Heat exchanger performance testing device for air conditioning

A technology of heat exchangers and heaters, applied in measuring devices, testing of machines/structural components, instruments, etc., can solve problems such as high testing costs, inconvenient testing, and inability to adjust the capacity of the tested machine, and reduce testing costs , Ease of electrical control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

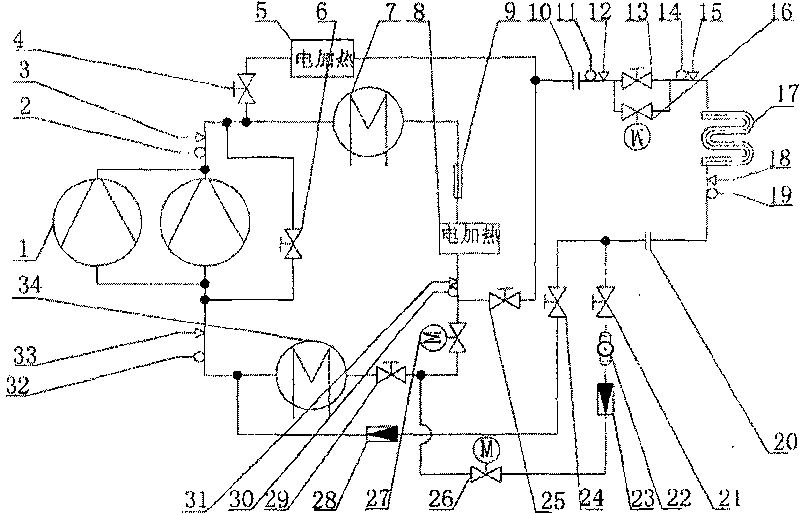

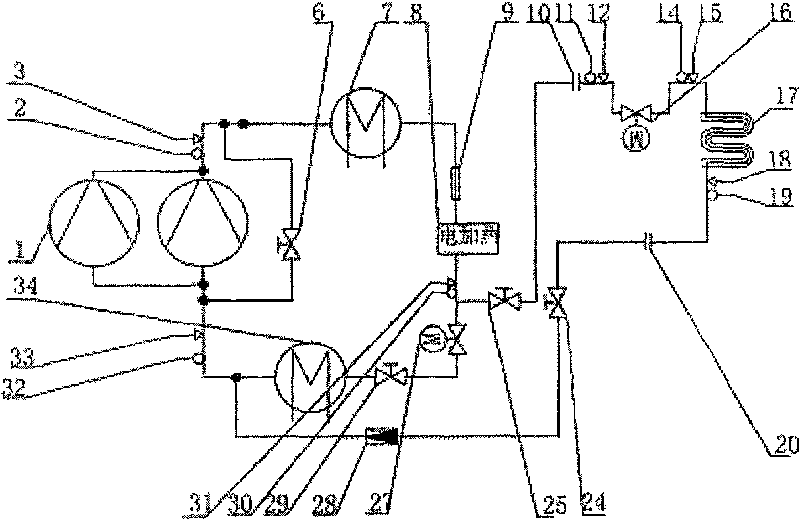

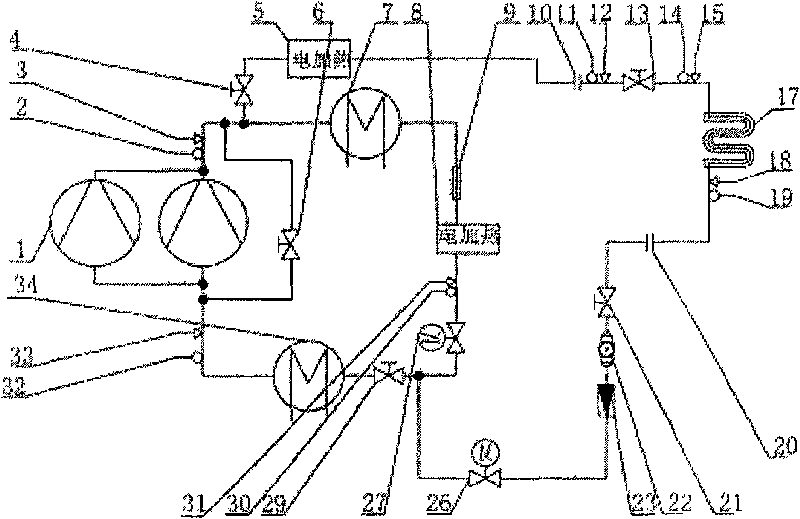

[0024] See figure 1 , The air conditioning heat exchanger performance test device includes two parallel-connected refrigeration compressors 1, condenser 7, evaporator 34 and heater;

[0025] The outlets of the two parallel refrigeration compressors 1 are connected to the inlet of the condenser 7 through a pipe, the outlet of the condenser 7 is connected to the inlet of the subcooler 9, and the outlet of the subcooler is connected to the heater B8 and the other of the heater B8. One end is connected to the inlet of the evaporator 34, and the outlet of the evaporator 34 is connected to the inlets of two parallel refrigeration compressors 1;

[0026] Two parallel refrigeration compressors 1 are connected in parallel with regulating valve A6;

[0027] The outlets of the two parallel refrigeration compressors 1 are equipped with discharge temperature measurement point 2 and discharge pressure measurement point 3, and the inlet is equipped with refrigeration compressor suction temperature ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com