Multibar bearing and motion guiding mechanism of tilt-up door

A technology of a guiding mechanism and a multi-bar mechanism, which is applied in the field of urban rail vehicle door systems, can solve problems such as inability to rotate, and achieve the effects of avoiding collision, convenient installation and high reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

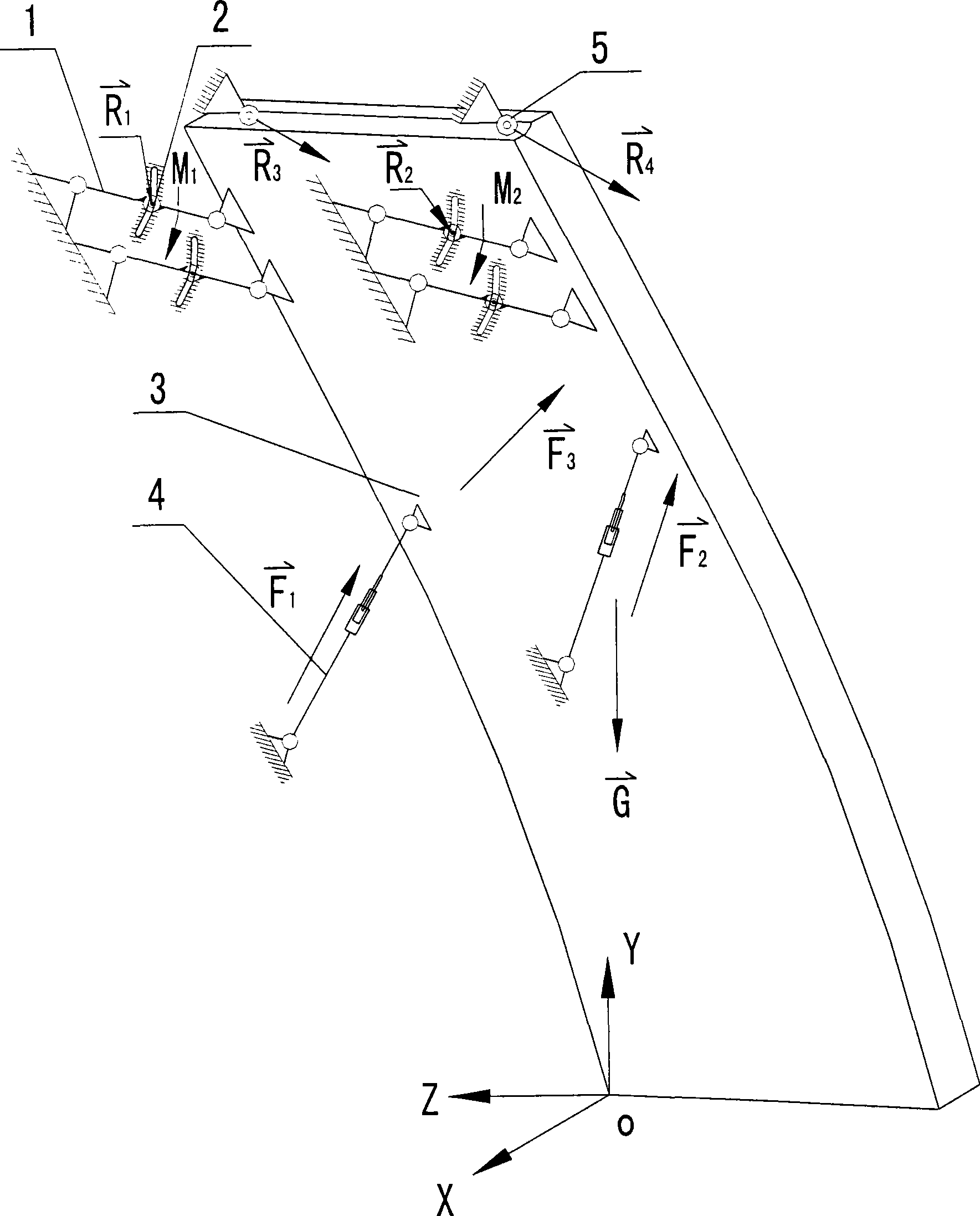

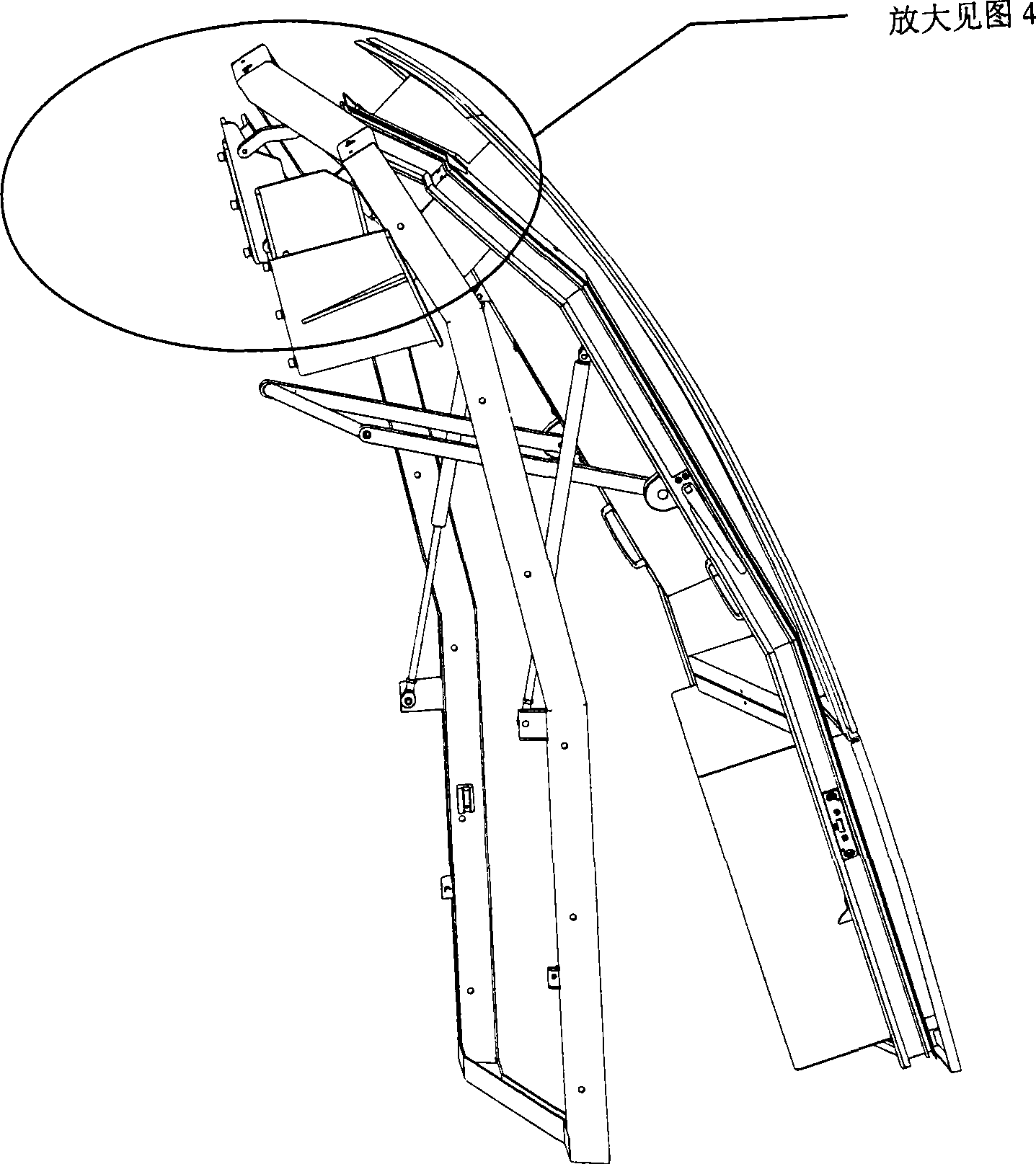

[0012] Control attached figure 1 , In the Cartesian coordinate system, in two planes parallel to the YZ plane, there are 2 multi-bar mechanisms 1 to constrain the connecting rods in the Z-axis direction 2 to restrict the linkage mechanism to move in the YOX plane and increase the connecting rods The stiffness.

