Guide mechanism for scum scraping chain

A technology of guiding mechanism and slag chain, which is applied in the direction of coating, liquid coating device on the surface, etc., can solve the problems of slag chain falling off, slag scraping chain falling off, paint waste, etc., and achieve the effect of preventing falling off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

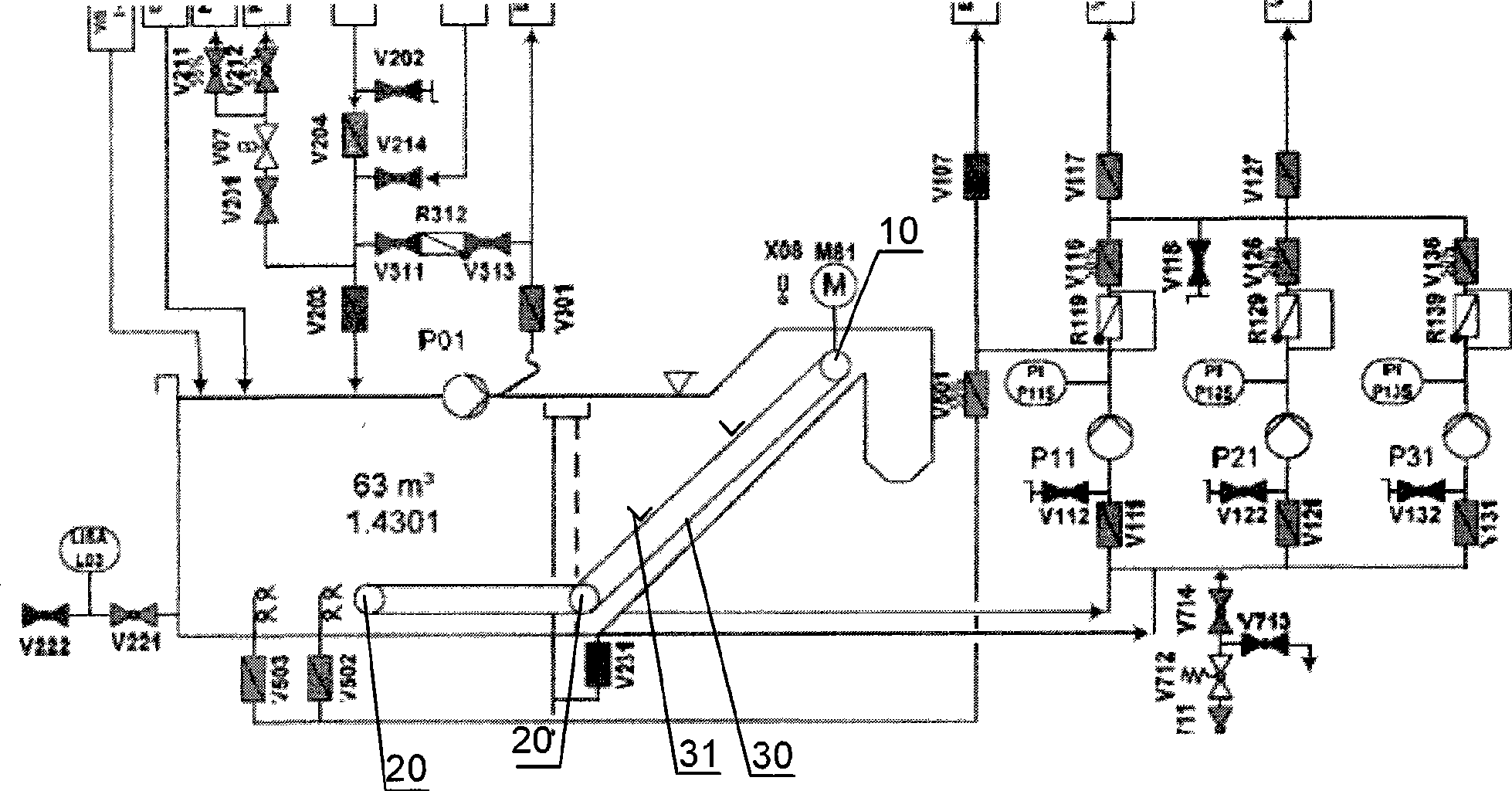

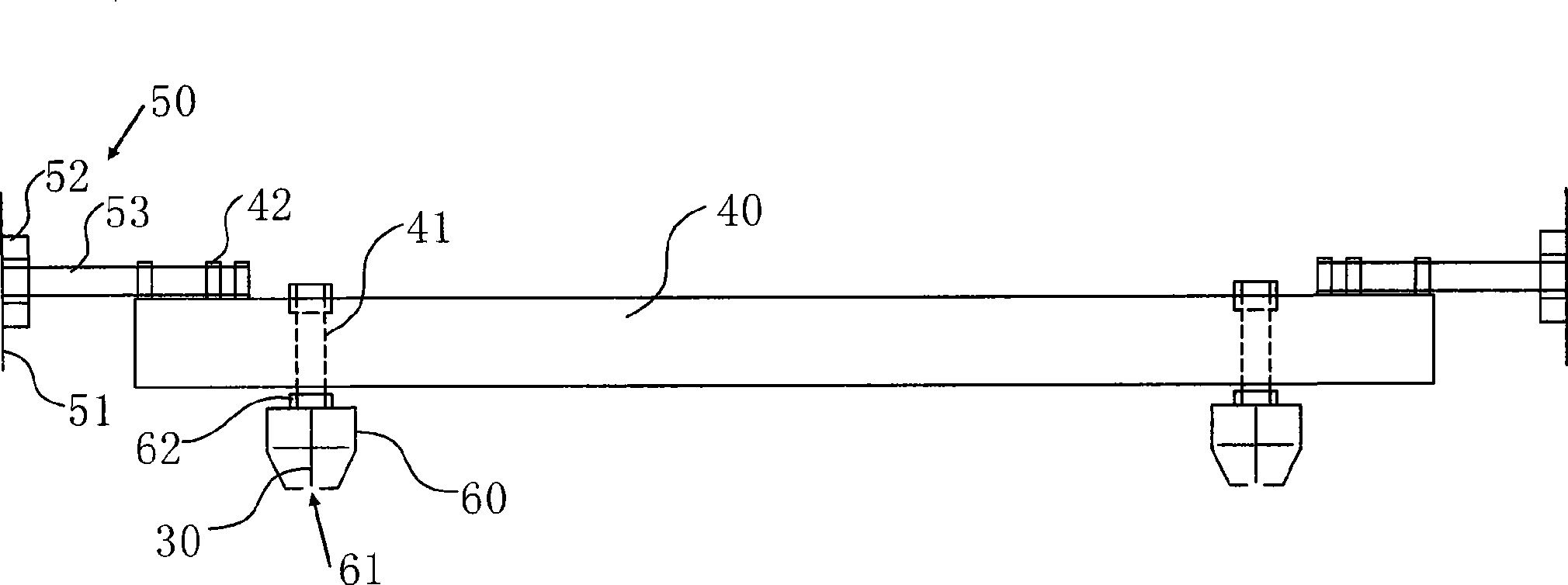

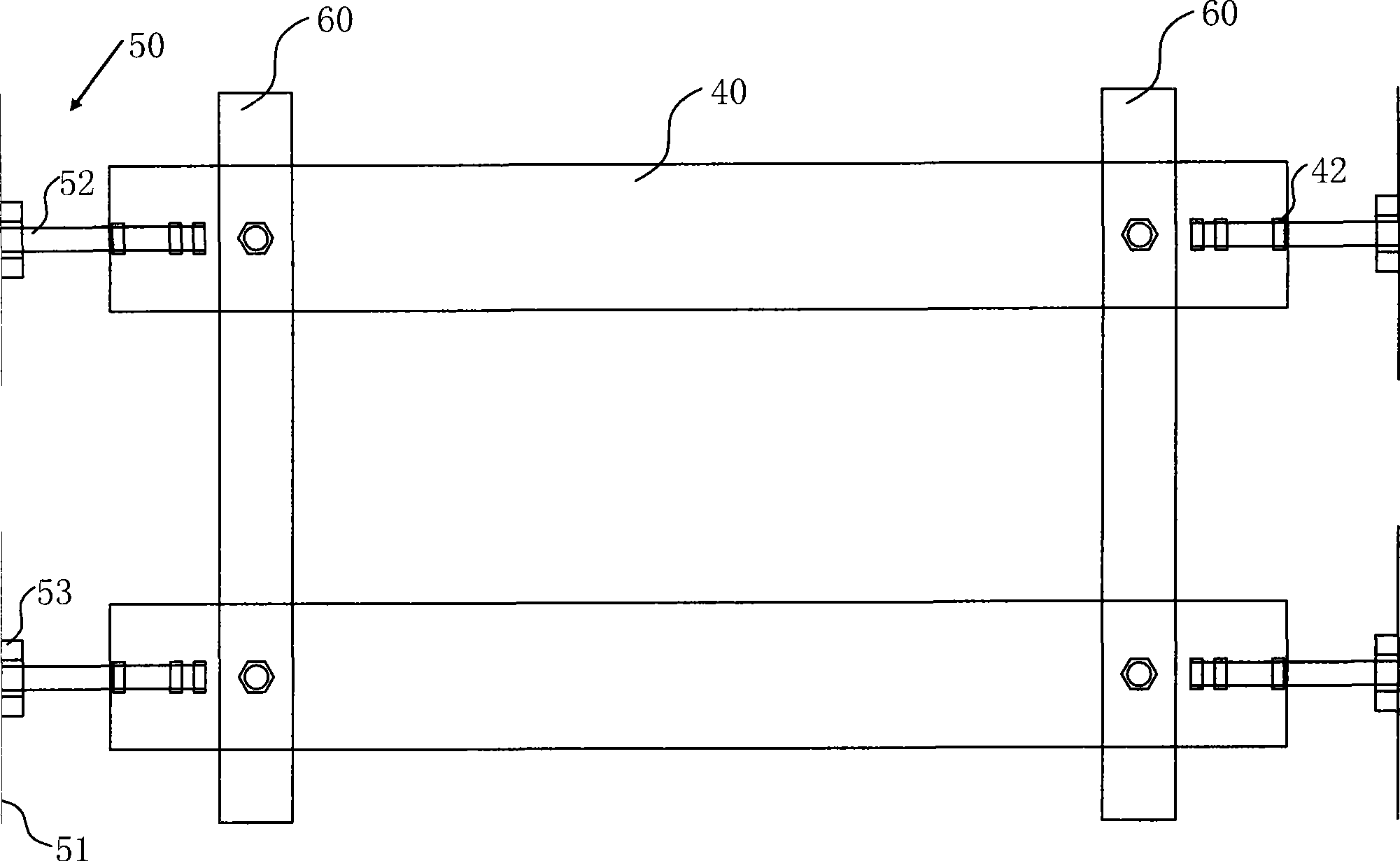

[0011] A slag-scraping chain guide mechanism, including a driving wheel 10 and a driven wheel 20 placed horizontally on the top and bottom of the groove respectively, two parallel slag-scraping chains 30 bypassing the driven wheel 20 and the driving wheel 10 respectively, and the slag-scraping chain 30 It is a transmission chain, and the scraper 31 is placed horizontally on the two slag scraping chains 30. The scraper 31 is an angle steel, and its concave part faces the side of the tank top. In the waste paint recovery tank, a guide rail 60 for the passage of the scraper chain 30 is provided on the scraper chain 30 located at the front end of the driving wheel 10. The guide rail 60 is an open ring or a groove-shaped rail in cross section. In the present invention, the guide rail 60 adopts the latter, such as figure 1 , 2 As shown, here, the tank refers to the waste paint treatment tank, and the front end refers to the part on the slag scraping chain 30 that is about to cooper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com