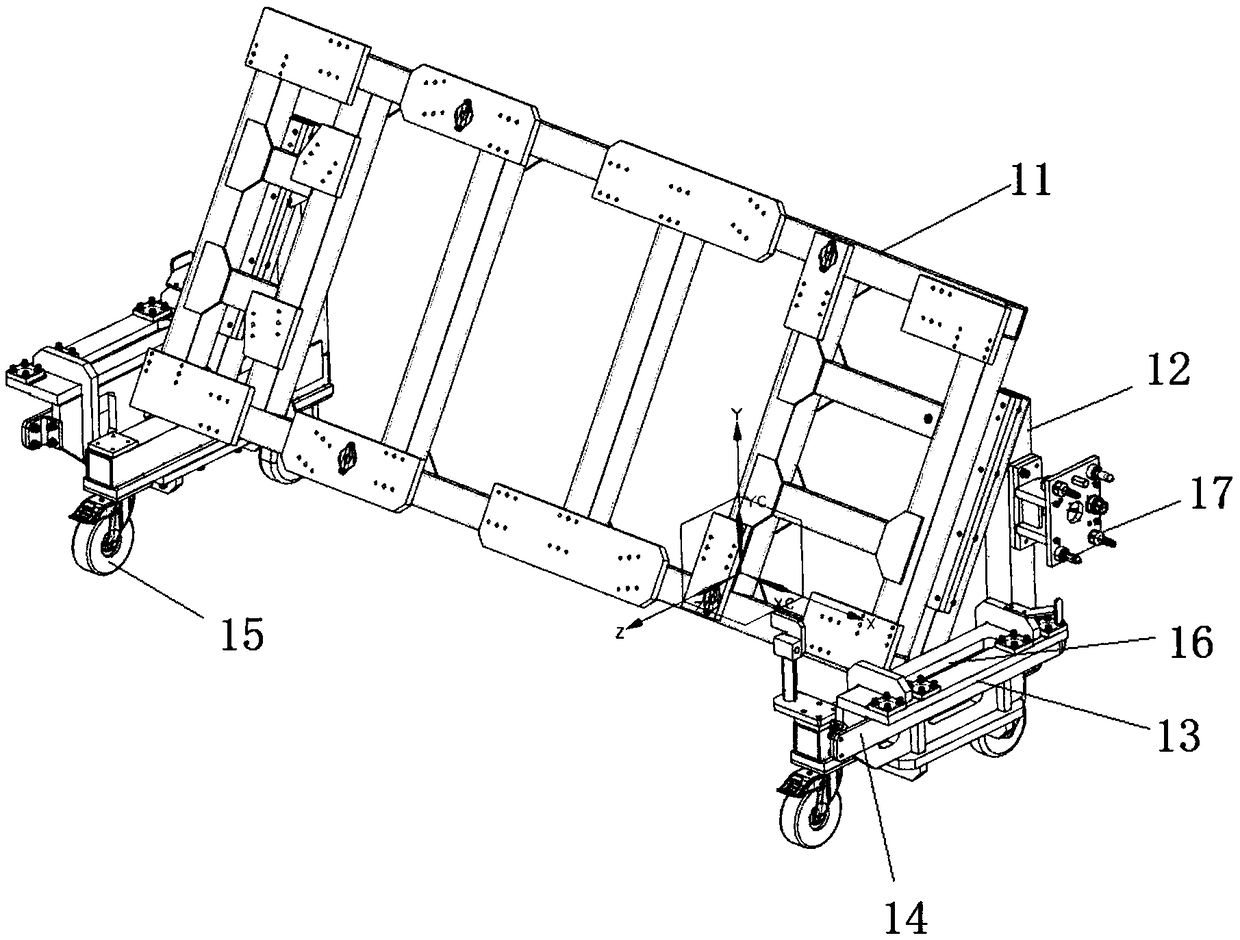

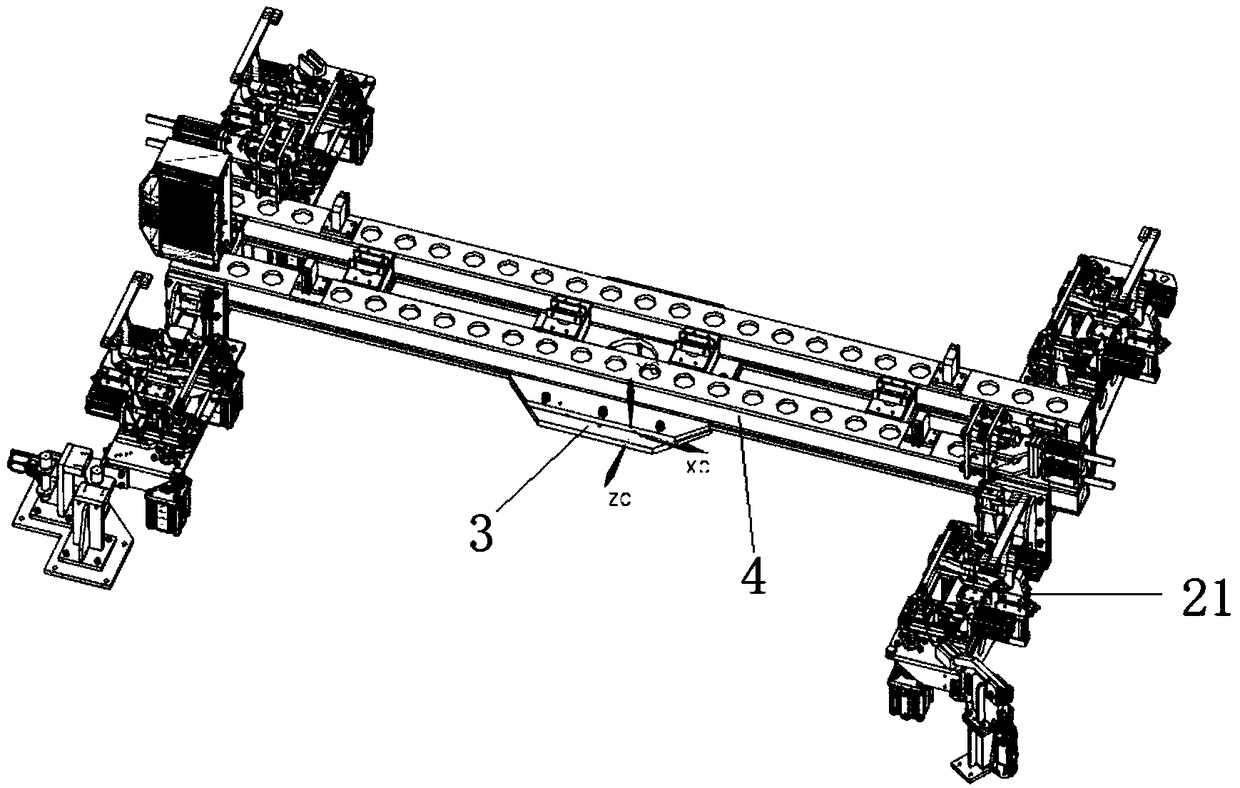

[0018] Such as Figure 1 to Figure 4 As shown, the present invention discloses a quick-cut tool positioning structure, including a ground fixing mechanism 2 and a switchable tool 1. The switchable tool 1 includes a clamp frame 11 and tripods 12 arranged at both ends of the clamp frame 11. The tripod 12 is a right-angled triangular support. The tripod 12 includes a crossbeam, a longitudinal beam and an oblique beam. The longitudinal beam and the crossbeam are arranged perpendicularly. On the inclined beam of a tripod 12, the lower end of the beam of the tripod 12 is provided with a universal wheel 15, and the opposite side of the tripod 12 and the clamp frame 11 is provided with a pressing plate 13 and is located on the pressing plate. The guide plate 14 at the lower end of 13, the tripod 12 is provided with a limit block on the longitudinal outer side, and the pressing plate 13 is provided with two Y-direction lifting pin holes and Y-direction bar-shaped positioning pin holes ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com