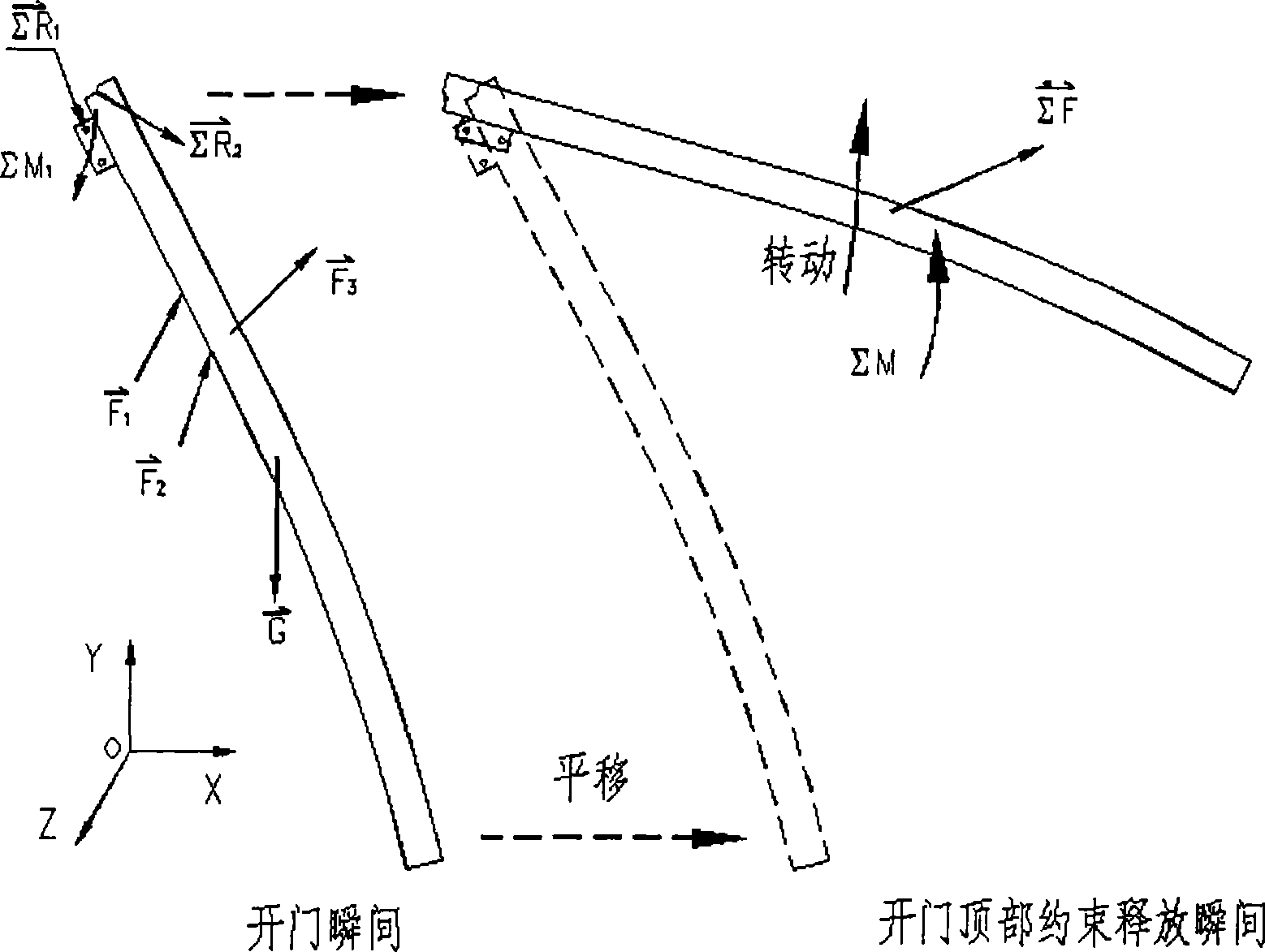

[0013] The top restraint 5 is set in two planes parallel to the XY plane, and is pressed on the top of the door leaf 3. At the moment of the initial movement of the door leaf, the reaction force R of the top restraint 5 3 And R 4 Balanced door opening thrust F 3 Pre-stored force F on both sides 1 And F 2 The component force in the Y-axis direction prompts the door leaf 3 to perform translational movement first. After the door leaf 3 is translated along the X-axis direction to release the constraint, the door opening thrust F 3 Pre-stored force F on both sides 1 And F 2 The door leaf 3 flips upward under the combined force of, so as to realize the movement of the door leaf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com