Thermal mass gas flow sensor and method of forming same

A gas flow, sensor technology, applied in the field of flow sensors, can solve problems such as damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The specific values and configurations discussed in these non-limiting examples can vary and are used merely to illustrate at least one embodiment of the invention and are not intended to limit the scope of the invention.

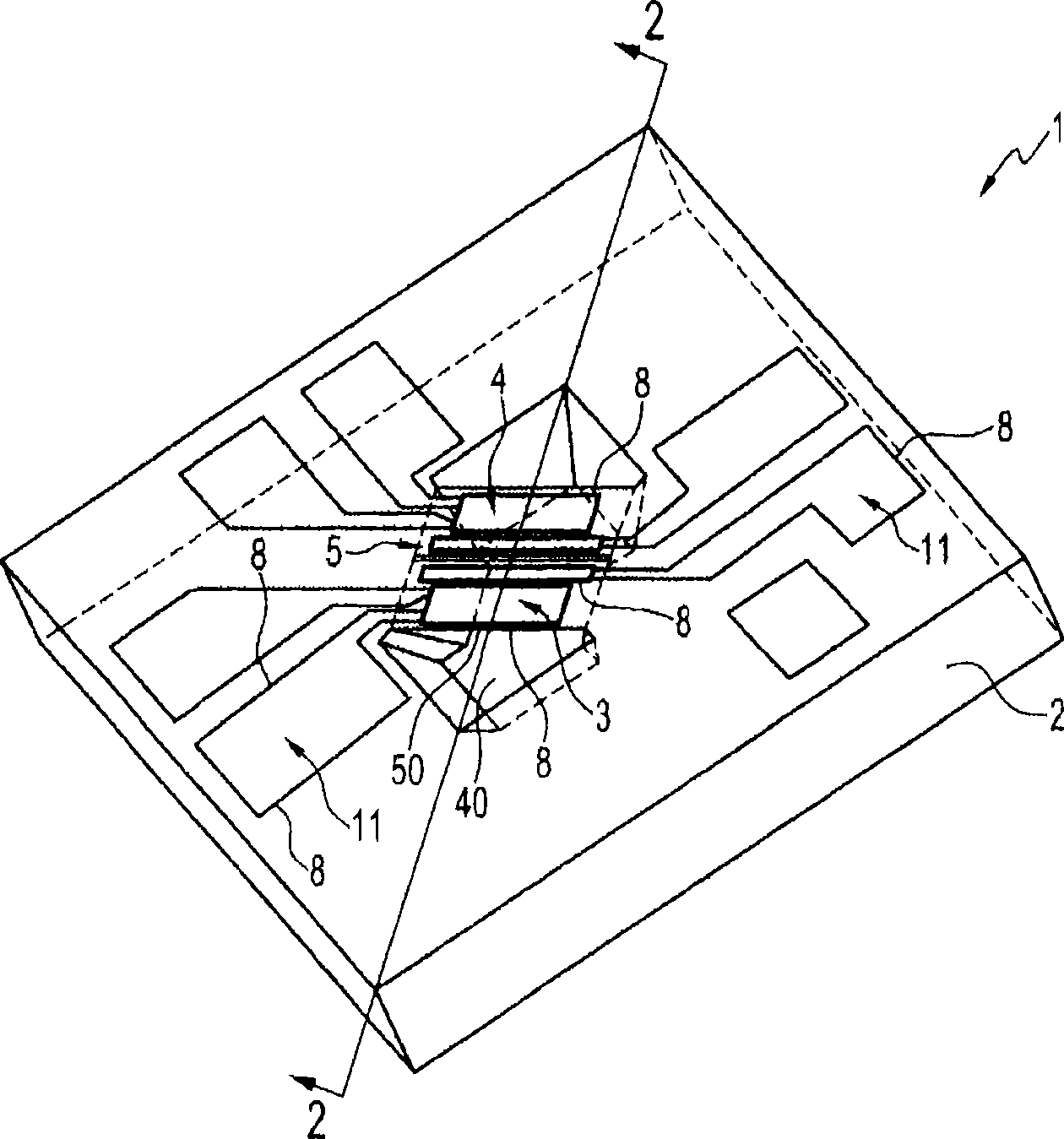

