Electromotor and permanent magnet series connection type vascular stent tube material inner wall magnetic particle grinding and polishing machine

A technology of vascular stents and permanent magnets, applied in grinding/polishing equipment, surface polishing machine tools, grinding machines, etc., can solve the problems of large length, small diameter of slender tubes, and inability to uniformly remove and polish the surface of the inner wall

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

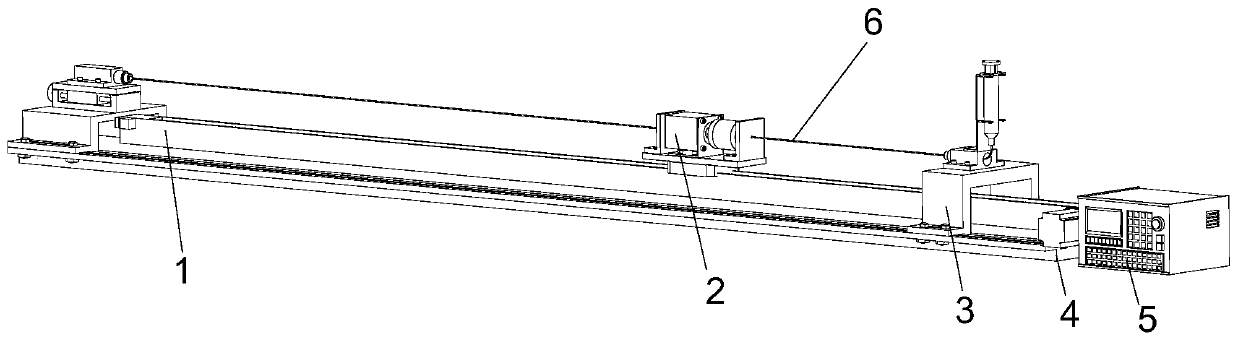

[0025] Such as figure 1 As shown, the overall structure of the present invention includes a rotating magnetic pole moving transmission device (1), a rotating magnetic pole device (2), a vascular stent tube clamping and feeding device (3), a machine base (4) and a numerical control system (5).

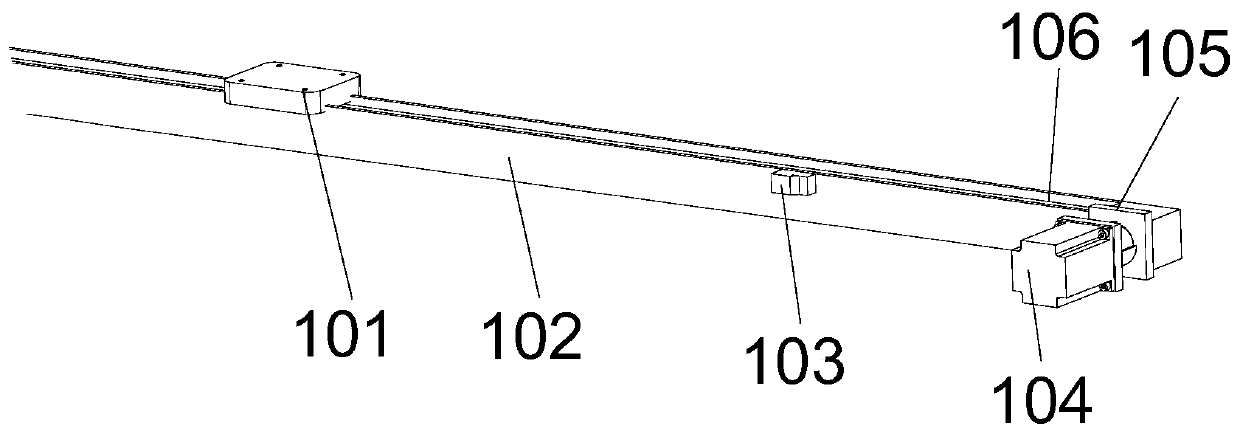

[0026] Such as figure 2 As shown, the rotating magnetic pole moving transmission device (1) consists of a slide table (101), a synchronous belt guide rail (102), a limit switch (103), a stepping motor (104), a motor flange seat (105), a shaft coupling Composed of synchronous belt (106), the synchronous belt guide rail (102) is fixed on the base (4), the stepper motor (104) is fixed on the end of the synchronous belt guide rail (102) through the motor flange seat (105); (101) is installed on the synchronous belt guide rail (102) and connected to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com