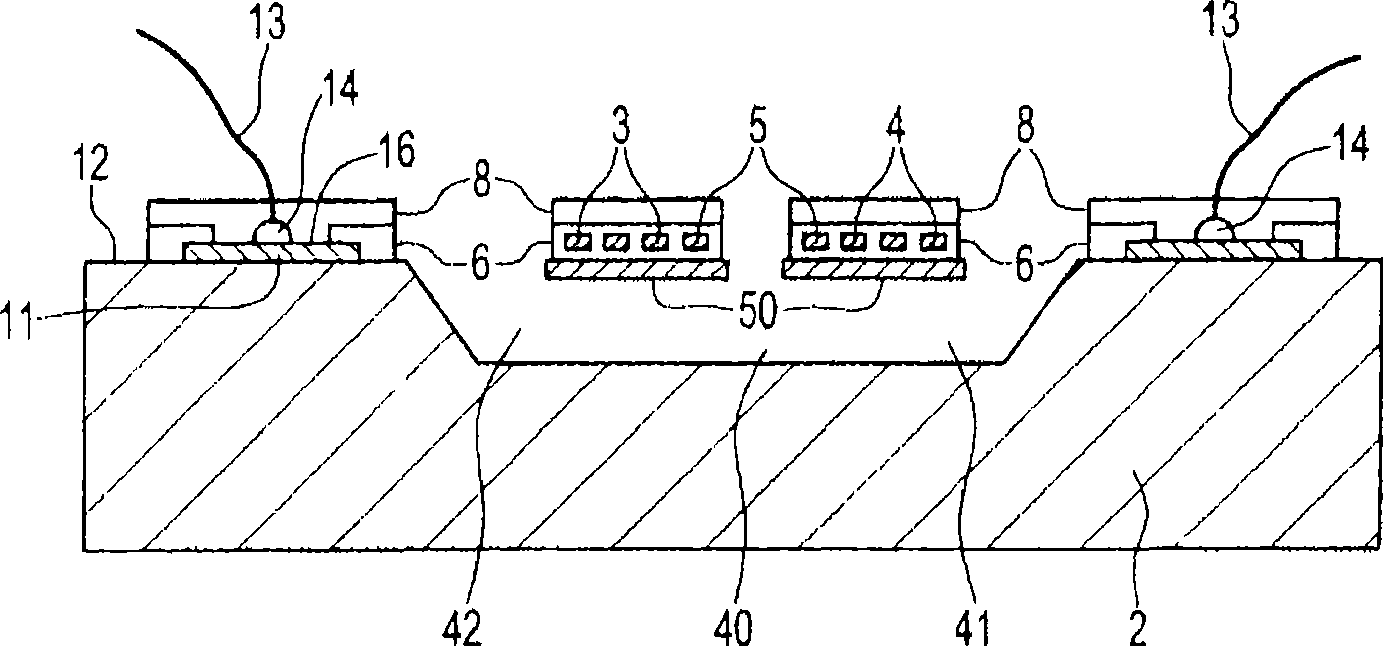

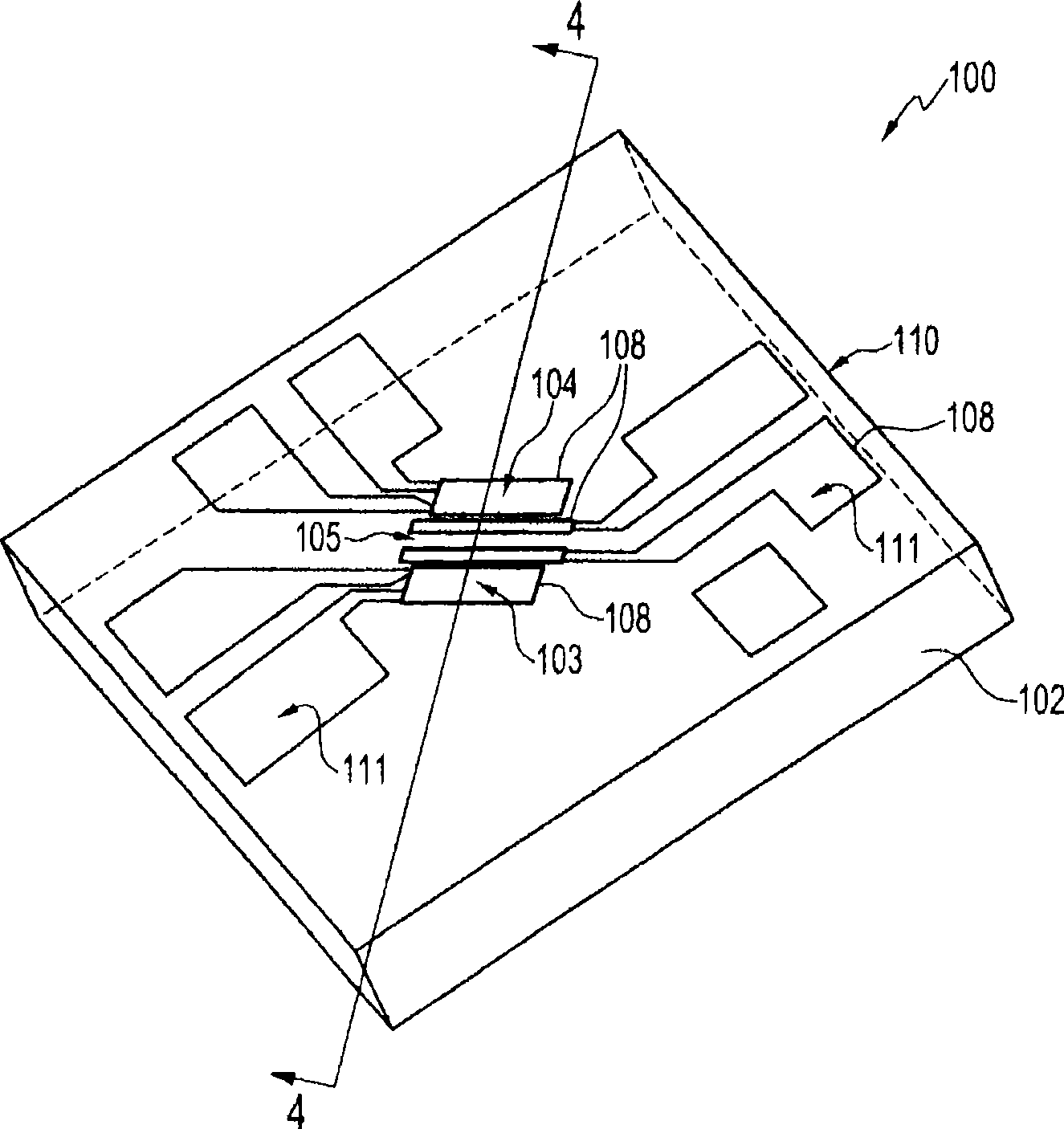

[0031] See attached picture, figure 1 shows a perspective view from above a thermal mass gas flow sensor according to one embodiment and figure 2 shows the case where the leads are bonded to the sensor along the figure 1 A cross-sectional view taken along line A-A in . As a general overview, a thermal mass gas flow sensor 1 has a substrate 2 and a heater 5 disposed on the substrate 2 between a pair of thermal sensing elements 3, 4 which are also installed on the substrate. A protective layer 8 is provided on the heater 5 and the thermal sensing elements 3 , 4 . This protective layer 8 is made of a high temperature resistant insulating or dielectric layer, preferably an organic layer, such as a polymer based layer. The protective layer minimiz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com